Solder-free approach improves diode-bar assembly

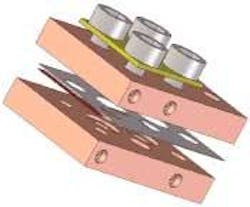

A new solder-free mounting technology developed by Monocrom (Vilanova I la Geltrú, Spain) simplifies the assembly of laser-diode bars. Developed in conjunction with high-power laser-diode assemblies designed by Monocrom, the mounting technology eliminates the need to attach the laser-diode bars using solder; instead the bars are clamped within two copper blocks that serve as both electrodes and heat sink. In addition, very low thermal resistance (less than 0.4 K–m/W) can be achieved by the use of new water-cooled electrodes that do not require microchannels.

The result is the virtual absence of the "smile effect," according to Thomas Etzkorn, president of Monocrom. In traditional solder-based mounting, the laser bar shows some curvature (the so-called smile) due to differences in the thermal expansion coefficient of the solder material and the copper; in the new technology, the smile has been reduced to below 0.2 µm. A second advantage is the lower stress during quasi-continuous-wave (quasi-CW) applications. With traditional mounting techniques, the difference between the expansion coefficient of the copper and solder material can produce mechanical stress on the laser bar.

"In our technology, the [residual] smile is created by the flatness of the copper (on the order of ±150 nm), resulting in higher peak powers in the quasi-CW mode (up to 120 W at 20 ms/bar) and better focusability," Etzkorn said.

This approach offers three advantages in terms of thermal management, he adds. In the traditional mounting technique, the thermal resistance of the mount is limited by the thermal resistance of the solder material. In soldered laser diodes, the contact resistance is given by the high thermal resistance of the solder material. With the Monocrom approach, the contact resistance—which depends only on how good the laser bar–copper contact is—can be reduced by improving the surface quality of the copper electrode. Furthermore, the contact resistance could be reduced even further using nanotechnology methods.

Another advantage is that the waste heat can be dissipated through the two heat sinks. In contrast to traditional technology, in which the waste heat is only dissipated to one heat sink, in the Monocrom approach the bar is cooled from both sides. There is also no need for microchannels. Ordinarily, to achieve thermal resistance below 0.4 K–m/W, the electrodes require microchannels, which can easily be obstructed by particles in the cooling system. Deleterious erosion of microchannels can also occur. As a result of these problems, in most cases the lifetime of the laser diode is not limited by the lifetime of the laser bar itself but by the lifetime of the heat sink. In the Monocrom water channels, the possibility of obstruction is greatly reduced, resulting in higher lifetimes of the laser diode.

Monocrom has used this approach in the design and assembly of its laser-diode products. According to Etzkorn, the company's lasers have already shown benefits as pump sources and for direct-diode applications, especially those that require quasi-CW performance in the 10-ms range where compact, high-power designs are required.