Paul Burrows of Pacific Northwest National Laboratory (PNL; Richland, WA) described promising developments for flexible organic LEDs at the MRS Spring Meeting (San Francisco, CA) in April.1 Flexible OLED displays have enormous commercial potential if they can overcome lifetime and manufacturing challenges.

The "Achilles heel" of OLEDs is that they must be protected from water and oxygen, which shorten the lifetimes of these devices. Plastic substrates are permeable to moisture, and various attempts at flexible single-layer moisture barriers have not been successful at extending OLED lifetimes to desired lengths.

Layering polymers and ceramic

The PNL group, however, has for about five years been building OLEDs with multilayer barriers that have longer lifetimes than those with single-layer barriers. The lifetime was assumed to be the result of lower permeability, although the lifetime doesn't fit the standard model for permeability. In fact, Burrows announced at the meeting that the multilayer barriers aren't unusually impermeable—they extend the lifetimes of the OLEDs because of dynamic time-lag effects.

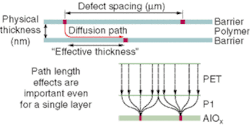

The group has been making OLEDs on plastic substrates with barriers made of multiple layers of polymer and ceramic.2 The aluminum oxide layers block moisture. ("Make any film thin enough and it will be flexible," explains Burrows, "but for inorganic materials that has to be very thin.") This thin ceramic layer isn't perfect: defects allow some water to penetrate. Between layers of ceramic, the devices have thick polymer layers that provide a flat surface and decouple defects of one ceramic layer from the next.

Stopping water

The typical method for modeling how permeable a material is to moisture and oxygen assumes a system at equilibrium except for a constant difference in partial pressure across the membrane. But this is not the situation for diffusion into a sealed package like an OLED. So the group went back to basic diffusion calculations. The mass transmitted through the membrane, they found, can be expressed using terms for the steady-state flux and a lag time.

The multilayer barriers were extending the lag time. By engineering the design to decrease the steady-state flux and increase the lag time to years, lifetimes of these OLEDs on permeable substrates can be extended.

Imagine your roof is leaking rain onto a very valuable floor that would be damaged by water. You wish to protect it but all you have to catch the drip is a pile of punctured buckets and rags. One bucket will start to leak almost immediately. However, you can protect the floor longer by making a stack—get a bucket, and put a rag in it. Add another bucket on top, with another rag in it. Repeat. The rainwater will eventually get through, but (depending on the size and number of the holes and the number of buckets) the stack may protect the floor until the sun comes back out.

The transmission of moisture through the ceramic and polymer layers is similar to rainwater leaking through the bucket-and-rag stack. If the defects are offset, then the moisture has to travel farther through the polymer to get from a defect in one ceramic layer to a defect in the next ceramic layer, increasing the effective thickness of the polymer layer (see figure). Therefore, the permeability—and, more important, the lag time—depends on both the size of the defects and their offset distances. Increasing the number of layers reduces the steady-state flux, and the farther apart the defects, the longer the lag time.

The group is continuing to work on the devices. A paper detailing further results has been submitted to a peer-reviewed journal.

REFERENCES

- P. E. Burrows et al., MRS Spring Meeting 2004, Invited paper I1.2.

- M. S. Weaver et al., Appl. Phys. Lett. 81, 2929 (2002).