Small excimers shine in scientific applications

Compact excimer lasers- lightweight, rugged, and air-cooled, with low power consumption, short pulse lengths, and easy to switch in wavelength-have just the qualities needed for scientific investigations, especially out in the field.

The important role that UV radiation has come to play in industrial applications (such as photolithography, materials processing, and machining) has spurred major efforts to scale up the pulse energy and average power of excimer lasers. At the same time, however, a need has developed for small, economical excimer lasers for scientific applications.

Research scientists in fields such as environmental monitoring, surface science, and the study of reaction dynamics have found that excimer lasers are ideal sources for the application of techniques such as fluorescence spectroscopy, flash photolysis, and laser-ionization mass spectrometry. The requirements of these applications have driven the development of compact, flexible excimer lasers.

Electrical-wind electrode

Improvements in halogen-resistant materials and optical components have made possible the commercialization of reliable compact excimers, which are now available in footprints of less than 1 ft2 and have found a wide range of industrial and scientific applications. In one example, a highly miniaturized excimer laser (the PSX-100 from MPB Communications) has an integrated internal-preionization/peaking-capacitor arrangement and a low-inductance discharge circuit, resulting in optical pulse lengths in the 2.5- to 5-ns range (depending on wavelength). With no internal moving parts in the laser chamber, gas circulation in this laser is driven by an “electrical-wind” electrode that also serves as a dust collector to extend gas-fill lifetimes. The air-cooled excimer produces pulse energies of 1 mJ at 157 nm and up to 5 mJ at 248 nm at repetition rates to 100 Hz and a timing jitter of less than ±1 ns.

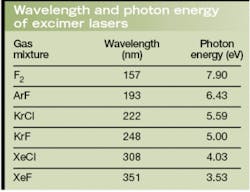

Researchers find these small excimers to be an ideal tool for surface sciences. Typical bonding and ionization energies for many molecules are in the range of 3 to 15 eV. Excimer photon energies are high enough to overcome the dissociation energy of molecules as well as the first ionization energy of many elements, leading to desorption and ablation of the materials on the surface (see table). The ablation process is more complex and not yet totally understood, as the laser beam also excites vibrational and rotational states of the molecules, leading to energy transfer to molecules below the surface and ejection of molecules or clusters of molecules. Control over these processes will be possible with a better understanding of the various mechanisms.

In many scientific investigations, the ability to study a particular phenomenon at different laser-excitation wavelengths is advantageous. Excimer lasers offer six UV wavelengths ranging from 157 to 351 nm, but it is important that the laser design allow for an easy change from one wavelength to another. For instance, when the laser is equipped with a broadband total reflector, changing the operating wavelength requires nothing more than changing the gas mixture, as the internal discharge assembly and the driving electronics are designed to accommodate the different excimer-gas fills.

Science with compact excimers

Erik Jensen of the University of Northern British Columbia (Prince George, BC, Canada) uses this laser at 222, 248, and 308 nm to study the photodissociation dynamics of methyl iodide (CH3I) on copper crystal surfaces.1 Each specific excimer wavelength allows him to study a different portion of the A-band absorption of the CH3I molecule. The crystal surface is carefully prepared with one or two molecular layers on the copper substrate and the excimer beam excites a particular transition of the molecule. A defocused beam with a fluence as low as 0.8 mJ/cm2 causes dissociation of the CH3I and neutral-molecule desorption. The photoproducts fly off to a quadrupole mass spectrometer for analysis. More information on the transitions can be analyzed with the use of a polarizer between the excimer and the surface being studied.

Selective laser desorption of ionic surfaces is also being studied at Pacific Northwest National Laboratory (Richland, WA) by Wayne Hess and his team. Precise control of the laser wavelength and fluence leads to desorption of bromine from the surface of potassium bromide (KBr) crystals.2 The desorption yield is controlled with the fluence of the laser beam, while the velocity of the desorbed particles is controlled with the photon energy. Similar work has been done on sodium chloride crystals at a photon energy of 7.9 eV. The effect of fluence has been studied for KBr at a photon energy of 6.4 eV, which corresponds to the 193-nm excimer wavelength. Typical fluence is less than 100‑µJ/cm2, but desorption-yield-versus-fluence curves established over a wide range show a linear behavior over a broad fluence and evidence of multiphoton processes when the fluence increases.

The studies show that not only is the illumination wavelength critical to initiating a precise excitation, but also the fluence and the pulse length determine the probability of a molecule being excited. At very low fluence, single-photon excitation is responsible for desorption of atoms and molecules off the surface. When fluence is increased, multiple-photon excitation leads to the ejection of larger molecular clusters.

Low fluence is also required in the study of metal clusters performed by Mark Knickelbein of Argonne National Laboratory (Argonne, IL).3 In his experiment, Knickelbein analyzes the physical and chemical properties of metal clusters. Small metallic clusters, in which all atoms are at the surface and available for reactions, have shown chemical and physical properties that often differ from the behavior of the material in bulk form. With a molecular beam apparatus based on the so-called Stern-Gerlach experiment, the metal clusters are vaporized from a metallic surface with a pulsed 532-nm laser beam and then pass through a magnet, which induces small deflections that give information on the magnetic properties of the clusters in relation to their size and geometry (see Fig. 1). A 193-nm excimer beam then photoionizes the clusters prior to entering a position-sensitive time-of-flight mass spectrometer. A very low fluence is again necessary for the photoionization to avoid fragmentation of the clusters, a phenomenon that would lead to erroneous measurements of cluster abundances and thus incorrect values of physical and chemical properties.

Excimers in the field

The usefulness of compact excimers also resides in the fact that they are ideal for integration in systems in which size and weight really matter, such as in the particle-analysis-by-laser-mass-spectrometry (PALM) system developed by the National Oceanic and Atmospheric Administration (Washington, DC).4 Installed in the nose of a WB-57 high-altitude research aircraft, the PALM instrument provides detection and analysis of particles in the stratosphere. Particles are detected by an Nd:YAG laser and the resulting scattered beam is used to trigger the excimer laser, which ionizes the particle for analysis in a mass spectrometer.

Excimer qualities such as long gas-fill lifetime, compactness, and ruggedness are keys to the success of the PALM experiment. Also critical is keeping the delay short between the external trigger and the laser pulse.

Although 157 nm would be a better wavelength choice because of the higher photon energy, the laser is used at either 193 or 248 nm to avoid the extra weight associated with providing the evacuated beam path required for the propagation of 157-nm radiation. The fact that the excimer laser is air-cooled allows further reduction of the total weight of the instrument package. The body of the laser is enclosed in a pressurization chamber to enhance the cooling airflow at such altitudes. Because weight restrictions preclude pumps or gas cylinders on board, the laser is filled with fresh gas in the lab prior to the flight.

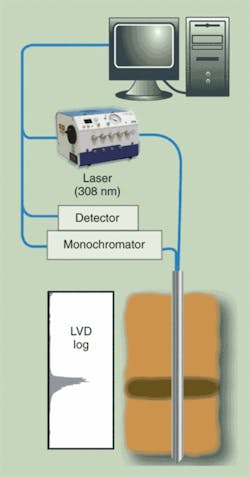

Compact excimers are also proving useful in the detection of soil contaminants when integrated in systems such as the rapid-optical-screening tool (ROST) developed by Dakota Technologies (Fargo, ND), in which an excimer laser is used at 308 nm for laser-induced fluorescence (see Fig. 2).5 The beam is launched into an optical fiber and delivered via a direct pushrod terminated with a sapphire window. The UV radiation is absorbed and fluorescence of the polycyclic aromatic hydrocarbons in the oils sent back to a spectrograph and analyzed. The ROST system is useful for real-time detection of all petroleums, oils, lubricants, creosotes, and coal tars. The complete system is installed on a pickup truck with all necessary equipment for logging the contamination of soils versus depth. Here again, size, weight, and gas lifetime are critical parameters for the excimer laser.

As pure research evolves into field applications, issues such as faster processing, lower cost of ownership and ease of integration are becoming more critical. Compact excimers with higher repetition rates, higher pulse energy, and modular design, such as MPB’s Model Ximer-300, are now providing solutions for system integrators.

The contribution of compact excimer lasers to understanding the underlying chemistry of desorption, electronic transitions, phase changes, and fragmentation mechanisms is paving the way to the control of desorption and ablation phenomena at the microscopic level, which in turn is opening the door to the manufacture of new artificially engineered materials and structured coatings.

REFERENCES

1. E. T. Jensen, Surface Science 528, 204 (2003).

2. W. P. Hess et al., J. Chem. Phys. 115, 9463, (2001).

3. chemistry.anl.gov/ClusterStudies/SpectroscopicAndStatic.html

4. www.al.noaa.gov/palms

5. www.dakotatechnologies.com/ROST.htm

JULIE GRONDIN is laser-products manager at MPB Communications Inc., 147 Hymus Blvd., Pointe-Claire, QC, Canada, H9R 1E9; e-mail: [email protected].