Combustion research fuels life into dye lasers

Combustion research fuels life into dye lasers

Proven performance, reliability, and ease of use keep dye lasers valuable for certain applications such as imaging spectroscopy in combustion research.

Peter Genter, Heinrich Voges, and Bernd Nikolaus

While few in the laser industry would challenge the inevitability of the long-term trend toward solid-state laser technology, many might debate the time scale for a given laser type to be replaced by a solid-state device in an important application. Several commercial markets for helium-neon lasers, for example, have persisted long after the advent of low-cost red-emitting diode lasers. Similarly, the range of currently available tunable solid-state devices would seem to suggest the end is near for commercial pulsed dye lasers. Nonetheless, sales of pulsed dye lasers remain strong, and laser-dye suppliers also indicate healthy sales of their products.

There are several reasons for this continued revenue strength; one is healthy growth of specific applications for dye lasers. In a study of combustion, for example, combining tunable lasers with high-performance imaging techniques allows a wide range of combustion systems to be studied and consequently improved (see photo).

Tunable laser technology

For many applications, particularly those involving high-resolution atomic or molecular spectroscopy, key dye-laser performance requirements are high peak power and narrow linewidth. These can only be achieved easily using multiple stages; the narrow linewidth is produced by a low-output-power oscillator that then pumps one or more amplifiers.

Historically, a troublesome issue with pulsed-dye-laser performance has been amplified spontaneous emission (ASE). This is a consequence of the short pulse duration of the pump lasers (2-8 ns for Nd:YAG lasers and 10-30 ns for excimer lasers). ASE manifests as a broadband background component spanning many nanometers (see Laser Focus World, Sept. 1995, p. 117). Successive generations of oscillator designs have steadily reduced ASE to levels as low as 1 part in 104. The linewidth of such a laser is typically 0.1 cm-1, or 0.02 cm-1 with an etalon inserted in the oscillator.

For many applications that require tunable sources, solid-state systems based on optical parametric oscillators (OPOs) represent the future. Unfortunately, until quite recently, OPOs have offered more promise than performance. Issues such as spectral stability and the high threshold of a narrow-linewidth oscillator have challenged many manufacturers. For reliable narrow-linewidth OPO operation, the pump laser must also meet certain special requirements, such as good mode quality, although this need has been reduced substantially at Lambda Physik (Göttingen, Germany). Specifically, novel reimaging pump-laser optics eliminate problems caused by mid-field diffraction and beam-pointing instabilities.

Given such limitations, current users of pulsed tunable sources often prefer a hybrid system that combines a narrow-linewidth dye oscillator with an optical-parametric-power-oscillator (OPPO) amplifier stage that incorporates the reimaging pump optics.

Even though an OPO provides easy access to narrow-linewidth infrared (IR) wavelengths (up to 2.5 µm or longer), a dye laser still has advantages. In nonlinear conversion processes, for example, such as harmonic generation or frequency mixing, dye lasers are efficient providers of output from 189 nm to the near-IR. In fact, dye lasers--standard tools in spectroscopic applications for many years--still offer the simplest and most economical route to tunable narrow-linewidth performance for many end users.

Imaging spectroscopy

Tunable dye lasers are excellent sources for atomic and molecular spectroscopy because the narrow-linewidth output of the laser allows discrimination between closely spaced spectral features. With smaller molecules, the narrow linewidth permits probing of individual rotational-vibrational quantum states.

Most recently, imaging spectroscopy researchers have combined charge-coupled-device (CCD) based imaging systems with narrow-linewidth lasers. Techniques such as laser-induced fluorescence (LIF) spectroscopy and Raman spectroscopy can determine which chemical species are present as well as their quantum-state distribution or temperature. The addition of two-dimensional (2-D) and three-dimensional imaging allows visualization of the spatial distribution of the species, as well as profiling of parameters such as temperature and pressure. Rayleigh scattering and Mie scattering also can be used for flow visualization, velocity measurements, and monitoring condensation rates. In addition, use of pulsed lasers and fast-gated cameras allows real-time measurements to be made on dynamic systems.

Imaging spectroscopy, or laser flash photography, is now being used for applications ranging from probing calcium-ion metabolic activity in living cells to studying the details of diamond-film deposition. End users in many of these fields want simple and reliable light sources for their investigations, hence their interest in excimer lasers and pulsed dye lasers. Many industrial users want a turnkey solution tailored to their specific needs. This was the stimulus for the formation of LaVision 2D-Messtechnik (Göttingen, Germany), a company that provides user-specific integrated systems for applications such as combustion diagnostics, plasma analysis, materials characterization, and life sciences.

Several significant measurements can be made using laser flash photography with fixed-frequency or tunable excimer lasers (some excimer lasers can be tuned over a narrow wavelength region with an internal diffraction grating). If a user needs a widely tunable source as part of a turnkey system, however, they usually specify a dye laser or dye laser/ OPPO combination because of its simplicity and proven performance.

Combustion diagnostics

Imaging spectroscopy can probe all types of combustion from simple domestic furnaces to sophisticated jet engines. Automotive-engine manufacturers are particularly interested in the technique because of ever-increasing pressure to produce more-efficient, nonpolluting engines. Thus, nearly every automotive manufacturer in the Far East is currently using combustion diagnostics technology as a matter of course.

Technical institutions are also performing research on internal-combustion engines. Scientists at the Institut für Technische Verbrennung (University of Stuttgart, Germany) use pulsed dye lasers to investigate engine knocking. In an experiment detecting LIF of formaldehyde, the pulsed output beam of a dye laser (Lambda Physik FL 3002) operating with BMQ dye (335-375 nm) was transformed into a wide ribbon, or sheet, of light so that a large area was illuminated simultaneously for multiplex 2-D detection. When the sheet of light enters the side of the engine cylinder, its dimensions are 50 mm ¥ 60 µm. A quartz window at the head of the cylinder allows the resulting sheet of fluorescence to be captured by an intensified CCD camera for quantitative image analysis.

For perfect combustion, a flame should spread smoothly and uniformly from the ignition point (that is, the spark plug). Often, as unburned gas is compressed by the advancing flame, hot spots are created that spontaneously and violently combust, which causes knocking--a sudden pressure surge in the cylinder. The goal of the Stuttgart group is to study these hot spots in detail. Formaldehyde is an intermediate species formed during internal combustion that subsequently disappears as combustion proceeds to its end point, making it an ideal species to probe this process.

Furthermore, the fluorescent behavior of for maldehyde is well understood, so it can be used to map the flame (active combustion) within the cylinder. In these experiments, the laser probed a single rotational bandhead in the 410 vibronic band of the ~A1A2 ¨ ~X 1A2.

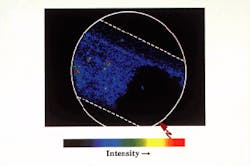

In a typical set of experiments, a series of 2-D LIF images are captured at different times during successive ignition cycles using a mixture of 90% n-heptane and 10% octane isomers (see Fig. 1). During a cycle, the flame front spreads away from the spark plug but does not proceed uniformly to the cylinder wall. Instead, auto-ignition occurs at several spots consuming the end gases. This auto-ignition correlates well with the knocking pressure surge in the cylinder measured by a pressure transducer.

Having confirmed that multiple points of auto-ignition causes knocking, the Stuttgart group is planning new experiments to investigate the phenomenon in further detail. The experiments will include double-pulse experiments to probe single auto-ignition events in real time, as well as two-color experiments to monitor both formaldehyde and the hydroxyl (OH) ion.

Other combustion measurements

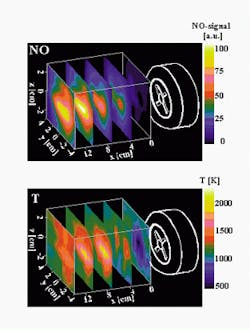

In addition to automotive engines, domestic oil-burning furnaces are also sources of unwanted nitrous oxide (NOX) emissions. The goal is to reduce such emissions without compromising efficiency. A successful study was recently completed by Andreas Luczak and coworkers at the Laser Laboratory in Göttingen, Germany. They investigated a 30-kW domestic spray-flame oil-burning furnace with a laser diagnostic system from LaVision based on a 248-nm tunable excimer laser. Both LIF and Raman imaging were used to profile the NO and OH majority species and temperature distributions in the test furnace. The data clearly showed that most NO was produced in a small area in the hottest part of the flame, as expected from the so-called Zeldovich mechanism.

An accepted method of lowering flame temperature is to recirculate exhaust gas back through the burner, so Luczak`s group mixed exhaust gas into the fuel spray. Mapping with LIF showed that only a small fraction of this gas reached the hot region of the flame. Achieving significant NO reduction would, therefore, require a large amount of recycled exhaust leading to lowered furnace efficiency and problems due to flame instabilities.

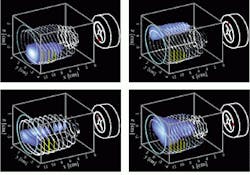

The group then tried injecting the exhaust gas at separate locations in the furnace. They seeded this gas with a known fraction of NO so that it could be accurately followed by LIF (see Fig. 2). A setup was devised to efficiently deliver high concentrations of exhaust gas into the hottest region of the flame. In this configuration, a recirculation rate of only 3% yielded a 50% reduction in NOX emissions with no reduction in furnace efficiency.

Combustion research is just one example of how imaging spectroscopy has made a successful transition from a pure research tool to a powerful real-world diagnostic tool. Our experience in such applications indicates that the availability of turnkey systems based on proven technology, including the excimer laser and pulsed dye laser, has been crucial to this rapid and varied growth. o

Tunable lasers and high-performance imaging correlate nitrous oxide (NO) and temperature distribution (T) within the spray flame of a domestic heating furnace. Most NO is produced in the hottest part of the flame. The white object sketched on the right of both images is the fuel/air mixing device. Translating the laser beam allows full 3-D images to be obtained.

FIGURE 1. Formaldehyde fluorescence intensity shows flame fronts at two different stages of cylinder firing. At 2.5 ms after ignition (left) the flame front spreads away from the spark plug (marked by the red arrow). After 5 ms the flame front is seen not to proceed uniformly to the cylinder wall (right). Instead, auto-ignition (knocking) occurs at several spots consuming the end gases, as evidenced by the dark areas. The white dotted lines define the limits of the laser-induced fluorescence excitation sheet.

FIGURE 2. Imaging spectroscopy enables researchers to inject recirculated exhaust-gas flow into the spray flame of a domestic furnace at different locations (indicated by the red dot). Of the locations tried, four are shown here, marked by a red dot in each case. The optimum position is found to be that at the bottom left. The white circles outline the active flame perimeter, as measured by the earlier OH data.