Laser manufacturers target commercial markets

Laser manufacturers target commercial markets

Compact size, high reliability, and excellent power-conversion efficiency make diode-pumped solid-state lasers useful for OEM and industrial applications.

Mark Gitin and Colin Seaton

Economic factors control the acceptance of laser technology in most original equipment manufacturer (OEM) and commercial applications. For these markets to expand, lasers must become more compact, efficient, and reliable. Of available technologies, semiconductor lasers and diode-pumped solid-state (DPSS) lasers offer the most potential for increased commercial acceptance. Thus, these technologies are the focus of intense development efforts by laser manufacturers. Recent developments in DPSS laser technology are likely to impact some commercial applications, namely underwater imaging, semiconductor inspection, and nondestructive testing.

Ring laser design

Until recently, DPSS lasers have delivered only limited output power. Past attempts at increasing output power were based on designs that obviate some of the significant benefits of this technology. At Coherent, we have designed a compact ring resonator that obtains high output power with low noise, electrical efficiency, simplicity, and reliability. The Verdi DPSS laser is the first to deliver high power while maintaining these advantages.

A neodymium-based DPSS laser generates near-infrared output (at around 1 µm) from a Nd:YAG, Nd:YLF, or Nd:YVO4 crystal. This fundamental output is often frequency-doubled to produce a 532-nm green beam. In a ring resonator, pump light from two 808-nm laser diode bars is delivered to the laser head through fiberoptic cables and imaged onto both ends of a Nd:YVO4 crystal with lenses (see Fig. 1). A lithium triborate (LBO) crystal converts the 1064-nm fundamental lasing wavelength to 532 nm.

The combination of a nonreciprocal Faraday polarization rotator and a crystalline quartz reciprocal polarization rotator positioned at Brewster`s angle creates greater loss for light propagating in one direction than in the other; this produces unidirectional operation in the cavity. A birefringent filter reinforces the natural tendency of this design to operate with single-frequency output. Finally, a series of three mirrors and an output coupler arranged in a folded pattern define a cavity of minimum physical size.

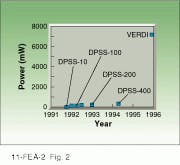

Coherent diode-pumped lasers have been based on a planar ring configuration for several years. The most recent design effort has been focused on scaling up the output of these lasers (for example, in the Compass series) to service higher-power applications, while maintaining a small overall package. Advances in laser diode technology in the past year have produced dramatic increases in output power (see Fig. 2). The Verdi generates more than 5 W of single-frequency green output.

Ring configuration advantages

High efficiency is a hallmark of DPSS lasers; the Verdi ring resonator facilitates robust, single-frequency operation, thereby eliminating the chaotic "green-noise" behavior associated with the frequency-doubling of multilongitudinal mode lasers. Designs that use many longitudinal modes to minimize the green noise problem require long linear cavities; however, this does not eliminate the problem and requires either a physically larger laser, or a resonator with several fold mirrors, which may therefore be sensitive to vibration and misalignment.

The high-gain, low-loss Verdi cavity is capable of generating several watts of visible power from the minimum amount of pump power. This efficiency allows the diodes to be derated, thus extending their lifetime; it also translates directly into higher wall-plug-to-output conversion, thus lowering power consumption.

Both laser durability and reliability are significant concerns to OEM users, because failures in the field can mean expensive product returns or on-site service calls. On the manufacturing floor, a laser failure can result in costly production downtime. The ring-cavity design of the Verdi laser is less likely to become misaligned than a longer cavity. The Verdi head is so stable that no user adjustments of the cavity optics are provided.

Placing the pump lasers and their cooling apparatus in a remote power supply and delivering their light to the head through fiberoptics in the umbilical reduces package size. In addition, the laser head does not require active cooling, provided it is mounted on an adequate heat sink, giving an advantage over air-cooled lasers that need a fan, as well as open space in the head to permit adequate cooling air flow.

Underwater imaging

The factors of laser size, reliability, and efficiency are critical in underwater imaging. An example of such a system is the SM2000 Laser Line Scan System manufactured by the Oceanic Systems Unit of Northrop Grumman Corp. (Annapolis, MD). This product provides high-resolution video images of the seafloor. It is typically used in underwater inspection of structures such as dams and pipelines, as well as in search-and-salvage operations. The device was recently used by the US Navy to aid in the investigation of the crash of TWA Flight 800 off Long Island, NY (see Laser Focus World, Sept. 1996, p. 13).

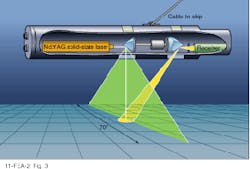

The SM2000 consists of a small submersible structure that is pulled through the water by a cable (see Fig. 3). A DPSS laser beam is rastered perpendicular to the direction of motion by polygon mirrors; scanning in the other direction is provided by the motion of the device itself. Returned light is detected by a photomultiplier tube (PMT) receiver; electronics transform the PMT output into a video signal.

In this application, the laser is being used as a spot illumination source. Although a system based on a standard video camera with a floodlamp or strobe would be simpler to construct, the narrow spot and high brightness of the laser minimize the resulting backscatter to significantly increase the operational range over such systems.

The first consideration in selecting a laser source for this purpose is that its output wavelength must fall within the 450-550-nm transmission band of seawater. The second-harmonic output of a DPSS laser at 532 nm meets this requirement. Space and electrical power are both at a premium aboard a boat; size, weight, and power consumption are all considerations that favor the use of a DPSS laser over other technologies. Laser reliability is also a benefit because of the difficulty in obtaining service when the unit is out in the field. Currently, the SM2000 uses a 0.4-W DPSS laser; in the future, upgrading to the 5-W Verdi laser will significantly increase the range of the system.

Semiconductor inspection

Contaminant particle identification in semiconductor wafer manufacturing is another application in which DPSS lasers can prove advantageous. Typically, the beam laser is scanned over the surface of the wafer under test, and scattered light is collected. The intensity and angular spread of the scattered light provides information about the size and shape of any particulates present.

Laser power and wavelength are both important in this application. Shorter wavelengths allow smaller focused spots, which directly determine the limiting spatial resolution of the system. Higher output power provides greater sensitivity and allows faster scanning, which increases throughput.

Argon-ion lasers were initially used in many semiconductor inspection systems; these are now being supplanted by DPSS lasers, which are smaller and more reliable. Furthermore, lower power consumption and maintenance requirements of a DPSS laser result in lower operating costs than even air-cooled argon-ion lasers. These factors should be sufficient to offset the higher initial purchase price of a DPSS laser over even a short period of operation. Finally, reliability is a factor in an environment in which production downtime is extremely expensive.

Nondestructive testing

Nondestructive testing applications, especially those involving holography or interferometry, often demand excellent laser performance in addition to the other characteristics previously discussed. Electronic speckle pattern interferometry (ESPI) shearography of automobile tires provides an interesting example of nondestructive testing in an industrial setting.

In an ESPI shearography system manufactured by Steinbichler Optotechnik (Neubeuern, Germany), laser output is split into two beams; the first beam is expanded to illuminate the object under test, then subsequently imaged onto a charge-coupled-device (CCD) camera. The second (reference) beam is expanded and then recombined with the object beam before reaching the CCD camera, causing the image to contain a fringe pattern, which essentially constitutes a topographical map of the object. Such a configuration is similar to that of holography, except, in this case, a very small angle is used between the object and reference beams, resulting in a relatively large fringe spacing (ª 20 lines/mm), as opposed to the very small fringe spacing (ª 1000 lines/mm) produced by the large angle between object and reference beams in most film-based holography set-ups.

In actual operation, a tire is placed in a vacuum chamber, and an interferometric image is acquired (see photo on p. 153). Next, air pressure in the chamber is slightly reduced, causing any faults in the tire, which are usually related to air pockets, to manifest themselves as a physical distortion. A second interferometric image is obtained, and the two are electronically subtracted. The result is an image containing a fringe pattern that represents the first derivative of any physical changes that occurred in the tire between the two original images. An advantage of this technique over traditional holographic interferometry is that results can be obtained quickly because no film processing is required. Also, the mathematical process used to create the final image is not influenced by rigid body motion, making the technique insensitive to vibration.

In order to produce interference fringes over the physical distance of a few meters, good coherence length is required. This requirement means the laser must operate in a single longitudinal mode. Furthermore, excellent transverse mode structure is also required, as this directly affects fringe contrast. Because the tires are black, high laser brightness (output power) is desirable to minimize exposure times and increase overall throughput. Finally, the adverse environment of a factory calls for a laser that is insensitive to mechanical vibration as well as to variations in input electrical power and cooling water.

DPSS lasers making impact

In the past, argon-ion lasers were the only high-power, CW single-mode source available for this application. Now, single-mode DPSS lasers can make an impact in this field. High-output-power lasers, such as the Coherent Verdi, can be used on larger objects and will increase the throughput of existing systems.

The first DPSS lasers to appear on the market were low-power devices, which limited their applicability. Now, ring resonator design allows the output power of DPSS lasers to be scaled up without sacrificing the lasers` primary advantages, thus delivering on the promise of DPSS technology. As advances built around this technology continue, the market for DPSS lasers should continue to expand. o

Diode-pumped solid-state laser illuminates tire in electronic speckle pattern interferometry shearography apparatus to provide nondestructive testing data.

FIGURE 1. Ring resonator configuration in diode-pumped Verdi laser ensures single-frequency high-power output in compact package.

FIGURE 2. Improvements in 808-nm pump lasers have resulted in power increases from single-frequency, green-emitting diode-pumped solid-state lasers over the past few years.

FIGURE 3. In underwater imaging system developed by Northro¥Grumman, frequency-doubled DPSS laser system illuminates through seawater to produce video images of submerged items.

Mark Gitin is with the Commercial Business Unit and Colin Seaton is with the Scientific Business Unit of Coherent Inc., Laser Group, 5100 Patrick Henry Dr., Santa Clara, CA 95054.