Sealed CO2 lasers enter the high-power arena

GREG DUNHAM

Since their launch into the industrial marketplace almost 15 years ago, sealed carbon dioxide (CO2) gas lasers have created many new markets for themselves in applications requiring low-cost, low-power sources of energy. With output powers of 10 to 240 W, thousands of sealed CO2 lasers are used for engraving, marking, and cutting materials such as plastics, wood, ceramics, and even thin metals. Sealed lasers offer industrial users the benefits of small size and rugged construction combined with operating lifetimes in excess of 35,000 hours. They can be mounted on robotic arms or moving-gantry systems, are simple to integrate, and require minimal maintenance.

Flowing-gas CO2 lasers offer output powers from 500 W to multikilowatt levels and, on a dollars-per-watt basis, are considerably less costly than their smaller radio-frequency (RF) excited relatives. These lasers have been the industrial workhorses for more than two decades and helped pioneer the use of lasers in the aerospace and automotive industries. However, their size, gas consumption, and ongoing maintenance requirements have always represented problems for many users.

Among applications for high-power sealed lasers, dieboard cutting is an area where such lasers excel. Dieboard is multilayer laminated wood approximately 0.5 to 1 in. thick, usually consisting of five to 12 layers or more that are glued together. This laminate is then through-cut to a specific pattern using the laser. Sharp metal blades are driven into the slots forming the die. The finished die is used for stamp-cutting patterns in various materials such as gasket stock, paper, and sheet plastic. In this way, dies of any shape can be readily manufactured to cut different materials quickly and at high speed.

The high mode quality of sealed lasers combined with their excellent power stability results in through-cuts of high quality that exhibit excellent parallelism of the walls through the cut depth, as well as consistent cut width. These key aspects ensure the correct fit of the blades in the slots. Additionally, sealed lasers are ideal for systems integration, having a small footprint, no requirement for laser gases, and a robust design. Other applications include cutting and welding of sheet metal and high-speed processing of plastics and a host of other organic materials.

Sealed-tube technology

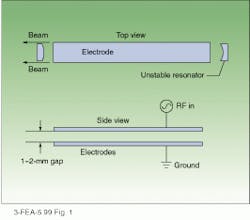

The first company to break the half-kilowatt barrier with a sealed CO2 laser was Coherent (Santa Clara, CA) in 1998. Using a "slab"-waveguide design, Coherent specifies a minimum output power of 500 W (see Fig. 1).The choice of 81.36 MHz as a drive frequency does mean that achieving Federal Communications Commission (FCC) and European Community (CE) compliance requires careful shielding of the laser. However, the high gas pressure and small electrode gap are capable of a power extraction figure of 1 W/cm2 of electrode area and an optical risetime in the region of 50 µs. Although this cavity produces a lower mode quality due to the high aspect ratio of the output beam, this is correctable with additional optics inside the laser housing. Coherent’s half-kilowatt laser has an output beam with quality of M2 = 1.5 from a laser head measuring only 47 × 11 × 9.5 in. and weighing 135 lb.

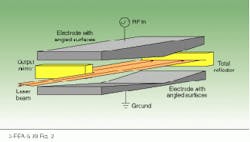

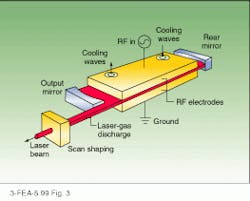

Due for launch in mid-1999, the Synrad (Mukilteo, WA) 600-W sealed CO2 laser uses a split-wave hybrid resonator design (see Fig. 2). The angled electrode structure selects for the lowest-order free-space mode oscillation, which translates to a typical M2 value of 1.2 for the output beam. In addition, the 5-mm interelectrode gap allows assembly tolerances to be relaxed and does away with the requirement for the electrodes to have a polished surface. This simplifies the manufacturing process and re duces cost of manufacture. The low er radio frequency of 40.68 MHz is an FCC industrial, scientific, and medical standard and makes compliance with FCC and CE RF emissions regulations easier. Disadvantages of this design are slower optical risetimes (about 100 µs) and lower power ex traction, typically around 0.6 W/cm2.RF technology

Although it is clear that sealed CO2 tube technology has already reached a point at which the performance of the laser is comparable to or better than an equivalent-power flowing-gas laser, a major obstacle still remains—price. Currently, a 250-W sealed CO2 laser is similar in price to a 500-W flowing-gas laser because of the cost of RF power.

Carbon dioxide lasers typically operate at around 10% to 15% efficiency (the ratio of optical output power to input electrical power). Most flowing-gas lasers use high-voltage direct-current (DC) supplies, which, at a dollar per watt, represent relatively inexpensive and mature sources of power. However, disadvantages include difficulty in pulsing DC-excited lasers and physical dangers associated with high-voltage dc power. Sealed lasers use RF electrical power, more difficult to generate and therefore more costly on a dollars-per-watt basis—RF power is, on average, twice as expensive as DC power.

Radio-frequency power is typically generated using either vacuum tubes or solid-state devices. Vacuum tubes, although cheaper than transistors and tolerant of a wide range of load impedance, suffer from poor lifetimes (less than 10,000 hours) and large size. High-power transistors offer a compact and reliable source of RF power and operate well under a range of industrial environments.

Although the cost of solid-state RF power has fallen over the past few years, it is still sufficiently expensive that, for a 1-KW laser, the cost of the RF power alone would exceed $30,000.

Future of sealed CO2 technology

The benefits of sealed CO2 technology at power levels above 500 W are exactly the same benefits that have led to their success at lower power levels. A sealed CO2 laser can be considered a “light bulb,” rugged and reliable, with a continuous, maintenance-free operating lifetime in excess of 35,000 hours.

Sealed lasers are compact and can easily be mounted onto production lines, movable gantries and robot arms (see photo at top of this page). Applications include processing of ceramic and metallic materials, high-speed cutting of paper, or welding sheet plastics. They are used to cut out air bags for the automotive industry, in direct-to-mold laser sintering, and for large-area dieboard cutting.

However, the real future for sealed CO2 lasers in the high-power industrial market will depend strongly on the development of less-expensive RF power. Both Coherent and Synrad have laser-cavity designs that are easily scalable to produce 1 kW or more—commercially viable provided that the cost per watt for RF power could be reduced substantially.

One of the most promising indications that this might be possible is the development of high-voltage RF-power metal-oxide-semiconductor field-effect transistors (MOSFETs). These are low-cost epoxy-packaged N-channel enhancement-mode MOSFET parts designed to operate at voltages up to 300 Vdc and at frequencies to 100 MHz. Typical devices provide almost twice the RF output-power capacity of the ubiquitous half-inch flange MOSFETs at around half the cost.

Lower-cost RF power is an obvious advantage of the new transistors, but an additional benefit comes in terms of reduced currents, both dc and RF. The size and cost of almost all the electrical components in the laser are directly related to their current-handling capacity. Conduction losses in these components are related to the square of the current, so by increasing the operating voltage from 30 to 120 Vdc, for instance, a fourfold reduction in current is gained, leading to a sixteenfold reduction in losses for the same power level.

These benefits could lead to startling reductions in the size, cost, and complexity of RF final stages and the associated ac/dc converters. Cooled by laser exhaust water, RF systems neatly packed inside the laser head become possible, even at the kilowatt optical level and beyond. Long, stiff RF cables and external RF generators may soon give way to self-contained laser heads with only thin, flexible dc or even ac power cables. A 1-kW laser lightbulb may not be far away.

Greg Dunham is research-and-development laboratory coordinator at Synrad Inc., 6500 Harbour Heights Pkwy., Mukilteo, WA 98275; [email protected].