Ultrafast Lasers: Picosecond laser cuts through fog

More than a decade ago, a group at the Université Claude Bernard Lyon (Villeurbanne, France) showed in a laboratory that when light filaments created by ultrafast laser pulses were passed through fog, they did not attenuate as much as expected because when the filament itself was blocked, it drew energy back from the surrounding "photon bath," replenishing the energy in the filament.1

Now, researchers from Université de Genève (Geneva, Switzerland) and Trumpf Scientific Lasers (Munich, Germany) are using light filaments created by a picosecond laser, again in a laboratory, to clear a path through fog, potentially allowing other types of laser beams to pass unimpeded through fog and clouds.2 Potential applications include free-space communications, remote sensing, or, more speculatively, altering local weather.

Shockwave clears fog droplets

In the experimental setup, light from a Trumpf Dira thin-disk laser producing 100 mJ pulses with a 1.3 ps duration and a 1030 nm wavelength was slightly focused into a 40-cm-long fog chamber. The laser's repetition rate was varied between 100 and 1000 Hz, for an average power of 10 to 100 W.

The fog exhaust vent blew onto the laser beam, providing in total an approximate 50-cm-long fog path for the beam. The fog itself consisted of droplets with a 5 μm average size, but at a concentration about 100 times higher than that of a typical outdoor fog.

Three to four filaments were produced that carried about 15% of the energy of the total beam (the rest of the light provided the photon bath). The beam was imaged onto a screen, which was in turn imaged by a CCD camera through an optical filter that completely blocked the shorter-wavelength continuum produced by nonlinear optical interactions in the air, but only partially blocked the fundamental wavelength.

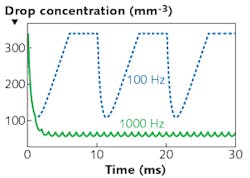

Beam transmission through the fog ranged from 0.1% at a 100 Hz repetition rate to 32% at a 1000 Hz rate. At higher transmission, the entire beam path, not just the paths of the filaments themselves, was cleared of fog. The researchers hypothesize that the energy deposition in the droplets in the filaments creates a reduced-pressure (0.5 atm) channel and a resulting shockwave in the air that ejects the droplets from both the filaments and the larger beam path.

Although the pulses in the 100 Hz beam can clear droplets from the beam path to a certain extent, the time between pulses is long enough that the droplets in the beam are replenished between pulses (see figure). However, the 1000 Hz beam results in a steady state in which the droplets do not have time between pulses to re-enter the beam path.

REFERENCES

1. F. Courvoisier et al., Appl. Phys. Lett., 83, 2, 213 (Jul. 14, 2003).

2. L. de la Cruz et al., arXiv:1612.08276v1 [physics.optics] (Dec. 25, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.