Solid-state lasers pack more punch into a pulse

Laser light was first produced nearly 40 years ago with a ruby crystal. Since then, researchers have developed a wide range of laser materials and devices, but solid-state lasers, like the original ruby ones, have retained an important role. Such lasers, now using neodymium, erbium, and other rare-earth elements, as well as metals such as chromium, are capable of producing extremely high peak powers in very short pulses. This has made them particularly useful in many research applications, most notably controlled thermonuclear fusion, for which the US Department of Energy is constructing the world’s largest lasers.

Principles of operation

While semiconductor or diode lasers are based on materials in the solid state, the term "solid-state laser" has come to exclude such lasers. Instead, it applies to lasers using nonconducting solid materials that are pumped by an external light source (in some cases the light source is a diode laser). The laser material in such lasers consists of an active or light-emitting species such as a dopant in a glass or crystalline matrix. Typically the light-emitting elements are about 1% of the atoms of the matrix.

The light-emitting elements are selected for a number of characteristics. First, they have to absorb energy over a range of wavelengths emitted by a suitable pump source, either a flashlamp or diode laser. Second, they have to be able to have a metastable state at which excited atoms can remain long enough for a laser pulse to develop. And third, they must be able to emit in a useful wavelength range that is not absorbed by the surrounding matrix.

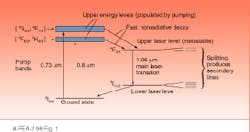

For the most part, solid-state light emitters have a four-energy-level structure. From the ground state the atoms are pumped into excited states corresponding to the absorption bands. They then rapidly decay to the upper laser level, a metastable state. When stimulated to emit a photon, the atom drops into the lower laser level, another metastable state, emitting the photon into the laser beam. The atom then decays to the ground state. This four-level structure ensures that atoms at the ground state will not be able to absorb the laser light wavelength.

Ruby is an exception to this rule, having only three levels, with the atoms dropping directly from the metastable state to the ground level when stimulated to emit a photon. Ruby lasers consist of a synthetic aluminum oxide crystal (the same material as natural sapphire), doped with 0.01%-0.5% chromium. To avoid excess absorption, nearly all the chromium atoms in the ruby rod must be pumped to an excited state, making the ruby laser relatively inefficient.

By far, the most widely used solid-state light-emitting material is neodymium, which has a four-level structure and emits at 1060 nm, in the near-IR (see Fig. 1). The host or inactive material for neodymium is normally yttrium aluminum garnet (YAG), although glasses are also commonly used. In both cases, the requirements for the host material are transparency to both the pumping and laser wavelengths and relatively good thermal conductivity, as the vast majority of the energy from the pump source ends up heating the host material.Unfortunately, YAG is hard to grow, and only small rods, typically less than 1 cm in diameter and 10 cm long, can be cut form the crystal boules. This limits the energy-storage capacity of Nd:YAG rods to about 0.5 J. However, such laser rods can be pulsed repeatedly at more than 1 kHz, so average powers can exceed 1 kW, although most lasers function at far lower levels. Peak power in a Q-switched pulse of 10 ns can exceed 100 MW, and far higher powers are possible with shorter pulses.

Neodymium-doped glass lasers have poorer thermal conductivity than Nd:YAG lasers, so they cannot be pulsed rapidly because this would lead to heat build-up. However, glass rods and slabs can be grown to large sizes, making possible individual pulses

with very high energy. In addition, Nd:glass lasers emit broader-bandwidth light, making possible still shorter Q-switched pulses than are possible with Nd:YAG lasers. The emitted wavelength varies slightly according to the glass used: 1062 nm for silicate glass, 1054 nm for phosphate glass, and 1080 nm for fused silica.

Less commonly used than glass or YAG is yttrium lithium fluoride (YLF). It stores more energy than YAG, and it changes its refractive index less with heating, although its thermal conductivity is lower. Because the system is birefringent, it produces two wavelengths, 1047 and 1053 nm, each with a different polarization.

A second major type of solid-state laser uses erbium, which lases at 1550 nm, exactly in the wavelength range most useful for fiberoptic communications. Erbium-based optical amplifiers have become central to the newest generation of fiberoptic systems, allowing the regeneration of signals without requiring electronic repeaters. In such amplifiers, a loop of fiber doped with erbium is pumped by a semiconductor laser at 980 or 1480 nm. In addition, bulk erbium lasers are used in applications in which their long wavelength, which is not harmful to the human eye, provides a safety margin, as in military rangefinders used in war games.

Another rare-earth element, holmium, is used for lasers at 2100 nm, also in a YAG or YLF crystal. Such lasers have as yet limited applications, mainly in medicine.

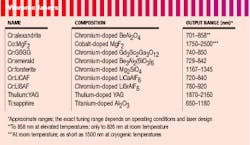

The third type of solid-state laser, the vibronic laser, provides an output tunable over a range of wavelengths. While in ruby, neodymium, and erbium lasers the upper and lower laser levels are single states, in vibronic lasers the lower level is a band, representing the vibration sublevels of a single electronic energy state. These vibrational substrates are caused by the linkage of the electronic energy level to vibrations of the crystalline lattice. As a result, vibronic lasers can emit over a range that is 䔸% from a central wavelength. By adjusting the optical cavity length, any laser wavelength within this band can be selected, producing a tunable output.Laser structure

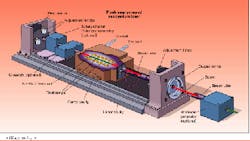

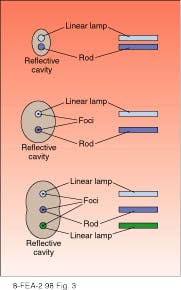

In addition to the rod or slab of laser material, a solid-state laser consists of a pumping light source and pump cavity, a resonant cavity, and, in some cases, external amplifiers or harmonic generators (see Fig. 2). If the pump source is a flashlamp or tungsten arc lamp, the lamp may simply be placed next to the rod, or lamps may be placed at the foci of elliptical mirrors, with the laser rods at the other focus (see Fig. 3). For diode-laser-pumped lasers, a pump laser can illuminate the solid-state laser rod from the end, or in higher-power designs, an array of diode lasers can pump the rod from the side.Because flashlamps emit over a broad range of wavelengths, only a small fraction of which are useful for pumping, such lasers tend to have low overall efficiency, converting about 0.1%-1.0% of electrical energy into laser light. In contrast, diode-pumped solid-state lasers (DPSSLs) can have high overall efficiency, because the diode lasers are themselves highly efficient, and they can pump laser energy directly into the wavelengths needed. Thus, overall efficiencies of DPSSLs are at least ten times higher than for flashlamp-pumped lasers, around 10%, so high-power industrial lasers can be made compact and truly portable—essentially hand-held. The inherent advantages of solid-state lasers are all retained: very high beam quality, nearly diffraction-limited beam divergence, high beam-pointing and amplitude stability, high peak power, and repetitive pulsed-mode operation. [Such diode-pumped solid-state lasers will be the topic of a future Back to Basics article -Ed.]

Like other lasers, solid-state lasers require a resonant cavity to produce the laser beam. The resonator has to compensate for thermal lensing caused by the uneven heating of the laser rod and usually uses a curved mirror or a combination of mirrors and lenses to refocus the beam, producing narrow divergence. While the use of a rod of laser material is suitable for most medium-power applications, for higher powers, a slab of material provides a larger laser volume. The beam bounces in a zig-zag fashion between the upper and lower surfaces of the slab, being refracted to the axis of the resonator cavity by the slanted ends of the slab. Such slab lasers can typically achieve average powers of 2 kW or more.

Once the laser beam has been produced, it is often modified in a number of ways. To achieve higher energy per pulse, external amplifiers can add to the beam. Such amplifiers are pumped slabs or disks of laser material, but without the resonant cavity of the initial laser. As the beam passes through them, the energy stored in the amplifier is dumped into the pulse. Multiple stages of amplification provide still higher-power operation.

As with other pulsed lasers, Q-switching can also increase the peak power by reducing the duration of the pulse. In Q-switching, one mirror in the cavity is blocked by an absorptive medium. Because photons cannot bounce back and forth to build up the laser beam, a population inversion much larger than needed for lasing can be built up. When the absorptive medium is suddenly changed to a transmissive one, exposing the mirror, an intense laser pulse rapidly drains the higher energy level in a time much shorter than a normal pulse. An electro-optic or acousto-optic switch can rapidly change the blocking medium from absorptive to transmissive and back again.

The very high peak powers of solid-state lasers make them especially suitable for the production of higher-frequency wavelengths by second-, third-, and fourth-harmonic generation in nonlinear materials. Harmonic generation occurs because in some materials the optical output depends not only on the input amplitude but also on the input amplitude squared, cubed, and so on. These higher-order terms can produce output frequencies double, triple, or quadruple the input frequency. Such harmonic generation is strongly dependent on power levels and so is far more efficient at high peak power. For neodymium lasers, frequency-doubling or second-harmonic generation produces green light at 520 nm, tripling UV radiation at 351 nm, and quadrupling UV at 263 nm.

Tunability and higher power

While solid-state lasers are a mature technology, research is continuing to expand their capabilities, especially in the areas of tunability and higher peak powers. One of the goals of this research is the development of tunable UV solid-state lasers. Scientists at both Spectra Physics Lasers (Mountain View, CA) and the USAF Wright Laboratory (Wright Paterson AFB, OH) have been working on cerium-based lasers in a LiCAF, LiSAF, or SrAlF5 crystal.

All such lasers emit laser light over a band from 280 or 290 nm to 315 nm, which can be tuned by inserting a prism or other dispersive element into the resonant cavity. These lasers are pumped by the fourth-harmonic output of a neodymium laser, so overall efficiency is low, but output is sufficient for the environmental-monitoring applications in which UV tunability is needed, such as spectroscopic studies of atmosphere pollutants. [Tunable lasers will be further examined in a future Back to Basics article -Ed.]

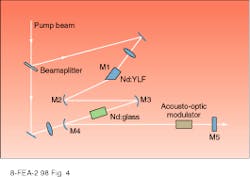

Another area of active research is the use of solid-state lasers for pulses shorter than 100 fs. Generally these ultrashort pulses are from Nd:glass lasers, because the broad linewidth (200 cm-1) of the glass lasers makes short-pulse formation easier. But modelocking, the best way to archive very short pulses, requires good phase coherence, which is better achieved by Nd:YAG. Li Yan and Bo Guo of the University of Maryland (Baltimore, MD) are making progress in combining the strengths of both crystals by using an optical cavity containing both a Nd:glass and Nd:YAG laser, producing a hybrid device with both good phase coherence and short pulses (see Fig. 4).In industry, Nd:YAG lasers are used for drilling, resistor trimming, marking, and mask and memory repair, where a small focal spot is essential. The short pulse length has made such lasers ideal for medical applications as well, where the requirement is delivering the energy swiftly before adjacent tissues can be heated and damaged. The neodymium wavelength of 1054 nm penetrates tissue and is used for cutting, while the longer Er:YAG wavelength of 2940 nm is suitable for treating upper layers of the skin. Nd:YAG lasers have been used for ophthalmic surgery, such as the removal of opacities or for retinal reattachment. Ruby lasers have long been used in the removal of tattoos, and erbium lasers have shown promise as a substitute for the dentist`s drill.

The ability to store large amounts of energy and to deliver it in very short pulses makes the Nd:glass laser ideally suited to scaling to extremely large peak powers. This has motivated the construction of huge laser-fusion facilities at Lawrence Livermore National Laboratory (LLNL; Livermore, CA) and elsewhere. These facilities have up to now used arrays of Nd:glass lasers pumped by flashlamps to deliver more than 100 TW/cm2 onto a pellet of fusion fuel, causing the outer layers to blow off and implode the core. This produces high compressions and high temperatures, leading to minute fusion explosions (see photo at top of this page).

While the Department of Energy is using gigantic lasers such as Nova and the National Ignition Facility (NIF) for research, the lasers are far too slow and inefficient to lead to useful power production. Nova, for instance, pulses only once an hour—that much time is needed to dissipate the heat produced. The NIF, delivering 1.8 MJ of laser energy per pulse, will also have low efficiency. A new generation of giant laser that will be diode-laser pumped with much higher efficiency will have diode lasers operating at 55% efficiency and overall laser efficiency of 8.6%. At such levels, heat loads are dramatically decreased.

FURTHER READING

C. D. Orth et al., Nuclear Fusion 36, 75 (Jan. 1996).

H. Jelinkova et al., SPIE 2965, 140 (June 1996).

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.