Dense arrays may lead to high-resolution printers

If lasers could be stacked close enough together in a laser printer such that each was responsible for placing a dot on the paper, it would eliminate the current need for laser beam-steering with a spinning polygonal mirror. This might lead to lower-cost printers and could certainly increase printing speed. Project leader Robert Thornton, Chris Chua, and David Treat at Xerox Palo Alto Research Center (PARC; Palo Alto, CA) have developed a very dense linear array of vertical-cavity surface-emitting lasers (VCSELs). These could be used in laser printers, as well as optical signal-processing systems. For both applications, the more elements in an array, the better.

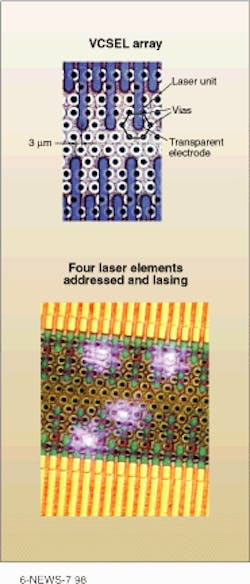

At the Conference on Lasers and Electro-Optics (CLEO; San Francisco, CA) in May, Chua presented paper CdThK6 on making independently addressable VCSEL arrays with only 3 µm from the center of one VCSEL to the center of the next. Current typical VCSEL arrays have center-to-center spacing of about 50-100 µm.

The high-density array from PARC is made possible by transparent contact technology and a planar laterally oxidized device architecture. CLEO session chair Kent Choquette of Sandia National Laboratories (Albuquerque, NM) says, "The technologies are old hat, but the ways the Xerox group is using them is pushing the envelope."

VCSEL design

"We are interested in replacing the polygon in a laser printer with an array of semiconductor lasers," explains Chua. If each dot corresponds to a laser, then a printer with 1200 dots-per-inch (dpi) resolution would require 1200 VCSELs per inch. "If you have a document 11 in. long, you need roughly 13,000 lasers," he adds. With a 3-µm pitch, "a device 4 cm long would contain more than 10,000 lasers." The advantage of having so many lasers in such a small area is that it allows for a reasonable manufacturing yield.

The devices must exhibit certain characteristics. Regular VCSEL arrays use opaque metallic top contacts that take up space between the emitting areas. For this device, however, the researchers used interdigitated transparent contacts made of indium tin oxide—the same material used for transparent contacts on active-matrix liquid-crystal displays (see figure). As with these displays, this arrangement allows individual addressing of the VCSELs.

Heat, in particular, can be a problem; with the lasers so tightly packed, heat from one device can affect the surrounding devices. Individual lasers must, therefore, work at low operating currents and high power-conversion efficiency.

Oxidation

To achieve the high efficiency, the researchers use a variation of lateral oxidation, a technique developed in 1994 at the University of Texas (Dallas, TX). By selectively oxidizing an area around the active area of the VCSEL, the light is better confined. Lateral oxidation improves the efficiency of a VCSEL by orders of magnitude, says Chua. But the standard method is difficult to manufacture. It requires etching out a mesa (containing the VCSEL) to expose the layer to be oxidized. The etching reduces the planarity of the device, which makes establishing electrical contacts more difficult. This is why no commercially available VCSELs use this technique.

Instead, the researchers used photolithography and a dry-etch method to create a uniform grid of via holes into the epitaxially grown layers. Small circular patterns are made, then etched about 3.5 µm deep. The 2-µm-diameter holes allow access to the aluminum gallium arsenide (AlGaAs) layer, which is selectively oxidized. Each VCSEL is bordered by six via holes. The AlGaAs layer is oxidized outward from each hole until a 4-µm-diameter aperture is exposed at the center. This method maintains the planarity of the device.

Operating characteristics

The device was grown by metal-organic vapor-phase epitaxy on n-type GaAs substrate. The bottom mirror has 35 pairs of silicon-doped AlGaAs distributed Bragg reflectors. The resonant cavity is a one-wave-thick separate confinement heterostructure with four strained indium aluminum gallium arsenide (InAlGaAs) quantum wells. The oxidation layer of AlGaAs is grown above the active region, and 25 pairs of magnesium-doped distributed Bragg reflectors are deposited as the top mirror of the VCSEL.

The lasers operate at a wavelength of 813 nm with threshold currents of less than 200 µA and threshold voltages of less than 3.5 V. The arrays showed low interelement thermal crosstalk, which indicates that heating effects are within acceptable boundaries for the array. The array has electrical resistance of 3 MW between adjacent array elements. Output powers for a 16-element array ranged from 270 to 340 µW.

The researchers also looked at far-field interference patterns in the outputs of the lasers. A lack of interference effects in the optical far-field of the VCSEL beams indicates that the lasers do not have coherent optical crosstalk. Furthermore, the transverse mode of any one device is not affected by the state of its neighbors.