We’ve all heard the promises of solid-state lighting: greater energy efficiency, lower maintenance costs, longer lifetimes, broader design flexibility, increased environmental friendliness, and more. We’ve also seen the timelines and roadmaps put out by the U.S. Department of Energy and the Optoelectronics Industry Development Association for the development and commercialization of this technology. But what has all the planning and research, all the industry collaboration, yielded so far in the way of commercial products and applications? Are companies that produce light-emitting diodes (LED) and developers of lighting systems moving forward with real-world installations?

In a word: yes—although white-LED lighting for general illumination is still a way off. But thanks to inroads made by color LEDs in the automotive, entertainment, and retail industries over the last 10 years, plus advances in LED technologies and packaging, white-light LEDs are being used increasingly in contained lighting situations, from elevators and nursing homes to aircraft cabins and grocery-store aisles.

Generally speaking, solid-state lighting refers to the use of high-brightness LEDs (HB LEDs) as light sources to replace conventional incandescent and fluorescent lamp technologies (organic LEDs are also being developed for lighting applications but are much further out). Driven primarily by color-LED applications such as traffic signals and decorative lighting, the market for HB LEDs has grown nearly 50% per year since 1995 and is projected to top $500 million in 2007, according to Strategies Unlimited (Mountain View, CA).

While the majority of solid-state lighting applications to date have involved colored light, white-light illumination is the “holy grail” of the LED industry. White LEDs, introduced in the late 1990s, have made tremendous progress in performance and lumen output, with efficiencies now exceeding those of incandescent lamps. As a result, white LEDs are now beginning to enter the $12 billion market for illumination—albeit initially in niche applications that can leverage the current lumens per watt in ways that create functional and cost-based advantages.

“It is important to put white light in the context of the overall LED lighting market, which is growing quite rapidly,” said Robert Steele, director, optoelectronics practice at Strategies Unlimited, a Pennwell company. “Most of the LEDs used in lighting today are still red/blue/green (RBG) LEDs for color applications, and this is paving the way for the acceptance of LEDs in general by creating awareness in the lighting and architectural communities about what LEDs are and what they can do. This is a gradual process, with white LEDs currently addressing niche applications where they make technical, design, or aesthetic sense before they begin capturing parts of the general-illumination business.”

Four decades of development

Light-emitting diodes were first developed in the 1960s but have only become intense enough for lighting in the last decade, initially for indication applications such as traffic signals and signage and, more recently, for illumination (both color and white light; see Fig. 1). The two main types of LEDs used for lighting systems are aluminum gallium indium phosphide (AlGaInP) alloys for red, orange, and yellow LEDs; and indium gallium nitride (InGaN) alloys for green, blue, and white LEDs. Slight changes in the composition of these alloys changes the color of the emitted light.

White LED light can be produced in one of several ways: additive mixing of red, green, and blue LEDs; combining a blue LED and a phosphor to down-convert the light; or combining an ultraviolet LED with several phosphors. It is generally acknowledged that the industry’s goal of 200 lumens/W for general illumination can be best achieved by combining three or more LEDs of different colors. In fact, LED lighting developers have found that by adding amber to the RGB mix, the light is more pleasing to the eye (see “The right parts,” below).

Currently, white LEDs can achieve 25 to 50 lumens/W, and the price has dropped to a point where they can be used in certain—albeit primarily contained-illumination applications. By comparison, incandescent lamps typically produce 12 to 15 lumens/W and compact fluorescent lights (CFLs) produce at least 50 lumens/W. In addition, a 75-W incandescent light bulb typically costs less than $1 and a comparable CFL costs about $5—both about $1 per thousand lumens—while current white-LED products cost more than $150 per thousand lumens. (The tradeoff, of course, is that LED lights have been found to last 35,000 hours or more compared to about 1000 hours for conventional light sources.)

While lumens per watt and cost still play a key role in determining what white-light applications are possible at this point, the most important factor for early adopters of white LEDs for lighting is whether the solution makes sense, given the physical constraints or design considerations of the installation and the needs of the end user. Some of the first such applications involve contained lighting, where the current capabilities of the technology meet and often exceed the abilities of conventional light sources.

“With LEDs, this is a chance for us to reinvent light and mix it in such a different way that the quality of light is a distinct improvement over existing sources and changes the way we illuminate things,” said Kevin Dowling, vice president of strategy and technology at Color Kinetics (Boston, MA).

For example, LEDs have been used in niche aircraft lighting applications such as “No smoking” and “Fasten seatbelt” signs for quite some time. But advances in white-LED technology have prompted aircraft manufacturers to consider LEDs for more general cabin lighting applications, such as the passenger reading light, which could reduce onboard energy consumption. Color Kinetics’ Chromacore technology is an integral part of the Digital Mood Lighting System manufactured by B/E Aerospace, a supplier of aircraft cabin interior products. The Digital Mood Lighting System generates programmable, colored effects and general-purpose cabin lighting through microprocessor-controlled LEDs. Quantas also uses LEDs to create mood lighting in its first-class cabins. More recently, Airbus has used white LEDs in its aircraft for reading lights, and engineers at the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute (RPI; Troy, NY) are working with Boeing to develop LED lighting for its newest aircraft.

Another LRC project involves the use of white LEDs in commercial display freezers. The LRC is collaborating with GE’s GELcore, Price Chopper supermarkets, and Tyler Refrigeration on this project. In 2004 the team installed a four-door freezer with a prototype LED lighting system in the frozen-food aisle at a Price Chopper supermarket in Albany, NY, and has been evaluating it in terms of performance and customer reaction.

“LEDs are not plagued with the cold temperature problems affecting fluorescent lamps, which means energy and maintenance costs can be reduced in the long run by using LEDs inside freezers,” said Nadarajah Narendran, director of research at the LRC and head of the LRC’s Solid-State Lighting Program.

In what could prove to be one of the first volume markets for white LEDs—elevator lighting—the LRC developed and evaluated a low-profile LED downlight to replace a less-efficient incandescent luminaire in an elevator. During a two-year project sponsored by the California Energy Commission’s Public Interest Energy Research Program and the Architectural Energy Corp. (Boulder, CO), LRC researchers collaborated with Otis Elevator Co. to modify the ceiling panel of an elevator, replacing the original incandescent fixtures with six prototype fixtures built with Westinghouse Lighting (Philadelphia, PA; see Fig. 2).“LEDs are an ideal light source for elevators because their rugged design can withstand the vibrations and motions of the cabin,” says Jean Paul Freyssinier, an LRC assistant professor who worked on the project. In a survey conducted inside the original and LED-modified elevators, passengers ranked the low-profile LED installation as consistently better in terms of visibility, comfort, color, and attractiveness of light.

Now the LRC is taking some of the lessons learned from its elevator study and applying them to a more ambitious project: electronic walls and ceilings. Working with the Alliance for Solid-State Illumination Systems and Technologies, an industry group that includes Nichia America, OSRAM Sylvania, and Philips Lighting, they have developed a novel concept for lighting homes and offices that includes interchangeable, modular panels with integrated LED lighting fixtures that “snap” in and out of an electrical grid. Occupants can change the location of light fixtures or introduce new fixtures at will without having to drill holes, patch drywall, call an electrician, or lay out the room according to where the electric sockets are installed. Once in place, the LED panels are controlled by a touch-screen LCD panel mounted on the wall.

Underlying infrastructure

The LRC is not alone in its efforts to demonstrate the current capabilities of white-LED lighting for use in public spaces (see Fig. 3). In fact, one of the earliest adopters of white LEDs for lighting is the architectural design community. Retail giant Wal-Mart is studying the viability of solid-state lighting in the grocery cases at its experimental “green store” in McKinney, TX. Similarly, the oil companies BP and Petro Canada have adopted white-LED lighting systems from TIR Systems (Vancouver, BC, Canada) into their retail gasoline stations in an effort to better position themselves as environmentally friendly energy companies.There are also inroads being made in the use of white-light LEDs for residential buildings. In mid-2005, Permlight (Tustin, CA) introduced the EnbrytenLED line of low-maintenance, low-energy LED lighting products that include step lights, hallway and walkway lighting, cove lighting, pendants, a recessed can light, and a surface-mount ceiling light. In conjunction with Osram Optoelectronics and CREE, Permlight is able to offer standard-efficacy (25-35 lumens/W) or high-efficacy (40-55 lumens/W) luminaires simply by changing the LED module. Permlight is already collaborating with some home builders to provide LED lighting systems for residential communities, including Red Feather Development Group, which is involved in the construction of straw bale homes on several American Indian reservations, and Brookfield Homes, which is constructing a new community in Southern California (Orange County) to house homeless families.

Still, many challenges remain before LED lighting can truly begin to replace conventional light sources for general illumination on a broad scale. In addition to the performance/cost equation and issues such as binning (sorting for brightness), standards still need to be established, potential customers need to be educated as to the value proposition of LED lighting, and an entire infrastructure needs to be created to support the transition to this new technology.

“Like with Edison, the technology would not have succeeded without his working in tandem on building the electrical infrastructure to support it,” Narendran said. “People talk about glowing walls and ceilings with LEDs, but for that to take place, we need to change things like light sockets. Everyone is working to have this technology replace light bulbs, but that is not going to happen. The technologies will coexist, but LEDs and OLEDs will do some things better and will open up whole new applications.”

The right parts

Whether the goal is colored or white light, LEDs are just part of the solid-state lighting puzzle. To maximize their efficacy, LEDs incorporated into a solid-state lighting application must be part of a fully integrated system that features a high-quality optical system. Other key components include:

• Power conversion. Power supplies must convert line voltage to safe, low-voltage DC; too much current will kill the LEDs.

• Digital control/drive. Electronics that tell the LEDs what to do.

• Communications. To control the system from an external source, such as a computer, PDA, or building control.

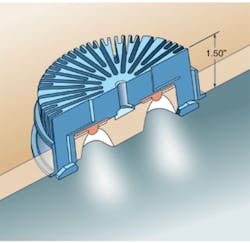

• Distribution/optics. Creates the right lighting effect for the application, eliminates “hot spots” from bright LEDs, and projects illumination exactly where the designer wants.

• Thermal management/luminaire design. Heat must be transferred away from the internal body of the LEDs to maximize performance.

About the Author

Kathy Kincade

Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.