Microchannel cooling ups power capacity for laser-diode bars

ED STEPHENS, RYAN FEELER and JOHN GOINGS

Laser manufacturers have recently made significant improvements to the amount of output power that can be produced by high-efficiency laser-diode bars. Optical output powers greater than 120 W continuous wave (CW) from a single diode bar when packaged on a microchannel cooler have been demonstrated.1 These high powers test the limits of epitaxial structure design, dielectric coating design, and packaging techniques.

While epitaxial and dielectric coating designs have made significant advances recently, many suppliers and consumers of high-power bars have not addressed the packaging developments necessary to take advantage of improved bar performance. Fortunately, new diode package designs are being implemented to provide superior technical solutions while maintaining the size and performance characteristics of traditional diode heat exchangers.

Removing heat

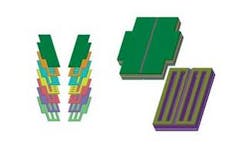

The purpose of packaging a diode bar is to deliver the necessary electrical current and remove the waste heat. Depending on the amount of heat to be removed, a variety of packaging solutions can be implemented, ranging from very small conductively cooled heat exchangers to water-cooled packages and larger microchannel water-cooled arrays (see Fig. 1).

Many of these packages have been in use for years and have a long history of proven reliability. However, these packages cannot provide adequate cooling if a device is operated above its nominal performance limits. As manufacturers develop bars with higher output powers, package improvements must keep pace.

The most efficient method of cooling high-power bars has been to use gold-plated copper heat exchangers with very small (micro) water channels, called microchannel coolers (MCC). This design minimizes the distance between the heat source and the coolant, creating maximum cooling efficiency. Commercial MCC designs allow conventional diode bars to be driven at higher powers because of this improved cooling capacity. However, the use of MCCs demands a more complex cooling system than traditional air- and water-cooled packages. Part of the additional complexity derives from the fact that in commercially available MCCs the electrical current and the cooling fluid must coexist within the cooler. Without proper design of the cooling system, corrosion and erosion will significantly shorten the lifetime of the devices. To minimize this effect, deionized (DI) cooling water must be used, coupled with careful selection of the cooling system components. For many industrial users, requiring DI water has limited the use of MCCs as a practical solution.

By requiring DI water, the water-chiller system not only needs to supply the flow and pressure, but must also actively monitor and control the electrical resistivity and pH of the water. The technical superiority of MCC designs is often complicated by the facility and monitoring system requirements they impose.

The reliability of standard microchannel-cooled stacks has also been questioned. The MCC packaging scheme can be considered less reliable because of the many O-ring seals and weaker electrical contacts involved. Associated packaging failure modes of standard MCC units include water leaks at the O-rings, corrosion due to water exposure, and erosion due to excessive water flow, among others. Because of the complexity of microchannel cooling and the systems and components involved, failures at the packaging level are of increased concern.Next-generation MCC packaging

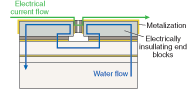

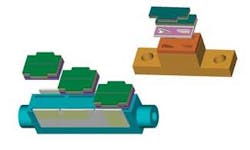

To overcome the disadvantages of legacy MCC packages, we have developed a new microchannel package that places the coolant very close to the diode bar (see Fig. 2). By utilizing the benefits of a conventional MCC, but changing the pattern of water flow, current can be applied to the diode bars without being in electrical contact with the coolant, which eliminates the need for DI water (see Fig. 3).The overall dimensions of new MCC subassemblies and the corresponding bases are form-and-fit identical to other water-cooled pin-finned heat exchangers. Commonly used for radial side pumping of solid-state materials, these types of packages have become prevalent in industry. The new MCC design would allow high-power, high-performance bars on microchannel coolers to be retrofitted and act as a turnkey replacement for the tens of thousands of diode arrays in the field today. This opens the door for bars of more than 100 W CW being developed by many vendors to become a solution for commercial and industrial users. Users would not need to change their mounting scheme, chillers, or fixtures to support bars of the new design.

Pushing performance limits

In the MCC designs used today, the p-side of the diode bar is mounted down to a heat exchanger, but the top portion consists only of the electrical connectors and a mechanical stabilizer. Therefore, heat is removed only through the mounting interface below the bar. Because of its “sandwich” design, the new MCC subassembly can remove heat from both sides of the diode bar because each side is actively cooled. The surfaces used for bonding the cooler to the diode are optimized to achieve improved planarity and thermal transfer. Compared to standard MCCs with a one-sided cooling mechanism, thermal modeling has shown a greater than 30% improvement in cooling efficiency.

Current MCC multibar arrays are assembled by stacking individual coolers on top of one another and frequently bolting them together with thick plates on all sides. Most designs require separations between bars to be 1.6 mm or greater. Double-sided cooling in conjunction with microchannel cooling allows much smaller bar separations to be used, yet still achieves improved performance. Horizontal stacks are created by placing the new subassemblies next to each other. For vertically oriented stacks, a spacer can be used to separate bars. The size of the spacer, which dictates the pitch between the bars in a stack, can be varied based on application needs and desired thermal performance.

Improved reliability

Reliability of MCCs has always been a key concern for potential customers. Failure mechanisms include corrosion due to the aggressive nature of DI water and erosion of interior gold plating due to high water flows.2 The new design involves much more durable interior materials that greatly reduce erosion potential. In addition, O-rings are eliminated because all interfaces are joined with solder, adhesive, or welds. Electrical contacts can be made using braided wires or printed-circuit-board designs, providing a much more reliable connection for high-power bars and the very high drive currents they require.3

The compact nature and improved heat-removal mechanism of this new MCC package will result in reduced output-power degradation rates and minimized packaging-related field failures, facilitating its use as a direct replacement for tens of thousands of traditional water-cooled devices operating in the field.

REFERENCES

1. O. Graydon, Opto & Laser Europe (September 2004).

2. J. Haake and B. Faircloth, “Direct Diode Laser System Requirements for Long Life Micro Channel Coolers,” ICALEO 2004 technical session.

3. E. Stephens, “Multi-Kilowatt CW Laser Diode Arrays,” CLEO/QELS 2005 technical session.

Ed Stephens is director of engineering, Ryan Feeler is diode product specialist, and John Goings is North American sales manager for Northrop Grumman Cutting Edge Optronics, 20 Point West Blvd., St. Charles, MO 63301; e-mail: [email protected].