What happens when you throw a weak laser into a frequency comb?

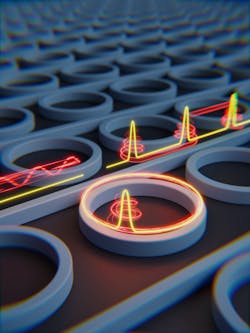

A team from the Joint Quantum Institute, a collaborative group of researchers from the University of Maryland, the National Institute of Standards and Technology (NIST), and the Laboratory for Physical Sciences, has designed and built brighter on-chip optical frequency combs using dissipative Kerr solitons (DKSs; see Fig. 1 and video).

DKSs—self-organized optical waves derived from the interaction between a change in a material’s refractive index upon application of an electric field (the Kerr effect) and dispersion—act as a geometric calculator, explains Grégory Moille, an assistant research scientist at the Joint Quantum Institute and NIST’s Physical Measurement Laboratory.

DKSs also involve the use of micro-ring resonators, typically made from materials such as silicon nitride (see Fig. 2). Essentially, the DKSs rely on the balance of nonlinearity and dispersion, and dissipation and gain.

“If you inject a laser into the micro-ring and design them correctly, the nonlinearity can be compensated by the dispersion,” Moille says. Knowing the nonlinearity allows users to design the dispersion on the micro-ring simply by choosing the right thickness and ring width. “With nanophotonics, you can make any dimensions you want. You can really tailor almost any comb you want,” he says.

And this has been part of the team’s goal: creating DKS-based chip-scale microresonators to develop more efficient, versatile optical frequency combs. Proper thickness and widths for the micro-rings are among its key components. “We want to build a massive comb that spans 1550 nm to 780 nm,” Moille says.

The optical frequency combs Moille’s team created are compact and can be tuned by injecting a weak laser into the frequency comb, optimizing power by more than an order of magnitude in numerous comb teeth.

These optical frequency combs emit a continuous train of short, closely spaced pulses of light, which can be used to measure light waves essentially as if they’re radio waves. Moille says this then enables technologies such as atomic clocks and communications devices to connect to optical waves that fluctuate at significantly higher frequencies—as much as 10,000X higher—than those found in electronics.

The team’s work and recent results were about six years in the making. “Creating this gigantic comb is only one part of it,” Moille says.

Another part is to incorporate the synchronization of an external laser reference point to the DKSs to increase the optical frequency combs’ power levels. Combs based on DKSs typically consume little energy, but their power output is low.

Putting combs into practice

In their work, the team has shown that theoretically, an external reference pump operating at nearly 200 THz allows them to tune the repetition rate of a frequency comb that spans a broader scale. The comb tooth’s phase-matching condition can be tuned to a dispersive wave to boost its output power. Moille’s team demonstrated that, together with the DKSs’ core robustness and its self-balancing, a more than 15-fold power increase is possible for a comb tooth at 388 THz.

The DKS-based frequency combs show a frequency ruler. “All comb teeth are spaced exactly the same, so you can see the distance and you can count and measure,” Moille says.

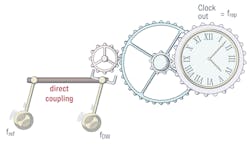

This capability is desirable for atomic clocks, for example, which measure time by monitoring the resonant frequency of atoms with different energy levels (see Fig. 3). The best way to create an atomic clock is by proving the energy transition of an atom—energy known as h-bar omega frequency, which is high.

The Joint Quantum Institute team’s comb uses its frequency as a ruler of value to measure optical frequency with very high precision. This method already uses a laser to produce this frequency with the atom and they have their comb. “We figured why not send this laser into the micro-ring directly to see things happen. When you synchronize, the frequency comb becomes better,” Moille says.

It’s the synchronization that makes the entire process simpler. Ultimately, Moille says the team’s work could lead to the development of high-precision, chip-based devices.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.