Medical applications are a surgical fit for 2 µm lasers

Lasers have become essential for a wide range of industries, including medical applications. For many use cases, laser-based surgery improves accuracy compared to that of a scalpel, reduces the chance of infection, and creates clean cuts from a variety of angles. While laser sources with output wavelengths from 1 to 1.5 µm are widely available and often used, significant advancements in 2 µm lasers have led to their rapidly increasing popularity.

Evolution of 2 µm lasers

The first 2 µm laser sources were large and expensive liquid-nitrogen-cooled devices. Today, 2 µm diode lasers can be as small as 30 mm long, with even smaller 2 µm fiber lasers available. Both pulsed and continuous-wave (CW) emission are achievable.

The two rare-earth elements most used as laser gain dopants for both CW and pulsed laser operation are thulium (Tm3+) and holmium (Ho3+). Ions from these elements are used to achieve laser emission in many different host crystals and glass fiber types. Thulium lasers prove to be a better option for CW operation, while holmium better aligns with pulsed and Q-switched lasers because of the higher gain of holmium-doped crystals. Another advantage of thulium lasers is that their ions can be excited using commercially available laser diodes with wavelengths of 800 nm. Holmium requires a 1.9 µm pump source to excite the ions.

2 µm absorption in water

2 µm laser sources are well-suited for precise surgical applications because of the high absorption of 2 µm wavelengths by water molecules, which comprise most biological tissue. The stretching and bending vibrations of water’s O-H bonds match the vibrational frequency of 2 µm laser pulses.

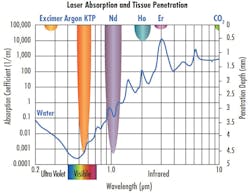

Determining the exact amount of absorption attributed to a specific vibrational mode is difficult because all these effects are coupled—the spike in absorption is easily observable. Water’s absorption spectrum and the depth of tissue penetration for different laser types is shown in Figure 1. At 2 µm, the combination of the absorption peak and penetration depth around 0.6 mm at 2 µm make this wavelength region optimal for laser surgery. There is another absorption peak at 3 µm, but the penetration depth at that wavelength is not high enough for surgical applications.

Coagulation under 2 µm radiation

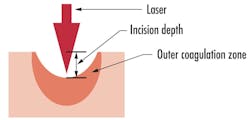

2 µm lasers cause a small injury zone around 0.5 mm in size because of the high level of absorption. This improves the accuracy of cuts made during surgery with minimal damage to surrounding areas. Also, coagulation—when blood modifications form a clot by changing from a liquid to semi-solid state—happens during 2 µm radiation exposure (see Fig. 2). This clotting decreases the amount of bleeding, allowing surgery to be cleaner and more efficient.Other laser types lead to even more coagulation. However, too much clotting can cause complications after the surgical procedure. The coagulation level of 2 µm lasers is a beneficial middle-ground with a coagulation depth around 0.1 to 0.2 mm. This balances bleeding mitigation with thermal injury and the prevention of post-procedure complications. Because surgery is a very precise process, the depth of cuts needs to be finely controlled to reduce damage to the underlying tissue. The speed of cutting and vaporization of 2 µm also remain relatively constant no matter how vascular the biological tissue is, making 2 µm laser systems flexible for working with different types of tissues.

Eye safety, surgical applications

2 µm wavelengths are deemed safe for eye exposure—the typical range is around 1.4 to 2.4 µm, as these wavelengths are strongly absorbed in the vitreous body of the eye and do not reach the retina. The intensity threshold for irreversible eye damage of a 2 µm laser is also much higher than the threshold for shorter wavelengths such as 1 µm. But even with these safety benefits, 2 µm beams can still potentially damage other parts of the eye besides the retina, so all laser safety precautions should still be taken.

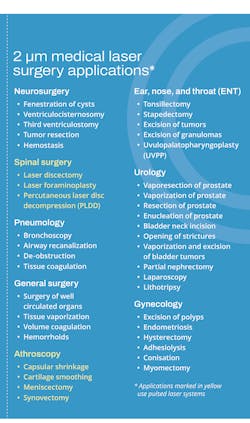

The properties of 2 µm lasers discussed above, including their relatively constant cutting and vaporization speed across many different tissue types, makes them ideal options for many different surgical applications. The table shows a wide variety of different use cases for these lasers spanning areas such as neurosurgery, ear/nose/throat, pneumology, spinal surgery, gynecology, urology, and arthroscopy. Erbium lasers with longer wavelengths including 2940 nm and 2790 nm are also used for acne removal and skin rejuvenation.Laser sources in the 2 µm spectral region have proven very useful in medicine applications. Their high absorption in biological tissue, small thermal injury zone, and eye-safe wavelengths will likely continue boosting their popularity and become more widely used for laser surgery.

About the Author

Cory Boone

Cory Boone is technical marketing manager at Edmund Optics. He is responsible for managing the creation of technical marketing content, including application notes, published articles, web copy, email campaigns, video scripts, trade show materials, case studies, and other marketing literature. He plans the company’s technical content strategy and acts as the technical voice of the marketing department. Cory is also active in educational outreach and spreading general awareness of the optics industry. He received a B.S. in Optical Sciences and Engineering along with minors in Math and Material Science Engineering from the University of Arizona.