On-chip electro-optic frequency comb overcomes efficiency-bandwidth tradeoff

On-chip frequency comb sources haven’t been widely embraced for commercial adoption yet because their performance tends to be limited by either low conversion efficiency, too high repetition rate, or narrow bandwidth.

“One of the biggest applications for combs is metrology, a.k.a. precision measurement, so they can be used in LiDAR for spectroscopy applications and environmental monitoring,” says Lončar, who is a professor of electrical engineering. “This is what we originally had in mind.”

But the team’s latest device now opens the door to applications in astronomy, communications, frequency metrology, optical atomic clocks, optical computing, ranging, spectroscopy, and quantum information—to name a few. And it’s also a platform to explore new areas of the optical physics realm that involve multiple nonlinearities.

Building on past advances

About 10 years ago, Lončar started working on microresonator-based Kerr frequency combs in diamond, taking advantage of large third-order nonlinearity and the wide transparency window of this material platform.

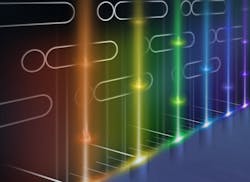

At about the same time, he and colleagues began exploring the opportunities offered by a thin-film lithium niobate (LiNbO3) photonics platform (see Fig. 2). Lithium niobate is a well-known material in integrated optics and optoelectronics: it’s used for electro-optic modulators, devices that translate information from an electrical domain to an optical domain, which are essential components of fiber-optic networks that form the backbone of the internet.Working with LiNbO3 can be difficult, and “people thought for many years it’d be impossible to nanostructure it,” says Lončar. “We showed this wasn’t the case almost five years ago and were able to demonstrate ultralow-loss devices on this material platform.” Next, the team used the platform to realize efficient electro-optic modulators that featured low on-chip energy consumption and a very high bandwidth.

By 2019, Lončar and his team demonstrated the first stable on-chip frequency comb that could be controlled via microwaves. It was an electro-optical frequency comb built on the thin-film lithium niobate photonic platform pioneered by his lab.

“Through discussions with my colleague Joseph Kahn, a professor of electrical engineering at Stanford, we were inspired to consider using our electro-optic modulators to realize resonator-based electro-optic frequency combs that rely on a second-order nonlinear process,” he says.

When his team input one color of light at a 1550 nm wavelength and applied a 30 GHz microwave signal, the device generated a frequency comb consisting of many lines/colors of light separated by 30 GHz. “In a way, we brought back an old approach to making frequency comb sources,” says Lončar. Although this device spanned the entire telecommunications bandwidth and was tunable, it had limited efficiency.

In 2021, his lab developed a coupled-resonators electro-optic device and used it to demonstrate an on-chip frequency shifter and beam splitter. By taking advantage of this platform, they demonstrated the ability to change the frequency of light across the 100 GHz range with nearly 100% efficiency.

Efficient electro-optic modulation

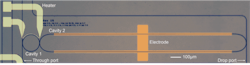

The team’s latest advance builds upon their earlier work to address the challenge in resonator-based electro-optic frequency combs: the efficiency-bandwidth tradeoff. By combining a coupled resonator with an electro-optical frequency comb, they discovered they could simultaneously improve efficiency and bandwidth.

In Lončar’s first frequency comb work reported in Nature in 2019, the efficiency of the process was below 3% and limited by the intrinsic property of the resonator comb source—the more microwave power is applied in hopes of generating a broader spectrum, the more difficult it is to inject laser light into the resonator, which limits the conversion efficiency and bandwidth.

By comparison, the team’s most recent work overcame this limitation by coupling two resonators together (see Fig. 3). “We demonstrated 30% efficiency and an optical span of 132 nanometers—two orders of magnitude improvement in the power we can generate, and it can be further improved,” he says.One resonator plays a role bringing light efficiently inside the second resonator, and the second resonator is where the comb is generated. “Coupling resonators allows us to decouple this tradeoff of efficient injection of light and efficient comb generation,” Lončar says.

Already having developed the fastest and most efficient electro-optic modulators, which are crucial components of electro-optic frequency comb generators, helped inspire their latest work. “It was a bit opportunistic,” Lončar explains. “We had lemons, so we decided to make lemonade. But now we’re realizing these combs have even nicer properties than our original ones—and this is a very active area of research.”

Femtosecond pulses

To get very short pulses, Lončar’s team takes light from a continuous-wave laser and passes it through coupled resonators while applying a microwave signal.

“So now we have a very efficient on-chip femtosecond pulse source (336 fs) we think will be useful for other applications in nonlinear optics, sensing, and computing,” he says. For example, it allowed them to explore an entirely new regime of nonlinear optics that combines the process of electro-optic frequency comb generation with the more traditional approach of a Kerr frequency comb.

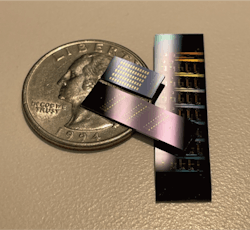

Frequency combs are currently broadly used for astrophysics to analyze the spectra of light coming from a distant object in the universe. But the ones in use today tend to be bulky and are primarily used for ground-based measurements. “Chip-scale combs like the one we’ve developed could be used on satellites, for example,” says Lončar. “To me, enabling new discoveries in astrophysics would be a really cool application.”

The team’s work should help pave the way to practical optical frequency comb generators. “Long story short: electro-optical combs are making a comeback because they’re more efficient than other combs and can generate an appreciable amount of power,” says Lončar. “And they’re very easy to operate.”

FURTHER READING

M. Zhang, C. Wang, R. Cheng, A. Shams-Ansari, and M. Lončar, Optica, 4, 12, 1536–1537 (2017); https://doi.org/10.1364/optica.4.001536.

C. Wang et al., Nature, 562, 101–104 (2018); https://doi.org/10.1038/s41586-018-0551-y.

M. Zhang et al., Nature, 568, 373–377 (2019); https://doi.org/10.1038/s41586-019-1008-7.

Y. Hu et al., Nature, 599, 587–593 (2021); https://doi.org/10.1038/s41586-021-03999-x.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.