Special resin, crossed laser beams enable fast 3D microprinting

A team of Karlsruhe Institute of Technology (KIT), Heidelberg University (both in Germany), and Queensland University of Technology (Australia) researchers recently developed a special resin and a dedicated 3D printer to complete a microstructure—within the blink of an eye. In contrast, commercial 3D printers typically require a few seconds to print merely a single layer.

Sluggish print speeds inspired the team to attempt to speed up 3D printing of microscale objects.

“Established 3D microprinters rely on two-photon absorption, a technique pioneered by Shoji Maruo,” says Vincent Hahn of KIT’s Institute of Applied Physics. “Most two-photon 3D printers print voxels serially, one voxel at a time. To parallelize 3D microprinting, we borrow a concept commonly used in the microscopy community: a light sheet, which is a flat laser beam, similar to a sheet of light.”

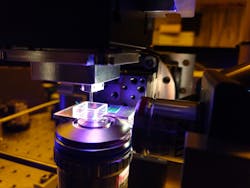

Polymerization is method commonly used for plastic 3D printing, in which a liquid resin is solidified by light. In most 3D printing methods, only one color of light is required to solidify the resin. But in this case, the team’s resin only solidifies when irradiated by light of two different colors simultaneously—red and blue laser beams (see figure and video).

“The blue laser projects layers of the 3D object and switches the resin from its pristine state to an inert intermediate state,” says Vincent Hahn of KIT’s Institute of Applied Physics. “The red light sheet-shaped laser beam then kicks off the solidification process. But in all locations not exposed by the red laser, the resin eventually relaxes and returns from the intermediate state back to its pristine state.”

This relaxation process takes time and can limit the overall printing speed. “The resin we present relaxes within less than a millisecond, which is more than three orders of magnitude faster than previous resins,” Hahn says.

Crossed beams

Along with the resin, the team also developed a dedicated 3D printer capable of exploiting the resin’s fast relaxation time. This printer uses blue laser diodes to project images into the liquid resin via a high-resolution display with a high frame rate, and the red laser is formed into a thin light sheet beam that crosses the blue beam vertically within the resin.

Coolest aspect of this work? “The speed at which individual 3D objects can be printed,” says Hahn. “We were overwhelmed when we observed the first 3D-printing process—in fact, it’s almost too fast to observe.”

Biggest challenge? “Designing a suitable resin—it involves literature research, chemical synthesis, and screening experiments under various exposure conditions,” he says.

The group’s target application is to print microstructured 3D metamaterials with feature dimensions on the centimeter scale, but they also envision its use for biological applications such as 3D-printing custom tissue scaffolds.

“One hurdle we’re facing now is a loss in 3D printing resolution when printing for an extended period,” says Hahn. “We’re currently improving the resin and the 3D printer to clear that hurdle.”

FURTHER READING

V. Hahn et al., Nat. Photonics (2022); https://doi.org/10.1038/s41566-022-01081-0.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.