Shaping the light: The advent of digital lasers

Tailoring light distribution to match specific experimental or industrial needs is a quest as ancient as optical engineering. However, it is not until the invention of the laser in 19601 that humankind could start taking advantage of coherent light toward this end.

While the first fiber laser was introduced soon after,2 it did not appear on the market until the late 1980s. This was simultaneous with the introduction of the chirped-pulse amplification (CPA) technique,3 which allows the amplification of ultrashort pulses by stretching the power distribution over time. To further scale up both peak and average powers, the concept of coherent beam combining (CBC) was recently demonstrated.4-6 It relies on the distribution of power to several beams throughout the amplification process before a final coherent addition.

XCAN, a CBC femtosecond fiber laser, has been developed by École Polytechnique and Thales (France). It is based on 61 tiled channels operating in both high peak and average power (100 GW/1 kW) regimes.7 Each channel is seen as a near-field individual pixel where amplitude and phase can be addressed independently. With its highly scalable, tiled-aperture architecture, this prototype could lead to a new era of full digital lasers with potential for light shaping in various power regimes.

Dedicated light distribution control to optimize material processes is an important industrial request with very different and peculiar shaping requirements.8 Although the XCAN architectural approach can generate arbitrary shaped-light distribution, the experimental focus is on orbital angular momentum (OAM) laser beam generation. Such beams carry helical phase fronts9 and, therefore, the hexagonal tiling distribution of the XCAN appears perfectly suited for such phase-symmetry generation. Moreover, OAM beams have a wide range of applications — from optical manipulation,10 quantum optics,11 and imaging12 (such as in astronomy13 or fluid-flow characterization14) to optical communications and cryptography.15, 16 It is also important to consider applications requiring much higher power, including microbunching instability reduction in free-electron laser setups17 or propagation of ultra-intense laser beams18 (for channeling lightning strikes or detecting atmospheric pollutants19,20).

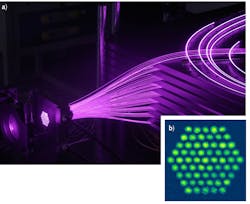

Traditional methods for generating OAM beams generally rely on laser cavity tuning,21 phase plates,22 axicons,23 and spatial light modulators (SLMs).24,25 Laser cavity tuning and phase plates allow high output power operation but lack tunability, as a different cavity design or optical element must be engineered for each specific transverse beam distribution. SLMs offer high tunability,26 but are limited in output power (peak and average) by optical damage thresholds. The XCAN digital laser provides an alternative, more versatile approach with high throughput power, tunability, and real-time generation of OAM beams. In XCAN’s tiled-aperture configuration, 61 fiber-amplified laser beams are distributed in the near-field side-by-side as close as possible to each other in a planar hexagonal array arrangement (see Fig. 1). Figure 1a also shows a hexagonal lenslet for simultaneously collimating the beams.

The CBC is achieved simply when focusing this composite large pupil with a single lens. The electric field transverse distribution observed in this lens focal plane is the result of the coherent addition of all 61 tiled beams accurately phased together. When compared to filled aperture,27 tiled-aperture CBC is inherently limited in efficiency to the power concentrated into the main lobe in the far field (theoretically 67%). However, it offers an unrivaled agility in terms of far-field beam shaping. This key property is an unachievable perspective for filled-aperture CBC laser systems where all near field sub-pupils are superimposed onto each other.

The technological choices made while integrating the laser were driven while making sure to keep its high scalability potential. This is especially true at the final power fiber-amplifier level, where flexible fiber solutions engineered by Optical Engines Inc. (based on NKT Photonics fibers) have been favored because they provide compactness, low cost, and scalability. Pre-amplifying stages rely on Keopsys fiber amplifiers. The phase of each individual beam is real-time (kilohertz) controlled through the combined use of variable optical delay lines and piezomechanical fiber stretchers packaged together by Idil Fibres Optiques. The phase stabilization is performed using a collective interferometric measurement method through active phase control and a stochastic parallel gradient descent algorithm. This setup generates a custom set of phases. Each beam amplitude (i.e., power) can be adjusted through amplifier gain control. Figure 1b illustrates the near-field interference patterns of 61 fibers, demonstrating the digital laser concept.28

By generating OAM helical beam phases digitalized over XCAN 61 pixels, a characteristic “donut-shaped” far-field transverse distribution can be obtained (see Fig. 2a). The laser setup has been operated in subpicosecond as well as kilowatt average power regimes while generating OAM beams.XCAN’s highly scalable architecture could soon be considered the advent of a new laser architecture paradigm: the digital laser. Such an approach carries a high potential for greatly broadening the field of applications of structured light beyond OAM centrosymmetric beams.14,17 It indeed associates high peak (femtosecond regime operation) and average (kilowatt regime) powers, thanks to its diode-pumped, ytterbium (Yb)-doped fiber amplifying chain architecture. Compact and scalable by nature, it has been conceived and implemented to be compatible with up to 10,000 channels, paving the way to high-resolution transverse amplitude and phase laser beam control.

The real-time adjustability of these beam properties (currently up to the kilohertz regime) offers an extra degree of freedom for applications—drilling, cutting, or soldering of material, for instance—requesting dynamic energy or power distribution control.

REFERENCES

For the full list of references, please see http://bit.ly/PolytechniqueReferences.

About the Author

Arnaud Brignon

Team Leader, Thales Research & Technology

Arnaud Brignon is a team leader at Thales Research & Technology (Palaiseau, France). The main research areas of his team include coherent laser beam combining, photonic integrated circuits, and quantum sensing. A Fellow of the Optical Society of America, he received the Fabry-de Gramont Prize from the Société Française d’Optique, the Fresnel Prize from the European Physical Society, and the MIT Technology Review’s Young Innovators Award from the Massachusetts Institute of Technology (MIT).

Eric Lallier

Optical Scientist, Thales Research & Technology

Eric Lallier is an Optical Scientist at Thales Research & Technology (Palaiseau, France).

Christian Larat

Optical Scientist, Thales Research & Technology

Christian Larat is an Optical Scientist at Thales Research & Technology (Palaiseau, France).

Jérôme Bourderionnet

Optical Scientist, Thales Research & Technology

Jérôme Bourderionnet is an Optical Scientist at Thales Research & Technology (Palaiseau, France).

Matthieu Veinhard

Laser Systems Engineer, XCAN Project

Matthieu Veinhard is a Laser Systems Engineer for XCAN Project at École Polytechnique (Palaiseau, France).

Ihsan Fsaifes

Ihsan Fsaifes received his M.S. and PhD degrees in electronic and communication from the Ecole Nationale Supérieure des Télécommunications (Télécom ParisTech; Paris, France) in 2003 and 2007, respectively. He joined Ecole Polytechnique in 2015. His research interests include fiber lasers, coherent beam combining, and phase-sensitive optical amplifiers and their applications.

Louis Daniault

Dr. Louis Daniault has a permanent position at the laboratories of École Polytechnique (Palaiseau, France). His research activities focus on ultrafast high-power lasers and their applications.

Séverine Bellanger

Laser Systems Engineer, XCAN Project

Séverine Bellanger is a Laser Systems Engineer for the XCAN Project at École Polytechnique (Palaiseau, France).

Jean-Christophe Chanteloup

Head, XCAN Project

Dr. Jean-Christophe Chanteloup graduated from École Supérieure d'Optique in 1994 and received his PhD from Ecole Polytechnique in 1998. He joined the Centre National de la Recherche Scientifique in 2000. His fields of interest are adaptive optics on laser systems, wavefront sensing, and diode-pumped solid-state lasers (DPSSLs). Since 2015, he has been in charge of the École Polytechnique XCAN research program dedicated to coherent beam combination of dozens of fiber-amplifying channels. He is the author or co-author of 150+ communications in international conferences or papers in scientific reviews.