SRS remains a major development challenge for multikilowatt fiber lasers used in industrial applications

Stimulated Raman scattering (SRS), a well-known nonlinear phenomenon, results when optical intensity increases beyond a threshold value within an optical material—for example, in the core of the optical fiber serving as the gain medium of a fiber laser. Once reached, SRS limits the achievable output power at the desired wavelength because most of the added energy provided to the laser is wasted as it’s transferred to the Raman (Stokes) wavelengths.

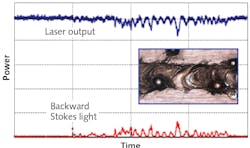

Worse yet, SRS optical feedback reflected from the workpiece can cause severe issues, including laser instabilities and damage to a fiber laser’s pump diodes. Instabilities in the laser output power and/or beam quality can impact cutting and welding quality if the laser output starts to jiggle.1 Reliability is key in end-user industrial applications, especially when considering increasing throughput with more powerful lasers.

Transverse mode instability

Despite tremendous progress in SRS management over the past decades, the output power of standalone, near-single-mode ytterbium (Yb)-doped continuous-wave (CW) fiber lasers barely exceeds a few kilowatts. One of the reasons is transverse mode instability (TMI), another critical technical challenge that emerged around 2009 and seriously hindered multikilowatt system development. The problem is that thermally induced TMI, another nonlinear effect that occurs in optical fibers, suddenly sets in upon reaching the system-specific average power limit.

The symptoms include step-like beam profile instabilities in the kilohertz regime, a showstopper for a vast majority of applications. TMI has been the object of considerable attention in the scientific and industrial communities since its discovery. The good news is that its physical origin is now better understood, allowing the development of effective suppression schemes.2

The tricky part is that TMI suppression options often penalize SRS suppression. The right balance between TMI and SRS management must be found, while also addressing other usual constraints like thermal management, technological limitations, reliability considerations, cost imperatives, and so on. This is quite a puzzle.

SRS vs. TMI management

It is well known that the SRS power threshold is proportional to the effective mode-field area and inversely proportional to the effective length of the fibers. Therefore, many SRS mitigation strategies have been designed around the principles of increasing the size of the fundamental mode and keeping the fibers as short as possible.

For instance, reducing the length of the delivery cable from 15 m to 10 m is quite simple to implement. The downside is that the result is a product that is less convenient for the end user. Opting for larger core diameters (for example, 100 µm or more instead of 50 or 25 µm) can also help reduce the SRS generated in the delivery cable, at the expense of the laser brightness. This might be suitable for some applications.

Trying to minimize the length of the passive fiber as much as possible sounds like a no-brainer, and there isn’t much improvement to be expected here. Besides, several approaches exist to reduce the gain fiber length. First, one can design the laser to be shorter in length and accept wasting pump photons. This is a simple approach, but not very efficient. In addition, the wasted pump must be managed to avoid reliability issues, which can add complexity to the system. A more-elegant way to minimize gain fiber length is by increasing the absorption of the pump. This can be achieved in different ways: choosing fibers with higher core/cladding area ratios, and/or fibers with higher Yb concentrations, and/or pumping at 976 nm instead of 915 nm.

Increasing core/cladding area ratio

This enhances the probability that a pump photon will be absorbed for a given fiber length and Yb concentration. For instance, commercially available 25/250 (core/cladding diameter in microns) and 30/250 fibers are specified with typical absorption in the range of 1.6 to 2.0 dB/m at 915 nm, compared to 0.4 dB/m for the ubiquitous 20/400 fiber. However, reducing the cladding dimensions means more watts per unit area at the pump guiding interface (glass/low index polymer interface), which also means a reduced pump-power handling for a given polymer. The workaround is to go for a triple-clad fiber (TCF), which includes two embedded pump waveguides to reduce the intensity seen by the polymer, but TCFs are generally more expensive than double-clad fibers (DCF). Increasing the Yb-doped core diameter for a given pump waveguide diameter also increases the core/clad area ratio and further helps reduce the intensity in the core, which promotes higher SRS thresholds. However, fibers with larger cores tend to support more higher-order modes (HOMs), which in turn favors the onset of TMI.

Increasing Yb concentration

Minimization of the gain-fiber length can also be achieved by increasing the concentration of Yb in the fiber core. Still, this approach involves a higher thermal load on the fiber, which tends to lower the TMI threshold. Furthermore, the photodarkening (PD) losses grow quadratically with Yb concentration, which also strongly contributes to generate heat within the fiber core and lower the TMI threshold.2

Pumping at 976 nm instead of 915 nm

Since powerful (>300 W) and affordable (~ $2/W) high-brightness pump diodes became available, pumping at 976 nm has increased in popularity. When compared to pumping at 915 nm, the strong Yb absorption peak at 976 nm minimizes fiber length. For 20/400 fibers having absorptions of ~0.4 dB/m at 915 nm, typical pump absorptions reach ~1.2 dB/m.

The reduced quantum defect allows improved optical-optical efficiencies (up to 90%) with shorter fibers. When pumping at 976 nm, TMI trends in the opposite direction, due to the increased heat load and lower gain saturation.2

SRS mitigation strategies relying on the use of shorter fibers therefore generally run counter to pushing the limits of TMI. However, several other design strategies can help manage SRS and TMI at the same time.

Bi-pumping or side-pumping

If willing to invest in a more complex design with higher associated costs, pumping schemes that allow for operating at the optimum gain distribution, balance the reduction of the peak nonlinear phase, also known as the B integral (for SRS mitigation), and thermal gradients and PD-induced heat losses (for TMI mitigation).

Fiber with high losses at SRS wavelength

Another approach uses a tailored, photonic-bandgap delivery fiber that achieves high losses at the Stokes wavelengths to suppress SRS.1

Optimized fiber Bragg grating reflector design

Widening the bandwidth (~1 nm and upwards) of the fiber Bragg grating (FBG) reflectors increases the SRS threshold. The dynamics of lasers with narrower bandwidths exhibit more-frequent high peak power spikes, resulting in greater SRS conversion.3 So far, this fairly simple solution hasn’t shown any detrimental TMI management tradeoffs.

Lower PD

Because PD increases the thermal load on the fiber, it strongly influences the TMI threshold. Fibers exhibiting low PD help mitigate TMI, and higher TMI thresholds enable working with shorter fibers and/or larger mode area fibers to mitigate SRS. Therefore, PD losses become critical for increasing TMI and SRS thresholds, and should be given extra attention when selecting a gain fiber.

Raman FBG filter

This approach has gained a lot of attention recently. It is based on the suppression of Stokes photons with FBG filters—for instance, Chirped Tilted FBGs (CTFBGs). CTFBGs block the Stokes photons and redirect them into the cladding of the fiber, where they can be absorbed using a cladding light stripper.

The attenuation bandwidth of these filters can be large (>15 nm) and deep (>20 dB) at the Stokes wavelength.4 The minimization of the insertion loss (IL) is very important when adding components in the optical chain. IL in the range of 0.1 to 0.15 dB can readily be achieved for CTFBGs and is constantly improving.

CTFBGs can be designed to be bidirectional to help manage Stokes light reflected from the workpiece. They may also be beneficial in limiting SRS in master-oscillator power amplifiers (MOPAs), which tend to have higher TMI thresholds than oscillators.2 In general, filtering SRS at its source allows for the use of longer fibers, which goes hand in hand with TMI mitigation and is welcomed in some laser architectures such as those relying on tandem pumping.

CTFBGs for multikilowatt fiber lasers are now commercially available5 and are being adopted by a growing number of laser manufacturers. Figure 2 shows an example of SRS mitigation with a commercial CTFBG from TeraXion in an industrial fiber laser. The SRS peak can be maintained -40 dB below the laser peak at an output power of 3 kW. Without a filter, this same ratio is reached below 1 kW.In a nutshell

This article shows how scaling the power of fiber lasers goes beyond increasing the SRS threshold by building on improved versions of traditional approaches used so far, and includes making compromises when balancing the common tradeoffs of dealing with other equally serious limitations such as TMI, whose management tends to oppose that of SRS.

There is no one-size-fits-all solution and sustained worldwide development efforts continue to help refine understanding of the phenomena that prevail in fiber lasers at multikilowatt regimes. Still, SRS remains a major challenge that must be controlled to ensure reliable, high-throughput industrial laser processes.

To that effect, this article discusses design options given current knowledge about SRS and TMI, as well as innovative solutions relying on new optical components such as specialty fibers and CTFBG-based Raman filters.

REFERENCES

1. Y. Wang et al., Proc. SPIE, 11260, 1126022 (Feb. 21, 2020); https://doi.org/10.1117/12.2545832.

2. C. Jauregui, C. Stihler, and J. Limpert, Adv. Opt. Photon., 12, 429–484 (2020).

3. G. Brochu et al., Proc. SPIE, 10085, 100850N (Feb. 22, 2017); https://doi.org/10.1117/12.2248336.

4. G. Brochu et al., Proc. SPIE, 11261, 112610P (Feb. 21, 2020); https://doi.org/10.1117/12.2548351.

5. See http://bit.ly/TeraXionRef5.

About the Author

Pascal Deladurantaye

Product Line Manager of High-Power Laser Components, TeraXion

Pascal Deladurantaye is Product Line Manager of High-Power Laser Components at TeraXion (Québec City, QC, Canada).

![FIGURE 2. SRS mitigation with a commercially available CTFBG [5] in a 3 kW industrial fiber laser; output spectrum without filter (a) and spectrum with filter (b) are shown. FIGURE 2. SRS mitigation with a commercially available CTFBG [5] in a 3 kW industrial fiber laser; output spectrum without filter (a) and spectrum with filter (b) are shown.](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2021/05/2105LFW_del_2.609408ee34cbe.png?auto=format,compress&fit=max&q=45&w=250&width=250)