On-chip OPO has tunable range extending from IR to green

Researchers at the National Institute of Standards and Technology (NIST; Gaithersburg, MD) and the University of Maryland (College Park, MD) have developed a silicon nitride (Si3N4) microchip-based optical parametric oscillator (OPO) that can produce light at wavelengths across much of the visible spectrum (red, orange, yellow, or green), in contrast to previous on-chip OPOs that could only reach the far-red end of the visible spectrum. The technique has applications in precision timekeeping and quantum information science, which often rely on atomic or solid-state systems that must be driven with visible laser light at precisely specified wavelengths. The approach suggests that a wide range of such wavelengths can be accessed using a single small-scale platform instead of requiring tabletop lasers or a series of different semiconductor materials. Constructing OPOs on microchips also provides a low-cost way to integrate lasers with the photonic integrated circuits (PICs) needed for optical clocks and quantum communication systems, as the microchip OPO is suitable for mass production.

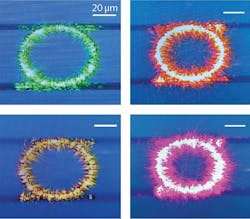

Although researchers have made great progress in creating compact, high-performance lasers at the near-infrared (near-IR) wavelengths used in telecommunications, it has been challenging to achieve equivalent performance at visible wavelengths. Some scientists have made strides by using semiconductor materials to form compact visible-light lasers. In contrast, the NIST and University of Maryland researchers focused on using on Si3N4, which has a pronounced nonlinear response to light and thus the ability to frequency-convert light. The on-chip OPO is based on third-order optical parametric oscillation (OPO), in which the nonlinear material converts incident light in the near-IR into two different frequencies. One of the frequencies is higher than that of the incident light, placing it in the visible range, and the other is lower in frequency, extending deeper into the infrared (IR). The OPO's microring resonator has a radius on the order of 25 μm and a thickness of 500 nm and sits on a silicon dioxide (SiO2) substrate. To achieve an output wavelength tunable from 759 to 567 nm, the OPO's input pump laser is tuned from 776 to 766 nm with the output idler tuned from 793 to 1180 nm.

To create many visible and IR colors, the team fabricated dozens of microresonators, each with slightly different dimensions, on each microchip. The team showed that this strategy enabled a single near-IR laser that varied in wavelength by a relatively small amount to generate a wide range of specific visible-light and IR colors, with the input frequency tuning span magnified by a factor of approximately 25 in the output. Reference: X. Lu et al., Optica (2020); https://doi.org/10.1364/optica.393810.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.