Bioimaging/Light Sources: Flexible LED light sources for scientific applications

PAUL FOURNIER and RAFAL PAWLUCZYK

Low cost, long lifetime, high efficiency, compactness, and robustness make LEDs superior to traditional incandescent and fluorescent light sources for a wide range of applications. These qualities account for the rapid adoption of LEDs, and their ubiquity in daily life—through phones, TVs, cars, and homes.

For life sciences and other applications in science, imaging, and engineering, LEDs offer a level of flexibility unsurpassed by other light sources, along with an ability to quickly switch on and off, and the availability of narrow spectral emission bands. Using low-voltage and direct-current power supplies, LEDs are easily controllable via digital and computer systems. In addition, they can be easily controlled for temperature to improve spectral stability. Finally, their small emitter size enables relatively straightforward and efficient coupling to optical systems.

Achieving broadband spectra

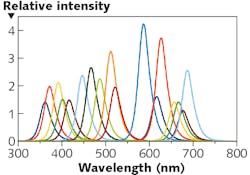

One of the most attractive aspects of LEDs for scientific applications is their coverage of a broad range of fairly narrow wavelengths (see Fig. 1). High-power versions (>100 mW total output from approximately 1 mm2 emitter) are available from 365 to 940 nm, with many options in the near-infrared (near-IR) and up to 1600 nm at slightly lower powers. This facilitates combining of multiple emitters to generate a broadband spectral distribution that can be tailored to specific needs, and precision control, allowing for the full and continuous spectral profile generation required for broadband spectroscopy. While sources of comparable functionality were possible previously, LED illumination systems enable this at a better cost-to-performance ratio.The challenge has been how to combine multiple emitters without the effort and cost associated with applying dichroic filters. The core feature for some LED light sources is the ability to generate a broadband spectral output profile: the outputs of individual LEDs are coupled into optical fibers, which can then be bundled together and arranged to obtain a uniform, high brightness combined output. Combining the light engine with an optical fiber also improves the flexibility and performance of the optical system for beam delivery.

Individual LEDs have a fairly narrow-band spectral output, with Gaussian-like distribution roughly centered at a specified wavelength. Combining multiple narrow-band profiles results in a continuous emission spectrum. By varying the number of emitters, their output intensity, and out-coupling, it is possible to produce very complex spectral profiles.

Generating a specific spectral profile begins with segmenting the range into spectral bands corresponding to available LED emitters. The fidelity of the fit is compared with the requirements, with additional emitters added as necessary. This spectral fit results in a theoretical light engine spectral profile closely matching the desired output.

Coupling and mixing

The coupling of an LED to an optical system or fiber is best understood by considering the concept of étendue. This is the light-gathering capacity of an optical element, expressed as the product of its spatial size and the angular acceptance. It is considered invariant for a given optical system, meaning that any magnification of the spatial size will result in inverse magnification of the angular spread—and vice-versa.

This has practical implications for illumination systems, as light from a source with large étendue (filament bulb, LED) cannot be coupled into a system with a smaller one (optical fiber) without losses. Thus, the most efficient coupling from the LED emitter to a fiber can be achieved by placing the fiber directly at the emitter. Adding any optics between the two will only lower the coupling efficiency.

To put this in perspective, a typical high-power LED has an emitter roughly 1 mm2 and a useful emission cone of 120 degrees. Coupling its output into a 600 μm core fiber with an NA of 0.22, the collection efficiency is about 3–4%. While this is low, for an LED with output in the hundreds of milliwatts, this translates into significant light output when combining many LED emitter/fiber pairs to produce a broadband spectral profile. Due to its small size, an LED directly coupled to a 600 μm fiber will achieve power densities of a few watts per square centimeter.

Traditionally, a few sources are staggered in a series using dichroic filters for a common output. In this type of setup, the number of individual channels is limited due to the complexity of aligning and superimposing multiple dichroic filters.

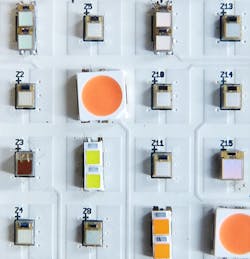

One solution is having discrete LEDs coupled to individual fibers and then bundling these fibers together to create a multicolor output that can be spatially homogenized with very low loss using an integrating rod (see image at top of page). This approach offers an additional degree of control over the resulting spectral profile as both the fiber size and count can be used for spectral weighing. It's possible to construct light engines with up to 18 separate emitters in this way. In principle, the number of emitters could be higher, but is determined primarily by the complexity of the desired spectral profile (see Fig. 2).Enabling applications

Emerging multimodal imaging and stimulation techniques require advanced illumination systems that offer broad spectral coverage, individual narrow bandwidth, excellent stability, and fast response.

Most replacement microscope illumination systems based on LEDs generate essentially white light to attain high color-rendering index (CRI) by using either blue pumped phosphor LEDs or a combination of red-green-blue discrete emitters. In fluorescence imaging, however, narrow spectral bands are used to excite particular fluorophores. Having a single source that can excite multiple dyes or proteins quickly is an advantage. A fiber-coupled LED light engine can be configured for a particular sequence of tests required.

Accurate and reliable reproduction of a solar emission spectral profile is of great importance for life sciences and various other applications. The Sun has a broad spectral profile that matches a high-temperature black body around 5900 K. At 10% intensity, it spans from about 300 nm to over 2000 nm, with large band of atmospheric absorption above 750 nm. Most applications, though, require only a section of the entire solar spectrum to be approximated. An 18-emitter LED light source matches the reference solar spectrum to within 10% of irradiance in any region between 380 and 800 nm. The output of the light source can be modified to simulate any illumination conditions: direct sunlight, overcast sky, time of day, and geographic location instantly.

To extract as much image data as possible from a collected signal, it is useful to have roughly constant signal-to-noise ratio throughout the spectral range of interest. Unfortunately, a nonuniform response often results as signals from some spectral regions collected less efficiently. This is due to a combination of factors, including signal source, the system used to gather the signal, and the detector. A good example is the typical silicon detector array in the UV/blue, where their efficiency is several times lower than in red or near-IR. A source that produces more light in the UV/blue region can provide compensation so that the overall system response remains approximately flat (see Fig. 3).A natural extension of having a custom spectral profile for a specific system response is to adapt the illumination to the response of the sample. By adjusting the spectral profile of the illumination, the system response can be flattened regardless of the absorption by the sample, thus increasing the dynamic range for spectral regions with lower throughput.

Measuring plant response to sunlight helps improve our understanding of the important wavelengths needed to improve yield and reduce power consumption (by using only the wavelengths needed). In this case, a more flexible spectral profile is needed to test by increasing or decreasing different wavelengths and measuring the plant response. An 18-emitter light engine, with emitters from 365 to 680 nm, enables detailed and rapid analysis of optimal illumination conditions for plant growth.

The ability to combine multiple LED emitters to generate a uniform and stable spectral profile and to adapt that profile to specific conditions provides flexibility for a wide range of illumination and calibration applications. Such light engines can be easily integrated into existing systems without the need for major modifications, resulting in improved performance and dynamic range.

Paul Fournier is VP of Engineering and Rafal Pawluczyk is CTO, both at FiberTech Optica, Kitchener, ON, Canada; e-mail: [email protected]; https://fibertech-optica.com.