Frequency-comb Sources: One microresonator-based soliton comb replaces multiple WDM lasers

Microresonator-based optical frequency combs can cover broad wavelength regions in the electromagnetic spectrum. While pulsed laser sources (such as mode-locked lasers) can excite very short optical pulses called solitons that maintain their shape while traveling in a waveguide such as an optical fiber, dissipative Kerr solitons (DKSs) generated in microresonators were not realized until 2013. Since then, milestone experimental demonstrations have used DKS sources in dual-comb spectroscopy, exoplanet research, lidar, and even optical communications.

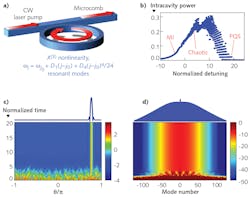

Researchers at the University of California, Riverside (UCR) and OEwaves (Pasadena, CA) have now improved upon DKS technology by predicting a new class of pulses supported by optical microresonators called dissipative pure quartic solitons (PQSs).1 While the standard microcomb DKSs have a hyperbolic secant shape, PQSs have an almost Gaussian profile with very small power variation when going from one tooth of the microcomb to the next (see figure). Compared to DKS formation, conversion of the continuous-wave (CW) pump power to the different frequencies of a PQS microcomb is a more-efficient process. Paired with their spectral power uniformity, this makes CW-pumped PQS sources a viable replacement for wavelength-division multiplexing (WDM) lasers for optical communications.

PQS architecture

Unlike creation of PQSs in photonic crystal waveguides through pumping by relatively high-power mode-locked lasers, the microresonator-based dissipative PQSs appear spontaneously in a microresonator using a modest-power CW laser pump. Considering the physical properties of the microresonator material platform and shape, the CW laser parameters needed to produce PQS pulse trains can be determined.

The key distinction between microresonator-based DKSs and PQSs, however, lies in the dispersion properties of the host resonator. DKS pulses rely on dominant second-order group velocity dispersion (GVD) of the resonator. As a rule of thumb, smaller GVD parameters at the pumping frequency result in a shorter pulse and, correspondingly, a wider comb in the frequency domain. Yet, dispersion cannot and should not completely vanish, and must exist to balance nonlinearity and make robust self-sustaining pulses—that is, solitons.

Microresonator dispersion engineering has been extensively studied in the microcomb community. But nobody had looked at the extreme case where second- and third-order GVD coefficients vanish and the fourth-order dispersion coefficient becomes dominant. In this case, not only can stable short pulses be generated, but they will offer significant advantages over DKSs. Evidence in the published literature shows that achieving the required dispersion profile is not only possible, but rather simple.

To find the width and peak power of PQS pulses in terms of experimentally relevant quantities such as the power of the external pump and the optical properties of the microresonator, the researchers used a Lagrangian variational approach. They also found a so-called scaling rule that connects the width of the pulse to its energy, predicting that when pulse width decreases, its energy increases much more rapidly for PQSs than for DKSs.

“Currently, for a 16-channel WDM device, 16 distinct CW lasers are used,” says Hossein Taheri, assistant research professor at UCR. “With flat-top power-efficient microcombs, all those lasers can be replaced by a single laser pulse on a chip-scale nonlinear microresonator—an ideal scenario for meeting the exacting requirements placed on modern datacenters. We expect power-efficient flat-top PQS microcombs to also be useful for spectroscopy and quantum optical applications.”

REFERENCE

1. H. Taheri and A. B. Matsko, Opt. Lett., 44, 12, 3086–3089 (Jun. 15, 2019).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.