Electrically pumped organic diode laser comes to fruition

The long quest for an electrically pumped organic semiconductor diode may be over after a series of false alarms stretching back two decades. Now, a team led by Chihaya Adachi at Kyushu University (Fukuoka, Japan) reports narrowline blue laser emission very sensitive to properties of distributed-feedback structures from multiple devices at threshold-current densities near 1 kW per square centimeter—a big advance in a field that had been taking much smaller steps toward this goal.1

High threshold currents are considered strong evidence of laser emission. So are clear threshold behavior, line narrowing, and strong sensitivity to modifications of the laser cavity, says Chris Giebink of Pennsylvania State University (University Park, PA), a veteran researcher in the field who was not involved in the study. The results surprised him, but after looking at the paper, he says the evidence is strong that “they may really have done it.”

Observations of electroluminescence from organic compounds dates back to the 1950s, but the first practical organic LEDs (OLEDs) date from 1987, and this technology has been widely used in color displays. The economics of OLEDs led to early hope for inexpensive organic diode lasers, but that changed after mass production of inorganic diode lasers drove down their prices. One main interest in organic diode lasers now is for providing colors not available from inorganic diode lasers, particularly in the green and yellow, where narrow-line laser emission could provide fully saturated colors and more attractive displays. Another is for deposition on flexible substrates or other substrates that work poorly for inorganic diodes.

Optical pumping proved successful for organic semiconductor lasers, and development of low-threshold distributed-feedback cavities allowed for compact and inexpensive organic optically pumped semiconductor lasers, similar to inorganic OPSLs. But the ultimate goal has been to develop electrically pumped organic diode lasers for integration with other optoelectronics and for applications in spectroscopy, medical devices, displays, and LiFi (light fidelity) optical networks, wrote Atula S. D. Sandanayka and colleagues in Applied Physics Express.

This proved to be a very tough challenge. It also was a very tempting target for now-infamous physics fraudster Jan Hendrik Schön, who in early 2000 claimed to have made an electrically pumped organic diode laser at Bell Labs. Exposure of his fraud made other researchers “much more suspicious of any new claims of organic electrical lasing,” says Jean-Charles Ribierre of the Kyushu group. Other early reports of electrically powered organic laser diodes mistook other phenomena for lasing, leading Ifor Samuel, Ebinazar Namdas, and Graham Turnbull to warn that anyone claiming laser action should have evidence of a sharp laser threshold, spectral changes above the emission threshold, beam coherence, polarization, and spatial profiles of the emitted light. Later reports also proved unconvincing, Ribierre says, including one that Laser Focus World published in 2017: “Electrically pumped organic laser diode has low threshold current density” (see http://bit.ly/OLaserDiode), based on a report in Science Bulletin2 by scientists at the Chinese Academy of Sciences (Changchun, China) that reported an unrealistically low threshold of milliamperes per square centimeter.

The organic compound is the key

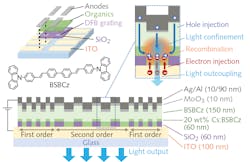

Years of research by many groups have produced gradual progress in overcoming the many obstacles to electrically pumping organic semiconductor lasers, so the new report seemed a surprisingly big step to Giebink. Ribierre says the key to success is that “we are the first group to overcome the final obstacle of getting all the parts to work together and actually achieve lasing.” The structure they used is similar to those used in conventional OLEDs, but uses films of BSBCz (a compound properly called 4,4’-bis[(N-carbazole)styryl]biphenyl) both as the gain medium and as the distributed-feedback (DFB) resonator. This compound has an exceptionally low laser threshold for optical pumping, a high optical gain, and no triplet absorption, which combine to permit continuous-wave (CW) operation of the electrically pumped laser.

The structure of the device is deposited on glass, starting with a layer of silica sputtered on indium tin oxide, to create a DFB structure 30 µm wide and 90 µm long (see figure). The organic layers and a conducting layer were applied on top of that. A crucial step will be for other groups to reproduce its performance. “It may be premature to celebrate victory, but it certainly looks promising,” says Giebink.

The Kyushu group is looking to develop other materials with similar or better properties to BSBCz and are clearly optimistic. Adachi, Ribierre, Fatima Bencheikh, and Takashi Fujihara of the Kyushu group early this year formed a startup, called Koala Tech, to produce the electrically powered organic diode lasers, which they plan to integrate into OLED and organic electronic systems.

REFERENCES

1. A. S. D. Sandanayaka et al., Appl. Phys. Express (2019); https://doi.org/10.7567/1882-0786/ab1b90.

2. J. Lin et al., Sci. Bull. (2017); https://doi.org/10.1016/j.scib.2017.12.010.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.