Next-gen laser welding: Innovations and trends

During the past decade, laser welding has undergone a significant evolution, driven by rapid advances in laser sources, control systems, and automation technologies. Once limited to specialized applications, laser welding is now a mainstream manufacturing technique for automotive, aerospace, electronics, and medical devices. The advantages of this tool are clear: Local energy input and contactless processing of a wide variety of metals, material thicknesses, and seam geometries.

Several developments are driving this evolution. The introduction of high-brightness fiber lasers and ultrafast lasers for microwelding dramatically improved weld quality, speed, and precision, while reducing thermal distortion and post-processing needs. These sources, particularly fiber lasers, are also significantly less expensive now, which makes the laser process more accessible for a wide range of industries. And different wavelengths are available today, which enables better absorption of radiation for certain materials—at least at room temperature.

Improvements are also being made for the rest of laser welding components. Processing heads, especially the optics built into these tools, are increasingly reliable and transmissive. At power levels commonly used for laser beam welding, thermal focus shift is no longer an issue. This is due, in part, to significantly higher-quality optical coatings. In parallel, the integration of robotics, AI, and digital twin technologies enabled smarter, more flexible production lines. These innovations not only expanded the range of materials and geometries that can be reliably welded but also reduced costs and improved process scalability, which makes laser welding a cornerstone of modern, high-performance manufacturing.

Laser welding strategies for e-mobility

The transition to e-mobility significantly changed the design of powertrain assemblies and components. One interesting case is the hairpin motor, which is an electric motor with stator winding hairpins instead of round wires. Hairpins are rectangular and large compared to wires, and their rectangular shape allows for a better fill factor, which makes the copper winding is ~20% more efficient. This design has been adapted by most of automotive OEM and suppliers, and requires laser welding of the windings’ open ends.

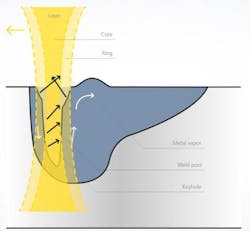

For this application, the typical weld sequence uses a split strategy with a sequential melting of the pins and a larger connecting trajectory to generate a melt pearl atop the pins. To improve final welding quality, TRUMPF developed the BrightLine Weld technology (see Fig. 1). Compared to a standard laser design, the beam delivery fiber is composed of a hollow ring fiber with an inserted core fiber to supply a superimposed beam profile to the workpiece. By using an optical beam wedge on the fiber entry side, distribution of laser power to the respective fibers can be freely adjusted. The effects on the process, especially copper joining, result in significantly decreased spattering and porosity formation. The ratio core (40%) and ring (60%)—tied adjustment—enables the lowest emission of spatters and formation of porosities. This optimizes weld quality and laser power can be used to the full nominal power level. Typically, 6- or 8-kW disk lasers are used in hairpin welding to enable the deep penetration welding regime necessary to generate the melt volume within microsecond-range processing times. The latter mainly depend on the wire cross sections used, which reach from 25 milliseconds (ms) up to 200 ms for single pin pairs of common products (see Fig. 2).

Benefits of beam shaping

Beam shaping is bringing about truly disruptive changes right now, and will continue to do so in the future. Beam shaping enables tailoring spatial and temporal distribution of laser energy to match specific material and joint requirements. Traditional Gaussian beams may not always deliver the ideal energy profile for consistent and defect-free welds, especially when dealing with complex geometries, highly reflective materials, or dissimilar metal combinations.

Modifying the beam shape offers advantages, such as fewer spatters, welding faster, better control of energy dissipation in the joining partners, and stabilizing the keyhole. In the future, it will be essential to precisely describe the quality of an application-specific intensity distribution in terms of distribution “sharpness,” the depth of field, dimensional accuracy, efficiency, and more. Beam shaping is undoubtedly the future of laser material processing.

Several approaches to implement beam shaping for laser welding applications exist. The company Cailabs offers a multiplane light conversion (MPLC) solution. Their approach transforms standard Gaussian beams into complex, application-specific profiles such as top-hat, ring-mode, multispot patterns—without loss of beam quality or power. Advanced beam control significantly enhances weld consistency, reduces thermal distortion, and minimizes defects such as spatter, porosity, and cracking, especially for challenging materials. The company’s beam shaping modules are compact, passive, and fully compatible with industrial laser systems, including the laser heads from Precitec. The Cailabs CANUNDA beam shaping system meets the demands of industrial laser applications, including the growing e-mobility market, regardless of the processing optics manufacturer (see Fig. 3).

A solution by Robust AO, called “Zwobbel” technology, enables beam wobbling within the z-direction in frequencies up to 2000 Hz for dynamic beam shaping. In beam wobbling, the laser beam is intentionally moved in a controlled, oscillating pattern while it travels along the main welding path. This movement is superimposed onto the linear motion of the laser to create a dynamic energy distribution that can be precisely tuned to the material and joint geometry. It’s used as a 90° deflection mirror and can hold the focus within the scanning plane as it dynamically changes its shape upon activation.

Axial dynamic beam forming with Zwobbel technology was analyzed for its performance reducing porosity and spatter formation during laser welding of aluminum alloys. A comparison with a reference test series devoid of beam oscillation (process with static focal position) revealed a substantial decrease in porosity, particularly within the root area. A more homogeneous welding depth was also achieved, and the fluctuation range of the welding depth was reduced by ~45%. Results indicate the axial dynamic beam shaping process reduces intensity peaks within the root area and also localizes material evaporation. A series of supplementary tests explored spray behavior and the potential for targeted influencing of the weld seam geometry and found high oscillation frequencies are associated with a significant reduction in spatter formation, which suggests a widening of the keyhole. Cross-section analyses showed the change within the melt pool and resulting modifications to the weld seam geometry: While maintaining the welding depth, the seam width in the cover layer area increased by 25%, and in the root area by as much as 34%, in comparison with the welding process without an oscillating beam. Through these tests, Robust AO showed the efficacy of axial dynamic beam shaping to enhance the quality of weld seams (see Fig. 4).

New solutions for process monitoring

As the demand for precision and efficiency in laser processing grows, manufacturers struggle to maintain quality assurance with outdated methods. Manual inspections and conventional monitoring systems often lead to high error rates, increased scrap, production downtimes, and inefficient workflows. Common production challenges include unstable processes, high scrap rates, undetected process deviations, or lack of traceability. Automated, intelligent, and real-time monitoring systems are essential for improving process reliability, reducing waste, and ensuring traceable, high-quality production.

The world of process monitoring sensors based on photonics has seen dramatic advances of improved sensitivity and higher sampling rates. For example, the company 4D Photonics developed a 4D.TWO sensor, a highly efficient, software-adjustable solution for laser process monitoring with minimal on-site setup. This sensor captures the full spectral range in visible (VIS) and near-infrared (NIR) light, using 16 channels each, along with three broadband channels for VIS, NIR, and back reflection. These are recorded at sampling rates of up to 100 kHz to enable detailed real-time analysis of laser processes and detection of anomalies such as cracks, pores, and spatter.

4D Photonics’ “lossless technology” enables seamless, continuous data acquisition using two alternating evaluation units. This design eliminates dead times and ensures no monitoring blind spots—even at high welding speeds (≥1 m/s for bipolar plate welding). Despite operating at a lower sampling rate, the system detects even minor deviations with precision and significantly reduces data volume without compromising accuracy. The 4D.TWO sensor features a 9-axis motion tracker to detect path deviations in robotic systems and also records temperature, humidity, and air pressure. Combined with the 4D.watcher software, users can classify fault types by creating multiple “combi channels” linked to different root causes. This streamlines fault identification and shortens recovery time after production issues.

Laser welding as a service

The Manufacturing as a Service (MaaS) concept allows companies to access advanced manufacturing capabilities on demand. MaaS platforms leverage cloud-based systems, digital twins, and distributed production networks to offer flexible, scalable, and location-independent manufacturing solutions. Laser welding, with its high precision, automation compatibility, and versatility across materials, fits seamlessly into this model. Service providers can offer remote programming, real-time monitoring, and quality control of laser welding operations through digital interfaces, which makes it possible to deploy complex joining processes in a highly efficient, pay-per-use manner. This democratization of access to cutting-edge manufacturing technologies like laser welding supports rapid prototyping, customization, and just-in-time production to align perfectly with the needs of agile, modern supply chains.

The EU project Lasers4MaaS (https://lasers4maas.eu) is at the forefront of transforming modern manufacturing. By leveraging dynamic laser beam shaping and AI-driven manufacturing, their cutting-edge digital manufacturing platform enables on-demand, sustainable, and cost-effective production. The workflow starts with seamless integration of design and production data via a digital platform to ensure all systems are aligned. Once the data exchange is finished, the dynamic beam shaping technology customizes laser operations in real time to deliver precise and efficient material processing tailored to specific applications. During production, AI continuously monitors key parameters to provide immediate feedback and optimize process performance, and digital twins and predictive analytics ensure products meet stringent quality standards, while life cycle assessments evaluate environmental impact. Different insights from production data will be fed back into the system for ongoing refinement and enhanced efficiency for future operations.

Lasers4MaaS is poised to revolutionize industries, such as the automotive sector, where flexibility and productivity drive innovation in laser welding; aerospace, which benefits from high-precision custom manufacturing; food packaging, where product quality is paramount; and renewable energy sectors, like hydrogen and fusion energy, where advanced laser solutions support the transition to a cleaner and greener future. By addressing the unique challenges of each industry, Lasers4MaaS will accelerate the adoption of smart, sustainable, and decentralized manufacturing practices. Its offering of on-demand access to advanced laser systems enables flexible and scalable manufacturing solutions without the need for large upfront investment.

Related Article

About the Author

Antonio Castelo

Antonio Castelo is Technology Manager for Bio-Medical and Lasers at the European Photonics Industry Consortium (EPIC).