Laser sintering method simplifies ultrahigh-temperature ceramics

A new twist on sintering developed by North Carolina State University engineers led by Cheryl Xu, a professor of mechanical and aerospace engineering, taps lasers to turn raw materials—in either liquid or powder form—into ceramic materials with potential for space, defense, and nuclear power applications that must withstand ultrahigh temperatures within extreme environments (see video).

Unlike traditional sintering that involves a furnace that can hit in excess of 2200°C, the laser approach developed by Xu’s group doesn’t require a furnace, is faster, simpler, and requires much less energy. Instead, their laser sintering method taps the inert environment of a vacuum chamber and additive manufacturing equipment.

“We were inspired by the need for better ways to manufacture ceramics that can withstand the extreme environments of hypersonic flight, space exploration, and advanced energy systems,” Xu says. “Materials like hafnium carbide (HfC) are ideal for these applications because of their extraordinary temperature resistance, but traditional manufacturing is extremely slow, energy-intensive, and inflexible. We wondered: Can we use laser energy to radically simplify the process?”

SLRP

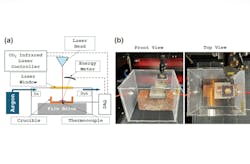

The team’s new method is called “Selective Laser Reaction Pyrolysis (SLRP),” and it starts out by applying a thin film of polymer precursor onto a substrate or putting it into a mold. A 120-W laser scans the surface and heats the material to initiate a dual transformation that crosslinks the polymer chains, and then pyrolyzes the solid into HfC ceramic.

“We use a CO2 infrared laser (10.6-µm wavelength) to selectively heat a liquid polymer precursor of HfC,” explains Xu. “The laser delivers localized thermal energy, which rapidly raises the temperature above 2000°C within seconds. This triggers the polymer crosslinking and pyrolysis within a single step and transforms the liquid into nanocrystalline ceramic. The process is highly controllable and efficient, thanks to localized photothermal conversion, which lets us precisely fabricate coatings for 3D structures.”

This entire conversion from liquid to crystalline HfC occurs within minutes and “eliminates the need for large furnaces,” Xu says. “We can also coat delicate materials like carbon-fiber composites without damaging them.”

Paradigm shift

This work is a paradigm shift for fabricating ultrahigh-temperature ceramics. “Traditional furnace sintering takes hours to days and consumes huge amounts of energy,” says Xu. “Our laser method works within minutes and is localized, so we don’t waste energy heating entire components. It also enables complex geometries and digital manufacturing—which brings the agility of additive manufacturing to this class of extreme materials.”

Of course, there were a few hurdles involved. “Controlling energy absorption and avoiding defects were both challenging,” says Xu. “The polymer chemistry needed to be optimized to ensure uniform conversion, and we experimented with thermal and photo-activators to fine-tune the process. Managing heat flow when coating conductive composites like C/C requires careful thermal engineering to ensure good bonding and phase purity.”

One of the most memorable moments for the team occurred when they saw pure-phase HfC, with excellent nanocrystalline structure, produced from a simple liquid film using only the laser—without a furnace.

“Another exciting result was successfully coating carbon-carbon composites with strongly adherent HfC layers, which isn’t feasible via conventional sintering,” says Xu. “Seeing it work for the first time was exhilarating because we overcame a long-standing manufacturing bottleneck with a laser.”

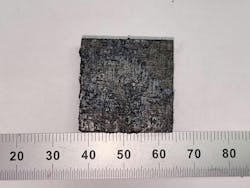

The team put it to the “torch test” to study the flame resistance of samples coated with HfC using their laser sintering method and blasted it with a flame from a propane torch for five minutes with a maximum temperature of ~1900°C. “The sample showed relatively low damage to the carbon substrate after exposure to the flame, which indicates the oxidation resistance of the ultrahigh-temperature coating at high temperatures,” says Xu.

As far as a timeline, the team has already demonstrated high-quality coatings and powder synthesis. “With further engineering, it could transition to aerospace or defense coatings within two to five years. We’re actively looking for partners to help scale and commercialize our method,” she adds.

Seeking funding and collaboration partners

Xu and her team are now exploring several directions: Extending the process to other ultrahigh-temperature ceramics such as zirconium carbide (ZrC) and tantalum carbide (TaC); developing 3D printing approaches to fabricate fully additively manufactured UHTC components; and creating compositionally graded materials in which ceramic properties can vary within a part, which enables advanced thermal protection and multifunctional materials.

“Critically, we’re also actively seeking funding and collaboration partners from both public and private sectors to help transition this technology to practical applications for aerospace, defense, energy, and other industries,” she says.

If you’d like to reach out: [email protected].

FURTHER READING

S. Rajpoot, K. N. Vinod, T. Fang, and C. Xu, J. Am. Chem. Soc. (May 14, 2025); https://doi.org/10.1111/jace.20650.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.