Despite the pandemic and an ongoing world economic crisis, caused in part by the Russian-Ukrainian conflict and climate change, laser material processing equipment investments across Chile have not ceased. Chile has been hit hard by inflation (12% since 2022) and depreciation of its local currency (30%). Uncertainty due to the approval of a new constitution text that will take place in November 2023 has idled foreign investment projects until the new rules are established in case the new constitution text is finally approved. On the contrary, the process of modifying the carta magna will continue however stretching this uncertainty scenario.

Laser system investments

Even with the uncertain environment, local investment from small- and medium-sized companies regarding the acquisition of new laser equipment has been quite significant. Small-size companies, such as DTI Dental and Beraudent, have been acquiring small 100 W laser powder-bed fusion (L-PBF) units from Concept Laser (now a GE company) for dental restoration components (crowns and bridges) mainly working on cobalt chromium (CrCo) metal. Two other selective laser melting units have arrived: one at LEiTAT research center (Catalunya, Spain), a Renishaw 400 W unit, and the other to Pontificia Universidad Católica (PUC) Mechanical and Metallurgical Department, a GE-Concept Laser MLab 200R with a 200 W fiber laser-driven unit with reactive powder handling capability (see Fig. 1).

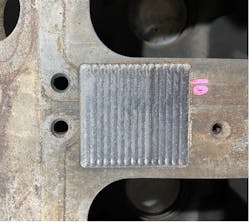

More remarkable is the recent acquisition by Power Train Technologies (PTT), a company devoted to remanufacturing heavy metal components, of a laser cladding system for remanufacturing diesel engine and truck components mainly used in the mining sites. It consists of a 4 kW continuous-wave (CW) Laserline red diode laser and a cladding head of the same brand, a GTV powder feeder system, a Kuka robot arm (3 mts span), and a 7 m length CNC lathe (see Fig. 2). The integration of the system was done locally and the main application will be to recover cast steel engine blocks and other mining components by cladding ferrochromium (Fe-Cr) and nickel (Ni) alloy followed by precision machining (see Fig. 3). Their powder supplier is Höganäs from Sweden. According to PTT’s Director and CEO, Mariano Schroeder, “Laser metal deposition opens a great opportunity for the circular economy and the reduction of the carbon footprint particularly in the mining sector.”The PUC laser lab has also acquired three new laser units: a 3 kW CW fiber laser, a quasi-CW 150/1500 W fiber laser (both from MaxPhotonics [China]), and a nanosecond pulsed fiber laser from Sintec (Singapore). The research group has also endeavored with the development of a polar L-PBF unit using a 300 W CW IPG Photonics fiber laser and galvo scanner head from Sintec. This latter system has reached some milestones; e.g., 60 µm layer thickness. However, it has not been absent from its complexities like thermal management and layer delamination.

Several high-power CO2 and fiber lasers have entered the metal sheet cutting market: LEMACO with over 20 years of presence, leading the way with three Bystronic laser cutters and DiFierro with a 3.2 kW TRUMPF CO2 laser unit. At least 10 other companies in Santiago have laser metal cutters in-house for services or self-production: Pardo, Oppici, Teknip, MAD, AlphaMetal, DualFix, Sinsay, Metalux, CARE, and Lasermet, to name a few. Recently at the EXPOMIN international mining exhibition and fair, Chinese company Bodor Laser presented its 12 kW fiber laser scanning cutting machine, able to cut over 30 mm of low-carbon steel with a 30 m long table.

A success story

Undoubtedly, all this is good news pushing forward the remanufacturing industry, medical sector, and education and research in the field of laser technology applications.

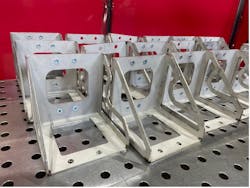

On the other hand, Reborn Electric Motors, a young company based in Rancagua (100 km south of Santiago) that manufactures electrical buses for transportation inside mining sites, uses laser-cut parts from LEMACO for many of the support angles and enclosures where the electronic board and the lithium iron phosphate batteries (LIPBs) are sheltered (see Fig. 4). CEO Felipe Cevallos explains, “Laser cutting allows fast prototyping of new metal components and accurate fabrication from CAD design.”Reborn has so far produced almost 100 buses for CODELCO, one of the largest copper mining companies in the world, which is committed to reducing its carbon footprint. Currently, the bus chassis is made in Brazil, but it is retrofitted in Chile to work with an electric motor and the LIPB packages are imported from China; the body is designed in Chile and manufactured by Marco Polo in Brazil. However, their plans are to expand and manufacture a chassis in Chile and export their complete bus production to Brazil starting soon.

Laser technology is strongly present in a small and faraway country like Chile. It is expected that the reindustrialization processes the country must embark on despite its extremely open market economy, should increase further the presence of laser technologies in industry and academia soon.

About the Author

Jorge Ramos-Grez

Professor, Pontifical Catholic University of Chile (PUC) School of Engineering

Jorge Ramos-Grez, Ph.D., is a full professor from the School of Engineering at Pontifical Catholic University of Chile (PUC; Santiago, Chile), and is part of DICTUC SA, an engineering consulting company from the same university. He has devoted his entire academic career to teaching and fostering laser industrial applications in Chile and the South American region.