Laser materials processing uses a laser-generated focused light beam to cut, weld, drill, mark, engrave, and surface-structure a wide range of materials—from metals to plastics, ceramics, glasses, and organics. Laser light possesses special characteristics that are highly focusable and specifically matched to the materials in question, which lend themselves to precision manufacturing.

Automation combined with industrial laser technology has led to the processing of many complex part geometries and materials that just several years ago would have been considered impossible to process efficiently by laser methods. Recent examples include large-scale texturing of polymer- and metal-based parts with developable 3D freeform surfaces such as automobile dashboards and external bumpers or other parts in the meter-plus size range (see Fig. 1).

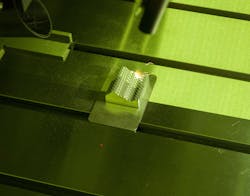

Other examples include mechanically delicate parts at the opposite end of the scale, such as microwires and coils used in medical devices for embolizing small vessels in the brain when stroke victims experience aneurysms. These devices are made from sensitive wire-wound materials such as platinum and Nitinol, and are on the scale of low tens of microns in diameter.

First steps

The laser source is only the first building block of the solution for processing these types of complex products. It is considered the heart of the system and selected to give the desired processing effect when matched to the optical absorption and thermal properties of the material at the required quality and throughput.

Laser sources span a range of technologies, from semiconductor lasers to gas, fiber, and solid-state lasers. They all bring their own unique characteristics and are selected according to the parts to be processed. Mainstream processes on these parts encompass laser marking, engraving, structuring, cutting, drilling, welding, and surface treatment. Many application variables should be taken into account to identify the laser source with the best balance of performance, quality, throughput, and cost—and even more so on unforgiving and delicate parts. This is the work of application laboratories using the identical laser source configuration as will be finally integrated into a system. It is important to use the exact configuration early to avoid repeating costly and lengthy development work later in the machine build.

Integrated solutions

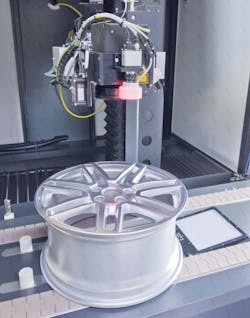

A solution for laser materials processing requires a machine system (see Fig. 2). The solution to a laser-based manufacturing challenge completely depends on the successful marriage of automation, hardware components, vision systems, optics, laser beam delivery, software, databases, and laser sources into the system. The integration of a laser source into a laser system solution for a complex part is a very specialized task, which requires significant technological expertise in the organization across a broad range of subjects. This is especially the case when consumer products such as automotive and healthcare are the target markets. Relevant safety, mechanical and electrical standards, and regulatory compliance must be adhered to, ensuring constant high quality.State-of-the-art options

Laser structuring, texturing, marking, and engraving typically required lasers delivering short, sharp pulses and often use fiber lasers as the generating technology. These laser sources are connected to galvanometer scanning heads (galvos), which steer the laser beam dynamically over small processing areas such as 110 × 100 mm with standard optics, and on a 2D basis for flat parts. For a larger 3D component such as a complicated automotive alloy wheel geometry that requires marking with tiny features and intricate detail, this approach is cumbersome. It is often impossible because it requires multiple step-index movements and alignments to process the entire surface at the required resolution. Using the conventional method, not all segments of the pattern and design are seamlessly connected.

This problem is solved by introducing a laser system that can wrap a 2D CAD design over a 3D developable surface up to 2000 × 2000 mm in size, without any indexing movements of the workpiece or laser head during the procedure. The process is carried out in one continuous, uninterrupted operation. At the same time, the system maintains a small laser spot size over the entire processing area to preserve high resolution, facilitating the production of tiny features. These systems quickly gain the interest of manufacturing engineers and designers. Commonly referred to as large-field removal systems, they cut down processing steps and reduce a complex part processing to a relatively easy one (see Fig. 3).Final steps

Now that a solution has been identified for laser machining a large 3D part in one continuous uninterrupted process, next questions may include:

- How is it possible to locate exactly where on this complex part the features are going to be processed given the part tolerances?

- Is the part in the correct orientation for processing?

- How can this be verified?

The vision system will also report offsets for the processing areas of interest, and can report height and depth information about the parts. The lighting and contrast achievable are key determinants in the success of handling vision on complex parts, as are the accuracy and repeatability of the positioning system to start the process at the right spot. The same system can be used to optically recognize the part after processing and to perform quality checks against a known gold standard for the process.

Often, these integrated laser system solutions become more complex in the sub-100-µm size region. These smaller parts can result in the laser vision systems working on the limits of the camera resolution, as well as the mechanical axes and parts-handling devices working on the limits of their repeatability and ability to stop where required. The laser sources in this case are frequently working on the limits of their lower power control to ensure a repeatable and uniform process. For example, finding the position of a platinum or Nitinol wire of 50 to 100 µm in diameter and successfully welding it to another wire in close proximity is a challenging task requiring careful integration of the entire system.

The initial starting point for a project on a complex part is a very clear understanding of the user requirement specifications. Small changes in the specifications such as materials and part geometries or quality constraints will have a major influence on machine design.

About the Author

Jonathan Magee

Managing Director, ACSYS Lasertechnik UK Ltd

Jonathan Magee is Managing Director at ACSYS Lasertechnik UK Ltd (Coventry, UK).