Time/energy sharing for fiber beam ultrafast lasers

Beam sharing—distributing the beam of a laser—is state of the art for industrial solid-state lasers with fiber beam delivery. There are two methods of beam sharing: time sharing and energy sharing.

Time sharing means switching the beam of a single laser source alternatively between different processes or workstations. This allows a higher laser system utilization while making use of a single laser source, since typically the laser-on-time of a single application is only within the range of 10 to 20% of the available time.

Energy sharing is used for splitting the laser beam simultaneously for several applications. Whether equal or variable, the splitting ratio does not need to be limited to two laser beams. Application examples include simultaneous processing of multiple components in parallel when enough laser power is available; processing components from different orientations to achieve identical results; or preventing unequal thermal distortions.

Ultimately, beam sharing enables a higher use of the available laser energy, while also enabling cost reduction by saving on capital expenditures. Beam sharing has been a substantial contributor to the successful worldwide acceptance of industrial solid-state lasers over lamp-pumped systems as well as disk, fiber, and diode lasers.

Until the introduction of fiber-based beam delivery (FBD) for ultrafast lasers, the laser beam was delivered directly via free-space optics. Using hollow-core fibers that guide the ultrafast pulses in air or vacuum, it is possible to overcome the damage barrier, which stops ultrafast pulses from being transmitted in step index glass fibers. At the same time, nonlinear effects such as dispersion and spectral broadening are strongly reduced and allow ultrafast pulses within the picosecond and femtosecond domain to be transmitted unaltered.

When using free-space transmission, one must manage and reduce beam path disturbances—resulting in laser placement near the workpiece. With fiber beam delivery available, the basic concept of laser integration can be changed. In this way, the request for time and energy sharing for short-pulse laser systems has also arisen.

Industrial solid-state systems using beam sharing are typically multimode lasers and require a far less stringent optomechanical tolerance management on the fiber beam delivery. Yet, fiber-beam-delivered ultrafast lasers require a very precise single-mode coupling into the microstructure of the hollow-core fiber. A stable coupling, while maintaining beam position tolerances at the fiber tip within a few microns and beam pointing variations within milliradians, is the prerequisite of successful fiber beam delivery.

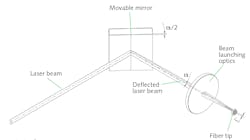

Beam sharing requires the introduction of optical elements into the beam path of a coupling unit, typically fixed for energy sharing and moving for time sharing. Maintaining the single-mode beam-coupling efficiency in the delicate fiber relates to microradian angular tolerances of the position of any moveable components responsible for beam deflection (see Fig. 1).

The main challenge is to design a beam deflection component capable of handling the tolerance requirements and maintaining this specification over the product lifetime, which can mean 10 to 100 million switching cycles under varying operating conditions.

System components

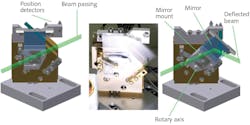

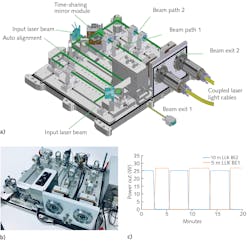

The key component of the time-sharing system is the time-sharing mirror module. The mirror for deflecting the beam is mounted on the motor-driven rotary axis in such a way that the final position of the mirror enables a repeatable position of the laser beam on the fiber tip (see Fig. 2). Additional redundant sensors allow for a secure retrieval of the current beam position and enable a safe laser environment.Figure 3a shows a two-way time-sharing system, which can couple the beam of one ultrafast laser alternatively to two different independent laser light cables. This system also incorporates beam stabilization that compensates for beam pointing variations during the use of the laser systems or thermal settling of the system. The optical setup is scalable to more output ports by adding additional time-sharing mirror modules, beam-launching optics, and laser light cables.

The time-sharing system has already been installed on a few occasions and coupling to a 100 W average-power femtosecond laser has been demonstrated. The coupling efficiency and the laser beam quality are not affected by the time-sharing system and equals the performance of a directly fiber-coupled ultrafast laser beam. Figure 3b shows the output power of a coupled 5-m-long and coupled 10-m ultrafast laser light cables with a coupling efficiency. For both cables, the system transmission is in excess of 90%. The longer cable showed an expected slightly lower transmission caused by the intrinsic losses of the microstructured hollow-core fiber.Fiber beam delivery systems for ultrafast lasers have now been augmented by the technological building-block beam sharing. The flexible sharing of the laser beam between different workstations and workpieces not only reduces the cost of the laser installation, but also allows for a redundant system architecture where a second laser light cable can be routed to the workstation, which is typically serviced by a dedicated laser source. In the event of a failure of one laser, they can easily service multiple workstations (albeit at a potentially increased overall cycle time).

The beam-sharing system is designed for the future implementation of full laser safety-compliant beam exit status indicators and a fiber continuity system so that the laser Class 4 environment can be restricted to the laser cell directly at the individual workpiece being processed.

The increasing power of industrial ultrafast laser systems and the use of beam sharing in fiber beam delivery enables more efficient operation of these high-power laser systems.

About the Author

Björn Wedel

Founder and CEO, PT Photonic Tools

Björn Wedel is founder and CEO of PT Photonic Tools (Berlin, Germany).