9.3 µm carbon dioxide laser cuts delicate designs in paper

Paper converting processes typically operate at very high speeds, with roll-to-roll machines sometimes reaching speeds of up to 400 m/min. Laser cutting is achieved by sublimation, so paper and card materials react well to the carbon dioxide (CO2) laser wavelength range with a cutting process that is fast and reliable with good-quality results.

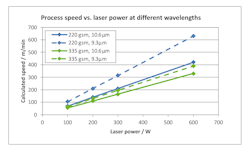

The graph shows paper cutting speed is directly proportional to the laser power, so doubling the process speed would usually need twice the power. It also demonstrates that the 9.3 µm wavelength can cut up to 20% faster than the 10.6 µm laser, depending on the composition and weight of the paper. Luxinar’s SR series and OEM 45iX sealed CO2 laser sources are recommended for these high-speed paper converting applications at the 9.3 µm wavelength.In addition, the laser process allows complex designs to be cut with ease and precision, and designs can be changed or modified with a minimum of fuss. The non-contact nature of the process means that delicate designs, such as those needed for greetings cards and fancy stationery, are not deformed or distorted during cutting.

The Luxinar (Kingston-upon-Hull, England) applications laboratory is equipped with CO2 lasers at both 10.6 and 9.3 µm wavelengths. The company is available for testing some paper or card samples of paper or cards; for further information about this application, please contact [email protected].

Luxinar manufactures sealed CO2 laser sources and, more recently, femtosecond laser sources. To date, the company has an installed base of over 20,000 lasers worldwide in industrial applications environments.

About the Author

David Belforte

Contributing Editor

David Belforte (1932-2023) was an internationally recognized authority on industrial laser materials processing and had been actively involved in this technology for more than 50 years. His consulting business, Belforte Associates, served clients interested in advanced manufacturing applications. David held degrees in Chemistry and Production Technology from Northeastern University (Boston, MA). As a researcher, he conducted basic studies in material synthesis for high-temperature applications and held increasingly important positions with companies involved with high-technology materials processing. He co-founded a company that introduced several firsts in advanced welding technology and equipment. David's career in lasers started with the commercialization of the first industrial solid-state laser and a compact CO2 laser for sheet-metal cutting. For several years, he led the development of very high power CO2 lasers for welding and surface treating applications. In addition to consulting, David was the Founder and Editor-in-Chief of Industrial Laser Solutions magazine (1986-2022) and contributed to other laser publications, including Laser Focus World. He retired from Laser Focus World in late June 2022.