Directed energy deposition: Applications and outlook

Directed energy deposition (DED) is perhaps the oldest example of fusion-based additive manufacturing. As early as 1925, the concept of using an electric arc for the fabrication of a 3D object was patented by the Westinghouse Corporation. Things have progressed a long way since 1925—but, in principle, today’s DED systems are not far removed from this early conception.

Modern laser DED systems are equipped with reliable laser sources, precise motion systems, and powerful computing capabilities. Coupled with CAD, process planning, and motion control software, these systems are used for a wide range of applications, including part production, feature addition, repair, and surface coatings.

Laser DED process and systems

Laser DED (L-DED) systems consist of three main components: a laser beam that delivers energy to form a melt pool atop a substrate; a feedstock delivery system that blows powder or injects wire into the melt pool; and a motion system that translates the laser beam and feedstock relative to substrate.

A decade ago, most L-DED systems employed CO2 or Nd:YAG laser systems. Today, nearly all commercial L-DED systems employ a fiber-delivered laser, with ytterbium-doped fiber lasers being the most common. Most of these systems operate with laser powers in the range of 200 to 1500 W, though much more powerful systems (on the order of 10 kW) are now commercially available. Though fiber lasers dominate, Nd:YAG disk lasers are also used, as are diode lasers.

Either metal powder or wire can be used as a feedstock material. In both cases, the introduction of feedstock into the melt is not trivial. Low-deposition rates of several grams per minute are common for low- to mid-power systems, while systems using kilowatt lasers can feed tens of grams per minute into the melt. A wide range of deposition heads (for example, coaxial or multi-nozzle) are available for powder delivery. Off-the-shelf heads are available for integration into custom configurations; in most cases, L-DED system manufacturers employ their own deposition head design.

To access tight geometries, systems used for repair applications are often equipped with a compact head that has steeply angled nozzles, relative to the underlying substrate. Other systems employ very shallow-angled nozzles to enable the deposition of overhangs. Still others are more concerned with minimizing the waist of the flowing powder stream—keeping the waist of the powder focus on the order of the laser beam spot size maximized the efficiency of captured powder. A frank assessment is that the lack of standardization in deposition head design leaves end users guessing at what may best suit their needs for a particular application.

As with powder delivery, there are also several varieties of wire delivery. Most commonly, a wire is inserted at a shallow angle into the front of the melt pool via a standard welding wire feeder and nozzle. Such an arrangement requires coordinating the position of the wire relative to the substrate translation direction. The wire must always be inserted near the front of the melt; otherwise, the operator risks freezing the wire in the rear solidifying region of the melt. However, there are systems that feed wire coaxial with the laser beam. For instance, the Fraunhofer Institute for Material and Beam Technology (Dresden, Germany) offers a deposition head that splits and directs the laser beam around and into a coaxially delivered wire. By enabling direction-agonistic deposition, coaxial wire feed systems overcome a major limitation of conventional wire-feed L-DED.

There are also many varieties of motion systems used for L-DED. The simplest machines employ a 3-axis linear stage system, where the substrate or deposition head move relative to one another. In the past several years, there has been an increase in the number of 4- and 5-axis systems, which enable rotation and/or tilt of the substrate or deposition head. Four-axis systems are particularly useful for repair of shafts, tubes, and other cylindrical components, such as the high-value Ti-6Al-4V shaft repair conducted on a modified Optomec LENS system (see Fig. 1). The use of robot arms, employing 6 axes or more in addition to tilt and rotation of the substrate, is also gaining popularity. Such systems enable the greatest freedom in part complexity and size, but still cannot match the accuracy and precision of traditional stage systems.

Commercial and emerging applications

In general, L-DED systems fall into one of two categories: multikilowatt systems for rapid, large-area additive manufacturing and lower power systems for precision repairs and feature addition. In the past several years, hybrid additive manufacturing systems, which couple L-DED with in situ CNC machining, have attempted to combine large-area additive manufacturing with precision—or at least rough—finishing.

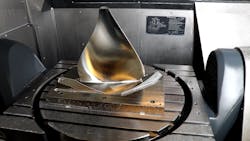

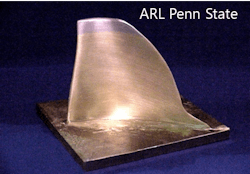

By far, the most common application of L-DED is for repair of high-value components. In many cases, the cost of the repair is orders of magnitude less than the cost of part replacement. Consider the case of the repair of a nickel alloy turbine blade, where repair typically requires the addition of a handful of layers atop a machined surface, followed by post-process finishing. A several-inches-wide blade may take tens of minutes to repair; in this time, tens of grams of powder are consumed, with the total cost of both powder and labor likely to be on the order of tens to hundreds of dollars per blade—this is much less than the cost of a new blade. For such applications, a system employing a several-hundred-watt laser with a compact powder feeding head and a 4- or 5-axis motion systems is ideal. Figure 2 shows a L-DED-repaired Inconel blade that has not been finish-machined.Outlook

Despite being one of the oldest additive manufacturing technologies, L-DED is still relevant and growing in utility. Today’s systems offer many configuration options, including laser type, laser power, feedstock type, motion control, and the availability of in situ machining. This enables a wide range of applications, including part repair, feature addition, and full deposition of freestanding structures.

About the Author

Abdalla R. Nassar

Head of the Process Physics, Analytics, and Engineering Department, Pennsylvania State University Applied Research Laboratory

Dr. Abdalla R. Nassar is Head of the Process Physics, Analytics, and Engineering Department at the Pennsylvania State University Applied Research Laboratory (University Park, PA).