Laser welding process for plastics offers improved reliability, efficiency

Evosys Laser (Erlangen, Germany) recently started offering a new, patented welding process that leads to a significant increase in efficiency. With so-called Advanced Quasi-Simultaneous Welding (AQW), selected plastics can be processed even more economically.

Laser welding of plastics is already an extremely economical joining process in its usual form. It has been steadily gaining in importance for years and is used currently in almost all industries. Recognizing this, the Evosys Laser team is constantly tinkering to further improve the reliability and efficiency of laser welding. With the new AQW process, this has now been achieved for selected plastics.

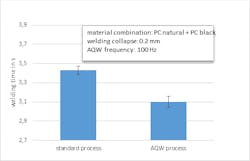

Numerous test series have shown that welding times can be significantly reduced in some cases. The process makes use of the absorption properties of the plastics and combines two different wavelengths that are alternately guided over the welding zone in a controllable pattern. Experience with AQW shows an improvement in process time compared to the standard process with only one laser source. The new process can be applied to materials such as polycarbonate (PC), but other common plastics are also conceivable in the future.Parallel to the patent granting process, the necessary system technology for the AQW process was developed and optimized for series use. “Our customers can test the process extensively in our Technical Center at any time and use it later for their series production,” explains Frank Brunnecker, managing partner of Evosys Laser.