Laser micromachining platform has use in small-component prototyping

BOLD Laser Automation (Bedford, NH) has introduced its LMM500 series of laser micromachining tools for early-stage medical (catheters/stents) and fluidic device manufacturers (3D printing/inkjet printing).

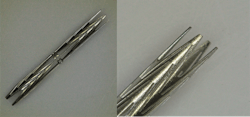

The LMM550 laser-cuts precisely to produce small tube-based products such as stents and can switch to selective material removal techniques for drilling or milling microfluidic parts or even microelectronics substrates. The standard LMM-550G is a galvo-driven micromachining platform, with a scan field size of 50 × 50 mm, an XY process zone of 250 × 250 mm, and a Z-axis focus of 50 mm. The XY stages have an accuracy of ±5 µm over their respective travels. Laser kerf widths down to <10 µm are possible with special optics, offering down to a spot size of 3 µm with a reduced field size of 7 × 7 mm. The system also provides for debris extraction for safety and a standard safety enclosure that meets FDA/CDRH standards.