Blue lasers reach for the sky

When the first high-power semiconductor blue laser was introduced in 2017, industry observers quickly learned of its unmatched ability to rapidly produce high-quality copper welds. Technological innovations increased the laser’s power and brightness, quickly demonstrating similar performance for stainless steel, aluminum, gold, and even brass. Years of service have established the blue laser’s reliability and stability, and now customers in a variety of industries are extending its range of applications.

Simultaneously, the technology is advancing. For example, the power and brightness of multimode blue lasers has advanced to the point where they can now integrate with standard industrial scanning systems. Increasingly sophisticated technology in turn is enabling expansion in applications, extending materials processing capabilities and improving 3D printing of metals by an order of magnitude.

The foundation

Blue lasers from Nuburu (Centennial, CO) attain their high output power by combining the outputs of scores of individual gallium nitride (GaN) diode lasers using a proprietary combination of spectral, spatial, and polarization control optics. Although the blue industrial laser was introduced only a few years ago, it is exceptionally mature because GaN benefits from the prior development of gallium arsenide (GaAs) technology. For example, GaAs diodes routinely achieve efficiencies around 70%, and GaN diodes are following that same path to rapidly increase present efficiencies. Blue laser performance depends in part on design features, but their performance rests equally on fundamental physics.

Materials processing applications benefit from the fact that many industrially important metals—copper, aluminum, gold, stainless steel, nickel, and others—absorb blue light far better than they absorb longer wavelengths. The absorption advantage leads directly to improved processing speed and product quality. Perhaps the most prominent example of that is the now well-known ability of the blue laser to weld copper up to 10X faster than infrared (IR) lasers, while producing none of the defects that are inevitable with IR.

The blue wavelength has another fundamental physical advantage. The minimum spot size in any optical system is a function of wavelength—the smaller the wavelength, the smaller the spot size. That provides another degree of flexibility for applications engineers, who can take advantage of the smaller spot where necessary or opt for longer focal-length optics where a larger spot size is acceptable.

The physical advantages, design features, and reliability and stability have all combined to create fertile ground for developing new applications for the blue industrial laser.

The impact

Consider the blue laser’s effect on lithium ion battery fabrication, a task that may require joining copper, aluminum, and steel. That range of materials is matched by an equal range of thicknesses, from less than 10 µm to more than 1.5 mm. That range of materials and thicknesses used to require a wide range of manufacturing techniques as well, such as ultrasonic welding, resistance welding, IR laser welding, and perhaps even soldering. None of these methods are said to be capable of producing all of those joints, which requires manufacturers to support several fabrication tools, along with their separate maintenance, operational, and training regimens.

Because blue light is absorbed so well by reflective metals, welding with the blue laser offers a wide process window that allows manufacturing engineers to select combinations of spot size, beam power, and weld speed suitable for joining materials of significantly different thicknesses or material compositions. As shown in Figure 1, this also means the identical laser system can be used to address the many welding stages required for battery fabrication, streamlining factory operations by reducing maintenance and training costs at the same time as increasing process speed and product quality.The next step

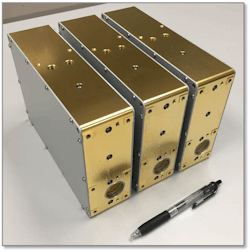

Recently, Nuburu’s AI-1500 blue laser achieved a milestone that astounded many industrial observers—output power of 1500 W with a beam parameter product (BPP) of 11 mm-mrad, an important brightness threshold because it allows the blue laser to be integrated with industry-standard scanning systems. Those systems use f-theta lenses to convert angular shifts into position changes while maximizing beam uniformity at the workpiece. Those systems also unavoidably spread the beam, reducing the power density. The initial brightness of this laser is high enough that, even after expansion through the scanner, it maintains the power density necessary for welding, below the 2.3 MW/cm2 maximum threshold for defect-free welding.

That advanced capability has opened new application spaces. For example, semiconductor devices continue to migrate to higher density, with features on the order of 20 nm. That density of circuitry creates equally high thermal density, generating heat that must be dissipated—particularly in compact devices such as smartphones, especially 5G phones. Vapor chamber cooling is an efficient method for transferring heat out of the electronics. Vapor chambers contain a minute amount of liquid, which evaporates when heated, then cools and condenses at the heatsink.

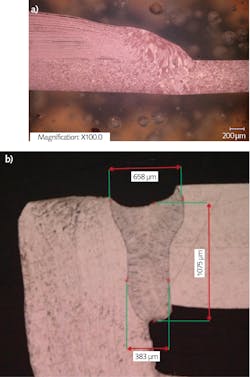

Vapor chambers consist of thin copper or steel plates joined along their edges to create a hollow pocket, with some wicking structures within. They can handle high heat flux, up to 700 W/cm2 or higher, because of the energy required for the phase transition. The interior pocket is maintained at a vacuum to optimize the physical conditions for the phase transition. The vacuum is essential to maintain high heat flux and high thermal conductivity, so the challenge is to join the 50- to 300-µm-thick plates with no defects and no compromises to the vacuum seal. In addition, the ultrathin form factor is required for integration into compact consumer electronic devices, so the joint must be uniform as well. The blue laser produces the required defect-free welds, as illustrated in Figure 3. The weld speed is 10–20 m/min, or even higher at power levels around 0.5 kW. Scanner integration means the high weld speed can be matched by rapid translation of the beam to address sequential welds at rates necessary for automated high-volume manufacturing, as anticipated for 5G smartphone production.

The blue laser is also making an impact on the rapidly growing renewable energy sector. For example, hydrogen fuel cell production is on the rise. These fuel cells consist of up to 400 individual cells, each centered around a membrane electrode assembly (MEA). Input and output ports on each cell route hydrogen and oxygen to different sides of a membrane, harvesting energy when they combine.

Currently, the perimeter of each individual cell is sealed with a compressed gasket, but gaskets can leak. Ideally, the perimeter of each individual cell would be welded, providing mechanical structure and maintaining a secure seal. Laser welding is fast and flexible, but IR lasers produce an unacceptably high level of weld irregularity, called “humping.” When the cells are stacked, this irregularity—on the order of 35 µm—leads to misalignment with the input and output ports. The blue laser welds faster than the IR and reduces humping by a factor of seven—sufficient to maintain the critical port alignment (see Fig. 4). This is another example where the quality of the weld offers new design options. In this case, welding of the cell perimeter allows a unibody design, eliminating gaskets and increasing the mechanical fidelity of the assembly.The same advantages apply to 3D printing. Both the blue laser material interaction properties and the blue laser propagation properties improve performance. High material absorption leads directly to higher part density, while the smaller spot can either be leveraged to produce parts with finer details or be exploited to extend the fabrication volume to 10X that possible with an IR laser.

Continuous technological improvements and product maturity also open up applications in new areas, such as free-space laser communications, where blue can reduce aperture diameter by a factor of three. Blue light also transmits through water about 8X better than green light. For submarine laser communications, which currently are designed around green light, blue can reach significantly greater depths or provide higher data transmission rates, or some combination of both. The enhanced transmission through water also enables higher performance lidar.

The blue laser presents a fundamental advance in laser technology. Historically, carbon dioxide (CO2) lasers demonstrated the value of the laser in various industrial settings. Then, Nd:YAG lasers leveraged their lower operating costs and improved reliability to displace CO2 in many applications, and also introduce a new set of applications. Fiber lasers, in their turn, displaced Nd:YAG lasers from some applications and made new applications practical. Now, the blue laser is reproducing that pattern. Following historical precedent, blue is supplanting older technologies for some applications, and bringing practicality to a new set of applications. Given that the roadmap for blue laser development shows a clear path to improved capabilities, it seems likely that this trend will accelerate over the coming years.

About the Author

Jean-Michel Pelaprat

Co-Founder and Chief Marketing & Sales Officer, Nuburu

Jean-Michel Pelaprat is Co-Founder and Chief Marketing & Sales Officer at Nuburu (Centennial, CO).

Mark Zediker

Co-Founder and Chairman of the Board, Nuburu

Mark Zediker is Co-Founder and Chairman of the Board at Nuburu (Centennial, CO).

Mathew Finuf

Application Manager, Nuburu

Mathew Finuf is Application Manager at Nuburu (Centennial, CO).