CRP Meccanica and Velo3D join to serve Europe

CRP Meccanica (Modena, Italy), with 20 years of experience in the field of metal additive manufacturing technology, has signed a distributorship agreement with Velo3D (Campbell, CA) as the exclusive distributor for the Italian market and an account distributor for Europe of Velo3D High-Performance SupportFree Metal 3D printers. CRP Meccanica will also provide technical assistance to customers and support for backup in case of production downtimes or production peaks.

“Our experience will help Velo3D transform the Italian and European metal 3D printing market,” says Franco Cevolini, CTO and President of CRP Meccanica. “Velo3D’s Sapphire Metal Additive Manufacturing solution is the next generation in metal laser powder bed fusion, a real game-changer that can make the difference in many high-level industrial fields.”

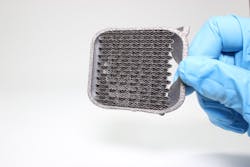

Velo3D’s additive manufacturing capabilities allow for the production of parts that cannot be made via any other technology—including most current additive manufacturing systems. It alleviates the designer from the constraints of Design for Additive Manufacturing (DfAM). The company’s capabilities enable designs with overhangs down to zero degrees, allowing the most challenging and revolutionary projects to come to life.

“CRP Meccanica’s 20 years working with metal additive manufacturing technologies have led them to appreciate the significant technological and customer benefits that our Sapphire system represents, so they are an excellent partner for us to support the Italian and greater-European markets,” says Benny Buller, founder and CEO of Velo3D.

Velo3D’s support-less metal additive manufacturing system can make the difference in the aerospace, oil & gas, and motorsport industries, just to cite a few. The advantages of eliminating support structures from the metal additive workflow are numerous, extensive and, above all, are unique to individual companies, driven by their business conditions, goals, and desires.

For more information, please visit crpmeccanica.com and velo3d.com.