How carbon dioxide lasers deliver consistent processing quality

A conventional carbon dioxide (CO2) laser cavity design operating around 9.3 µm can branch-hop from 9.35 to 9.15 µm. Since processed material absorption varies with wavelength, branch hopping leads to variable absorption—an undesirable reaction that can cause inconsistency when processing materials, particularly in applications where process repeatability is critical.

Suppressing branch hopping delivers consistent quality and increases throughput by reducing defects and associated costs. Luxinar (Kingston upon Hull, England) identified wavelength stability as critical in many applications, so the company re-engineered its range of CO2 lasers in order to reduce branch hopping, improving the performance of the lasers and delivering tangible benefits to its customers. This was achieved without significant impact on the complexity of its own manufacturing process.

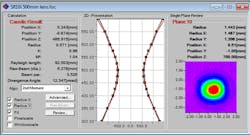

Luxinar’s CO2 laser cavity design delivers wavelength purity without compromising on beam quality; the technology produces a high-quality, circular mode. The near-Gaussian beam profile produces high energy density at the focal point, resulting in higher processing speeds when compared to other CO2 laser designs.

A round beam shape is important in cutting applications, where kerf width must be tightly controlled and consistent in all directions; this reduces the need for additional beam correction and minimizes design costs for the customer.

Luxinar’s versatile laser portfolio caters to a diverse range of industries, including consumer electronics, automotive manufacturing, fashion, food & beverage, packaging, glass, medical, and pharmaceutical. Based on a diffusion-cooled slab principle to produce a high-quality, round, and symmetrical beam, the company’s MULTISCAN laser marking systems offer an inkless method to apply text, graphics, and barcodes to a wide range of materials.

Luxinar has been at the forefront of laser technology for over 20 years, manufacturing sealed carbon dioxide (CO2) laser sources up to 1000 W and, more recently, femtosecond laser sources. To date, the company has an installed base of over 18,000 lasers worldwide in industrial application environments.