Ultrashort-pulse laser microprocessing with unprecedented precision

Posalux SA (Biel, Switzerland), which manufactures customized machine solutions for microtechnologies, has introduced a femtosecond laser that can produce the smallest hole geometries to meet the complex market requirements of applications in test electronics.

The extremely short pulse times of the ultrashort-pulse (USP) laser prevent thermal effects on the material and reduce quality issues. There is no thermal interaction between the electrons and the particle grid below 500 fs. The new Posalux machine series can drill micro-holes of less than 30 µm for production of high-precision test systems in various industries. Probe cards and test adapters for electronic components, such as ball-grid arrays, memory components, complex chip systems, or packed complete systems, can be produced with optimal support.

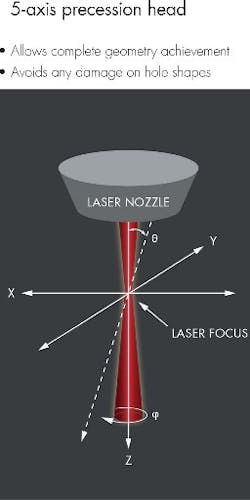

Hole geometries are not limited to conventional shapes such as cylinders. Rectangular, conical (positive and negative), or entirely different shapes can be produced as well. Even materials that are usually difficult to machine can be easily handled well with the help of USP laser technology.

Test needles are guided through a plate substrate in the test heads. They are used to measure the precision contacting. Mechanical drills are not the best solution for their manufacturer due to increased wear. Mechanical drilling does not permit hole geometries that deviate from the standard geometry in this machining process. The advantage of laser drilling is obvious. Mechanical drills that drill into hard ceramics quickly dull and need to be replaced. Laser drilling dispenses with a drilling insert that would wear mechanically. Laser pulses are also much easier to control, leading to higher control. Complex hole geometries can be implemented with perfect precision and repeated just as accurately.The Posalux system's precession head enables highly accurate and repeatable results, with the beam guidance and drilling strategy chosen to avoid any damage to the hole edge. In combination with the laser, this leaves zones unaffected by material removal or destruction. The laser used works with pulse lengths below 300 fs for excellent results.

A high-precision XY table with a total area of 300 × 300 mm permits economical machining of several parts on one substrate without re-clamping. Posalux software permits optimal implementation of customer-specific drawing files for increasing customer productivity and reduces potential error sources.

Posalux has become established in the printed circuit board industry with highly productive mechanical drilling machines. The original target group was the automotive industry, but they also offer femtosecond laser drilling machines for the electronics industry—a market segment that poses enormous demands.

For more information, please visit posalux.com.