Well, friends, it happened—the Coronavirus (COVID-19) pandemic spread from China to most of the world. No offense meant, but it drew the most media coverage in developed nations where its impact on industry, businesses, and the working population is likely to be felt for many months, and possibly years.

Here in the U.S., we are so caught up with the everyday of state-mandated lockdowns, business and school closures, and critical hospital situations that most have not focused on the long-term effects. Count me among these, but my position as a spokesperson for the industrial laser materials processing sector requires that I filter through a mass of information to try and formulate what this ‘industry’ will look like next year, and possibly longer.

Some people in the public eye have intimated that the U.S. will come charging out of the COVID-19 crisis, as we have done in less-critical times in the past (emphasis mine). I see this as a ‘feel-good’ opinion expressed in a U.S. presidential election year. Reality, a word that politicians shy away from, is that the Coronavirus pandemic ranks right up with the bubonic plague, then experienced in a nonindustrial world dominated by monarchs, not by popularly elected officials.

In my more contemplative moments, I’ve tried to envision a post-pandemic world rebuilding its infrastructure, assessing what will survive, in what shape and what will we, who lived through it, require of the new opportunities. It boggles my mind—but then again, I have never read any of the survivalist fiction, which I am told can be quite descriptive about what might be. I’m of an age where I leave this thinking to the younger generation—not the Millennials who should have passed the test during the pandemic.

Back to reality—this issue has as its theme advances in laser welding. It may be well timed, as some analysts have held that maturation in some popular laser applications may call for a rise in popularity of others. Most often favored is laser welding, which is not a new application. In fact, two of the earliest discussions on laser beam fusion welding were by Fairbanks and Adams in the Welding Research Supplement (March 1964), and Jackson, who describes packaging with laser welding in one of the early issues of Laser Focus (October 1965).

So, what has held laser welding to a modest 13–15% share of annual laser revenues? The simple answer is a lot of lower capital cost competition and the part-specific nature of the process leads to feasibility tests, part design for welding changes, and cost/part justifications.

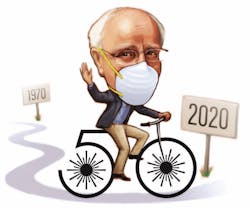

That said, the lineup of five features on advanced laser welding applications in this issue is offered as a temptation to readers to further investigate this low total heat input process that results in part-ready production of quality parts. I got into laser welding 50 years ago when I was looking for the next joining process to round out my company’s line of welding technologies. Now, all these years later, I find myself looking for the next big revenue application that will carry industrial laser processing to a higher share of annual laser revenues.

About the Author

David Belforte

Contributing Editor

David Belforte (1932-2023) was an internationally recognized authority on industrial laser materials processing and had been actively involved in this technology for more than 50 years. His consulting business, Belforte Associates, served clients interested in advanced manufacturing applications. David held degrees in Chemistry and Production Technology from Northeastern University (Boston, MA). As a researcher, he conducted basic studies in material synthesis for high-temperature applications and held increasingly important positions with companies involved with high-technology materials processing. He co-founded a company that introduced several firsts in advanced welding technology and equipment. David's career in lasers started with the commercialization of the first industrial solid-state laser and a compact CO2 laser for sheet-metal cutting. For several years, he led the development of very high power CO2 lasers for welding and surface treating applications. In addition to consulting, David was the Founder and Editor-in-Chief of Industrial Laser Solutions magazine (1986-2022) and contributed to other laser publications, including Laser Focus World. He retired from Laser Focus World in late June 2022.