System enables efficient laser drilling of rivet holes in CFRP

The automated process is based on a developed software that enables drilling strategies, which allows parameters to be continuously adjusted during the process. This enables an optimal hole quality that also meets aviation standards. Project partner INVENT GmbH (Braunschweig, Germany) was able to demonstrate that the laser-drilled holes are equivalent to conventional holes. Whole work orders can be programmed by specifying a few variables. The process is continuously monitored by thermography that regulates heat dissipation.

The system, including a new type of laser from associated partner TRUMPF Laser GmbH (Ditzingen, Germany), was planned and designed in cooperation with KMS Technology Center GmbH (Dresden, Germany), and then put into operation at LZH. The assemblies developed by KMS can be changed flexibly and adapted to different applications.

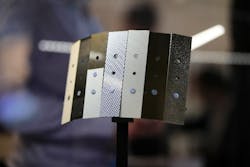

The system and the process are suitable for all carbon fiber-reinforced plastic (CFRP) types commonly used in aviation, as well as laminates with glass fiber-reinforced plastic (GFRP) top layers and copper mesh. It is also possible to drill different laminates placed on top of each other.

The LaBoKomp project, which also involved the company Premium AEROTEC GmbH (Augsburg, Germany), was funded by the Federal Ministry of Education and Research (BMBF) within the scope of the KMU-innovativ: Photonik funding initiative.

For more information, please visit lzh.de.