Fraunhofer ILT event to cover fast and reliable fuel cell manufacturing

Interest in the use of fuel cells is increasing as a result of the shift toward e-mobility and the broader adoption of renewable energy sources. To examine this development, the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; Aachen, Germany) is organizing the first Laser Colloquium Hydrogen LKH2 event, which will take place in Aachen on March 18, 2020. The event will focus on laser cutting and welding of fuel cell components and also on the execution and monitoring of the entire process chain.

At the event will be a wide range of presentations covering the use of laser technology in the realm of hydrogen, a key element of fuel cells. Some experts regard fuel cells as a smart alternative for addressing global mobility challenges due to their high energy efficiency. The use of hydrogen in fuel cells is attracting increasing attention in numerous applications, especially since it is widely regarded as a useful addition to other activities in the world of e-mobility.

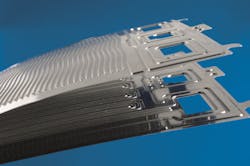

Funding approval was recently granted for a new project called CoBiP, which aims to create an innovative, turnkey solution for manufacturing high-quality bipolar plates. CoBiP covers all the key processes involved in micro-rolling and forming, laser welding, laser cutting, and coating. The goal is to create an adaptable, autonomous solution that will significantly increase the efficiency and quality of the value chain. The project “CoBiP – Continuous roll-to-roll production of bipolar plates for fuel cells” will receive funding from the German Federal Ministry for Economic Affairs and Energy (BMWi) for a period of three years and is supervised by the Project Management Jülich (PtJ).

Fraunhofer ILT is keen to provide a balanced mix of theory, research, and practice and has already signed up a number of industry representatives to speak at the colloquium. These include Gräbener Maschinentechnik (Netphen, Germany), a pioneer in the production of bipolar plates, and plasmo Industrietechnik (Vienna, Austria), a company that specializes in a number of different fields, including quality assurance for automated laser welding processes.

The first Laser Colloquium Hydrogen LKH2 will take place at Fraunhofer ILT in Aachen on March 18, 2020 (presentations will be held in German). The registration deadline for the colloquium is February 19, 2020.

For more information, please visit ilt.fraunhofer.de/lkh2.

Got laser processing-related news to share with us? Contact David Belforte, Editor in Chief, Industrial Laser Solutions

Get even more news like this delivered right to your inbox