Laser marking takes over the household appliance industry

Lasit SpA (Torre Annunziata, Italy) designs and manufactures standard and customized laser marking machines—since 2017, the company has been involved in a research and development project for laser marking the front panel surfaces of home appliance industry components.

Laser marking is the only technology that guarantees permanent marking results and this has become evident as these home appliance component companies consider lasers as the best method for marking codes, logos, text, and numbers on their components. The precision of the laser beam plays an essential role: the small size of the spot allows for more complex, microscopic, and elaborate marks for small and complex logos or geometric figures, at a level of perfection not achievable with other systems.

The home appliance industry is characterized by a wide variety of products, which are composed of irregularly shaped parts with complex and large-sized geometries, making it difficult to build versatile systems and develop the technologies needed to mark the panels, handles, and hoods.Lasit began its company-funded, six-month POLARIS project by studying the industry’s needs and then proceeding with the development and implementation of a line of laser markers able to address three main problems:

- The irregularity of part surfaces, such as the fronts of washing machines and dishwashers, where the points to be marked are located at different distances from the laser head, with a high risk of compromising marking by obtaining an imperfect result.

- Marking contrast and color competing with pad printing technology, which makes use of inks of any color.

- Creating a prototype suitable for production chains that handle more parts faster.

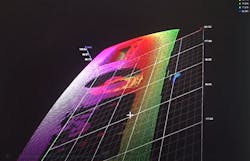

The problem of component surface irregularity—for example, the curved washing machine/dish machine front panels and handles—has been solved by using:

Marking quality was another major challenge in the implementation of the POLARIS project. In fact, even though Lasit was certain the best laser for acrylonitrile butadiene styrene (ABS) and polymethylmethacrylate (PMMA) was a 355 nm laser, a great deal of testing with other laser types of lasers had to be performed to get to the point of choosing UV and finding the ideal wavelength.

To make this laser system highly productive, it is equipped it with:

- 900 × 450 mm XY axes so even the front of a washing machine (about 600 mm) can be marked. With axes of this length, multiple marks can be placed on the work surface.

- A mechanical cam rotary table: with marking during machining, the operator (or the robot) can load the second component to be marked while the first is in the cabinet to complete its cycle.

Pad printing is the alternative to lasers currently used in the household appliance industry. This technique uses a soft, flexible pad (generally made of silicone) through which an indelible ink film is transferred from an engraved steel or photopolymer plate to the surface of the substrate.

The benefits of laser marking compared to pad printing are:

- Savings. Pad printing paints must be replaced constantly and waste materials must be disposed of. For a high productivity chain, this means very high costs. A UV laser provides 25,000 hours of operation.

- Ecology. The laser is the best technological choice from the point of view of environmental safety. Zero waste of materials means less chemical and dangerous substances for disposal and, at the same time, since the laser is a direct part marking (DPM) technology, additional paper or plastic components are not required for the product.

- Data dynamism. Laser marking allows management of the dynamism of data via software, automatically generating serial numbers and sequences.

- Resistance. Over time, pad-printed labels become damaged and codes and text are no longer visible, causing damage both in terms of productivity and company image.

Lasit is now working on the development of other laser marking systems for brand awareness that will be presented in 2020. For more information, please visit lasitlaser.com.

Source: Claudia Neri ([email protected]) for Lasit SpA, Torre Annunziata, Italy.