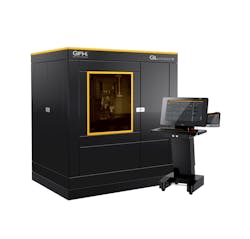

GFH laser micromachining system offers 5-axis simultaneous machining

The GL.compact II laser micromachining system from GFH (Deggendorf, Germany) covers all micromachining processes, from microdrilling to precision blanking and milling to laser turning. The 2100 × 1600 mm system was designed for 5-axis simultaneous machining, with high-precision guides to ensure 1 µm repeat accuracy in the x-, y-, and z-directions and direct linear motors for optimal movement accuracy. The machine's base and linear axis carriages are granite, reducing the material mix and stabilizing the core temperature during machining processes. All heat sources in the machine are actively cooled with water, including all axis drives, to keep the temperature level constant from the time of start-up.

Fixed or scanner optics compatible with all commercially available ultrashort-pulse laser sources may be installed through the selection of optional modules. Depending on the chosen optics and mounting, the system can process components up to 200 mm long in 5 axes.

For more information, please visit gfh-gmbh.de.