Project aims to reduce harmful emissions in laser remote processing

In laser remote processing, components can be processed at extremely high speed for sectors such as the automotive industry—however, this can result in harmful emissions that may cause lung damage. Recognizing this, a team of scientists from the Fraunhofer Institute for Material and Beam Technology (Fraunhofer IWS; Dresden, Germany) has been studying the issue as part of the IGF research project CleanRemote, aiming to reduce particles and gases in the air by means of a suction device.

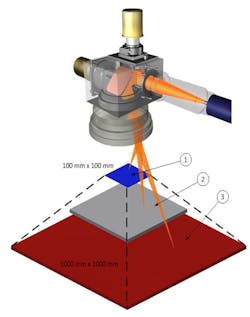

Laser remote processing has been increasingly gaining ground in the industry for several years in, for example, mechanical engineering, shipbuilding, and aviation. In the past, it was only possible to laser-machine one part after the other, but this process now allows parts up to 1 m to be cut, welded, ablated, or structured at different points simultaneously. Although this works well, there is a problem: "The process operates with a high intensity of several kilowatts within a few seconds. This produces harmful emissions such as small particles and gases," explains Annett Klotzbach, Group Manager, Bonding and Composite Technology at Fraunhofer IWS.

With a particular suction device, the risk for plant operators will be reduced. They are especially endangered when a production line is reloaded and therefore has to be opened, as particles can then escape and damage the operator's lungs. The research team initiated the study based on learning in which direction the small particles move, which are hardly visible to the naked eye."This can be quite different because some particles are larger than others. The large ones generate more kinetic energy and therefore fly higher," says Klotzbach. "In addition, the laser moves from one position to another within milliseconds by means of tilting mirrors, thereby complicating the calculations. Our partners from the Chair of Inorganic Chemistry at TU Dresden have therefore developed a flow computer model to enable us to understand the particle trajectory."

Klotzbach and her team have worked for two and a half years on the project, together with a cooperation partner. The results will now benefit those industries in which laser remote processing is of particular importance—for example, in cases in which the steel frame of a car seat is welded or a metallic surface has to be cleaned and roughened to bond carbon parts."Laser remote processing with high-performance lasers will continue to find its way into the market, especially among small- and medium-sized companies. You can benefit from our research results in order to meet the requirements of occupational health and safety and environmental protection law in the best possible way,” says Klotzbach.

For more information, please visit iws.fraunhofer.de.