Alabama Laser to discuss laser cladding services offering at FABTECH 2018

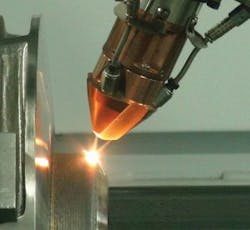

Alabama Laser's laser cladding services, which use lasers to deposit a layer of material onto a substrate utilizing either powder or wire, have utility in repairing damaged components and enhancing surface protection properties for better wear or corrosion resistance. Laser cladding offers production repeatability with stable production rates, minimum dilution with consistent chemistry throughout the clad, minimum component distortion and minimum heat-affected zone, and metallurgically bonded cladding with minimal porosity.

FABTECH booth number: C10837

To Learn More:

Contact: Alabama Laser

Headquarters: Munford, AL

Product: Laser cladding services

Key Feature: Metallurgically bonded cladding with minimal porosity

What Alabama Laser says:

View more information on the company's laser cladding services.

Locate a vendor or system integrator in our Buyer's Guide.

Share new products that you think are particularly interesting or helpful by contacting Lee Dubay, Associate Editor, Industrial Laser Solutions.