Dot forming technology achieves high-precision 3D printing

Mitsubishi Electric (Tokyo, Japan) has developed a dot forming technology that realizes high-precision shaping by combining laser, computer numerical control (CNC), and computer-aided manufacturing (CAM) technologies in 3D printers.

The technology produces high-quality 3D parts with few voids at high speed, employing a laser wire directed-energy deposition (DED) method—an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The company believes that its technology will raise productivity in a wide range of applications, such as the "near-net" (near-final) shaping of aircraft and automobile parts and build-up repairs.

With the technology, a variety of 3D shapes are possible, including hollow or overhanging shapes. It can be combined with parts produced by other manufacturing methods, making it effective in build-up repairs, and common, proven, and inexpensive laser welding wire can be used.

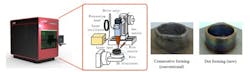

The system's components and comparative samples are shown.

The technique repeats spot forming by synchronously controlling the pulsed laser irradiation, the supply of metal wires and shield gas, and the shaping position. Shape accuracy is said to be 60% more precise when compared to conventional consecutive forming technology. Oxidation, a problem with conventional technology, can be reduced by more than 20% because high-temperature areas are limited to a narrow spot-forming area. Complex shapes can also be formed by using special CAM processes compatible with dot forming technology.

The company expects to launch a commercial version within the fiscal year ending in March 2021.

For more information, please visit www.mitsubishielectric.com.