NASA investigates femtosecond laser machining for spaceflight applications

Using a femtosecond laser, a team of researchers at NASA's Goddard Space Flight Center (Greenbelt, MD) has shown that it can effectively weld glass to copper, glass to glass, and drill hair-sized pinholes in different materials for use in spaceflight applications.

The research group, led by optical physicist Robert Lafon, is expanding its research into more exotic glass, such as sapphire and Zerodur, and metals, such as titanium, Invar, Kovar, and aluminum—materials often used in spaceflight instruments. The goal is to weld larger pieces of these materials and show that the femtosecond laser technology is effective at adhering windows onto laser housings and optics to metal mounts, among other applications.

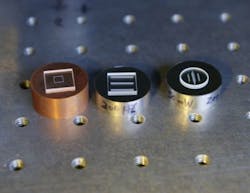

A Goddard team is using an ultrafast laser to bond dissimilar materials, with the goal of ultimately eliminating epoxies that outgas and contaminate sensitive spacecraft components. Shown here are a few samples (from left to right): silica welded to copper; silica welded to Invar; and sapphire welded to Invar. (Image credit: NASA/W. Hrybyk)

The laser energy doesn't melt the targeted material—rather, it vaporizes it without heating the surrounding matter. As a result, technicians can precisely target the laser and bond dissimilar materials that otherwise couldn't be attached without epoxies.

Another important application is in the area of micromachining. "The ability to remove small volumes of material without damaging the surrounding matter allows us to machine microscopic features," Lafon adds.

Microscopic features include everything from drilled, hair-sized pinholes in metals—an application the team already demonstrated—to etching microscopic channels or waveguides through which light could travel in photonic integrated circuits and laser transmitters. The same waveguides could allow liquids to flow through microfluidic devices and chips needed for chemical analyses and instrument cooling.

Steve Li (left), Frankie Micalizzi (middle), and Robert Lafon (right) are using an ultrafast laser to bond dissimilar materials and etch microscopic channels or waveguides through which light could travel in photonic integrated circuits and laser transmitters. (Image credit: NASA/W. Hrybyk)

Next, the team plans to compile a library of micromachining and welding capabilities. "Once we are able to demonstrate this capability reliably, we will attempt to apply it to existing challenges here at Goddard. Our initial research is showing that this technology could be applied to a large number of projects across NASA," Lafon says.

For more information, please visit www.nasa.gov.