Laser-based process repairs defects in fiber-reinforced plastics

In the aeronautic and automotive industries, repairing workpieces made of fiber-reinforced plastics (FRPs) is often less profitable than exchanging parts. To increase the lifetime of these parts and make them more eco-efficient, Laser Zentrum Hannover (LZH; Hannover, Germany), an independent, non-profit research institute, and Apodius (Aachen, Germany) want to combine a new measuring device for fiber layer orientation with an innovative laser-based repair process.

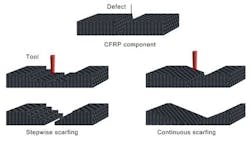

Whether or not to repair production- or operation-related defects depends on the geometry of the defective area, the tools and repair process, and the automation possibilities. By using laser scarfing and subsequent patch repair, FRP pieces can be repaired with appropriate fiber orientation. The damaged material is ablated layer by layer, either in a continuous or in a stepwise way. A precisely fitted replacement patch is used to close the defective area. Afterwards, resin can be used to infiltrate and consolidate the new fiber layers, thus strengthening the repaired area.

The challenge in laser scarfing is made more difficult by the varying thickness of the composite layers. A system from Apodius is being further developed to detect varying layer thicknesses in workpieces made of fiber-reinforced materials with a plastic matrix.

In combination with the scanner-based laser scarfing process from LZH, the new fiber orientation measuring unit achieves a higher geometrical resolution than that of mechanical ablation processes. A further advantage of laser processing, as compared to conventional processing, is that the laser is free of force contact and wear.

The goal of the project partners is to repair defects in FRP workpieces more cost-efficiently, so parts replacement can often be avoided.

The "Optical measurement of the fiber layer orientation for controlling a precise, laser-based FRP repair" (ForLase) project is being funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) within the framework of the Central Innovation Program SME (ZIM) for a duration of two years.

For more information, please visit www.lzh.de and www.apodius.de.