Laser blasting pushes technological boundaries for non-contact 3D surface structuring

ADRIEN RODRIGUES

The appeal of laser blasting—bombarding a workpiece with up to thousands of laser points per square millimeter to create a homogenous surface finish—is obvious. The process is fully digital, non-polluting, and non-contact, as no machinery makes contact with the workpiece. GF Machining Solutions is leading the way to the future with its revolutionary 3D laser surface texturing, laying the foundation for truly functional 3D laser texturing.

In terms of surface characterization on machined workpieces, surface roughness—expressed as roughness average (Ra)—is insufficient for conditions that may present proper roughness, but leave much to be desired in terms of optical appearance. Laser blasting, which uses a pulsed fiber laser to literally bombard a workpiece surface with laser energy, delivers unsurpassed homogeneity of machined surface and extreme regularity of surface characteristics.

The challenges

Despite the appeal of laser structuring, programming can be difficult and require many hours, depending on the complexity of the application. With the introduction of laser blasting capabilities that are included with its laser workstation software, GF Machining Solutions has revolutionized the world of surface structuring. Laser Design is a computer-aided manufacturing (CAM) software package specially dedicated to the company's laser machines to create machining programs for making laser textures (FIGURE 1).

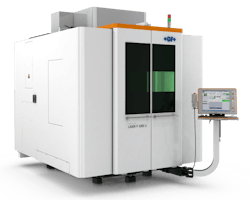

Laser blasting textures are generated with Laser Design. The operator simply tells the laser texturing machine the position of the grain, its density, and the organization of the laser points to be applied to workpiece surface. This makes it extremely simple to import a computer-aided design (CAD) file, transform it to a 3D map and apply the desired, pre-mapped texture to the workpiece. Laser Design then tells the AgieCharmilles laser texturing machine (FIGURE 2) the density of the laser points to be applied to the workpiece surface, saving many hours of programming.

Process stability and uniform quality across every reproduction of a design are also significant challenges posed by conventional surface texturing methods like sandblasting, which forcibly propels a stream of abrasive material under high pressure against the workpiece to achieve the desired surface characteristics. Often used to impart a matte texture to molds and, thus, to plastic end products, the sandblasting process has a number of productivity-impeding drawbacks in mold and die applications. It is inexact, which means repeatability and homogeneity are impossible. It also requires manual operations, which can result in inconsistent quality and scrapped parts. Moreover, it requires finding and using the right grain of sand, masking the portion of the workpiece so that only the area to be textured is exposed, and often entails involving a third-party sandblasting subcontractor, adding days to the finishing process. With the company's texturing solutions, a mold can be textured in two days without the need for masking, hand polishing, or third parties.

The solution

Complete control of the texturing process is beyond the capabilities of conventional texturing methods, leaving mold and die manufacturers with the risk of human error, scrapped molds, or poor-quality end products. This is why GF Machining Solutions introduced its Pattern Texturing Laser (PTL), a surface characterization system that takes into account a wide variety of spatial and hybrid parameters (FIGURE 3), including average groove width (Rsm), texture aspect ratio (Str), and interfacial area ratio (Sdr).

By controlling these surface characteristics, manufacturers can ensure perfect homogeneity of machined surfaces and extreme regularity of surface characteristics. This is where laser structuring plays a key role offering a genuinely revolutionary solution with the easy-to-use laser blasting. For example, two very different textures could have the same Ra, but very different Str and optical appearance.

The strides being made with GF Machining Solutions' laser are expected to enable a revolution in functional surface textures as well—for example, by generating the best surface finish according to both the characteristics of a mold and the injection material. That will make it possible to boost productivity and end-product quality by taking full control of processes like demolding.

Applied research continues

GF Machining Solutions is involved in applied research with industrial partners and academic institutions, such as the School of Engineering and Architecture of Fribourg (Switzerland), to validate the potential of laser structuring to increase the productivity of plastic injection molding. The research is already demonstrating that appropriately selected laser structures can reduce injection cycle times with several types of plastic without compromising surface quality.

ADRIEN RODRIGUESis the Laser Product Manager for GF Machining Solutions, Geneva, Switzerland; www.gfms.com.