The new Cincinnati Modular Material Handling System (MMHS) from Cincinnati boosts productivity of CL-800 series dual-pallet laser cutting systems, reducing cost per part and allowing unattended operation for up to three shifts via automated load/unload of raw materials and finished parts. The MMHS optimizes material flow and laser burn time, and the overhead rail design allows shops to tailor automated sheet and part handling to existing floor space and today's processing needs, while assuring easy system expansion to serve multiple laser cutting systems as laser activity grows. System components include a cell controller, transporter, safety system and optional over/under carts capable of carrying up to 12,000 lbs. (5443 kg) each.

The MMHS installs quickly and the simple design is easily integrated into the laser cutting system. A touch-screen controller sends programs to the laser and controls all automated and manual functions of the material handling system, while logging inventory depletion. Cincinnati Programming and Nesting Software is integrated with the MMHS and laser cutting system to optimize material usage and determine how much material is required for each task.

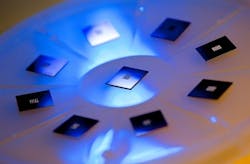

The transporter uses vacuum cups to deliver 5 ft. x 10 ft. (1.5 m x 3 m) or 6 ft. x 12 ft. (2 m x 4 m) sheets to the laser, and a sheet peeler ensures one-sheet-at-a-time delivery to the laser. Servo-controlled "fingers" unload finished parts from the laser to the over/under carts or floor pallets. The transporter handles sheet thicknesses from 20 gage (.9 mm) to .75 in. (19 mm).

The MMHS complies with ANSI B11.19-2003 safety standards, and mutable zones allow safe access into work areas without disrupting production. It is available with all new CL-800 series laser cutting systems.