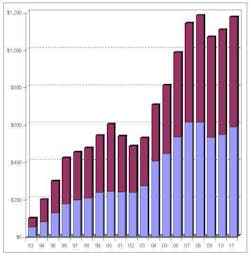

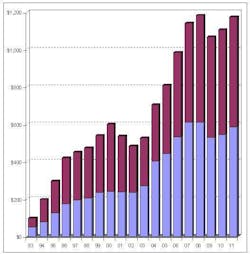

Revenues from additive manufacturing

Fort Collins, Colo. – The demand for products and services from additive-manufacturing (AM) technology has been strong over its 22-year history. The compound annual growth rate (CAGR) of revenues produced by all products and services over this period is 26.4%, according to Wohlers Report 2010. The CAGR slowed to 3.3% over the past three years, with 2009 being the slowest in many years by far. The chart shows the rate of growth/decline since 1993. The bars for 2010 and 2011 are forecasts.

Unit sales remain relatively strong due to the impact from very low-cost machines. The 3D printer market segment grew by nearly 18% in unit sales, yet the segment experienced a sharp decline in revenues – the first time ever since tracking this market segment.

The additive-manufacturing industry has tremendous untapped potential, especially when considering the opportunity in custom and short-run production. Producing parts for end-use products is more challenging than models and prototypes, so this application will take time to develop. It is expected to drive revenues from AM products and services to impressive levels in the future.

Wohlers Report 2010 is a 250-page global study that focuses on the advances in additive manufacturing worldwide. A detailed overview of the report, as well as additional information on the market and industry, are available at http://wohlersassociates.com.

Terry Wohlers talks about changing a name

Old habits die slowly. Case in point: Transitioning to the term “additive manufacturing.” That’s now the official name of what some refer to as rapid prototyping, freeform fabrication, and a host of other names. Additive manufacturing is the official name …. according to whom? The ASTM International F42 Committee on Additive Manufacturing Technologies. The group put a lot of thought into it, first selecting AM as the favorite for the name of the committee. It then carefully defined it. The term was not my first choice, but I made the decision to accept, use, and encourage others to use the term, which was decided by consensus – a standards-making process that ASTM has refined over the past 100 years. I decided that if scores of professionals across four continents can agree on it, the term should hold weight and be take seriously.

Defining AM required input, changes, constructive argument, more changes, etc., etc. Eventually, the members of F42 voted on and approved the following: “Additive manufacturing (AM) is the process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies. Synonyms: additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, and freeform fabrication.”

The definition includes all applications of the technology, including the making of models, patterns, and prototypes for form, fit, and function; mold, die, fixture, and assembly tooling; and custom and limited-edition products, replacement parts, and short-run and series production. Rapid prototyping is the most popular application of AM technology, but it is only one of many.

I hope you can be a part of this change. If you’re uncertain, ask, “Do I want to be a part of the past or a part of the future?” Someone once said that the use of “rapid prototyping” as the generic term is so “1990s,” which is true. Join the 21st century and also consider joining the ASTM F42 standards effort. The group has identified, defined, and approved 27 AM-related terms, but this is only a start. If terminology is not your thing, consider getting involved in one of the other F42 activities. They include the development of standards around test methods, processes, materials, and design (including data/file formats). Retire old habits and help advance the additive manufacturing industry to a new level.

Note: Wohlers Talk is a blog that offers views, perspective, and commentary on rapid product development and a wide range of other topics. More than 200 commentaries have been published. To view them, visit http://wohlersassociates.com/blog.