Reflection diagnosis for laser plastic welding

Erlangen, Germany – As of autumn 2010, reflection diagnosis will be available as an option on LPKF Laser & Electronics AG welding systems.

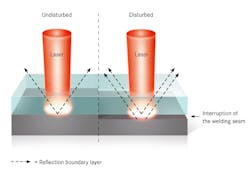

Reflection diagnosis makes use of the physical effect of light reflection at boundary surfaces. Before welding, there are in effect two boundaries between the components. When light—also laser light—impinges on these boundaries, a certain amount of light can be reflected. Areas that have been welded together have no such double boundary and the amount of reflected light is reduced.

This method also allows the quality of a welded seam to be evaluated during the actual welding process. The integration of the reflection diagnosis system into the laser head gives the LPKF LQ-TwinWeld3D hybrid welding system an advantage in the marketplace for sensitive components, such as car tail lights and solar panels, helping to reduce reject rates and deliver robust quality documentation for each individual component.

“Reflection diagnosis gives us an innovative measurement tool to verify successful welding," said Frank Brunnecker, VP, laser welding at LPKF Laser & Electronics AG as he welcomed his latest patent, the technical implementation of which once again demonstrates, he said, the in-depth competence of LPKF in laser plastic welding.

LPKF Laser & Electronics AG is an international specialist company for laser material processing systems. The LaserQuipment welding systems from the Plastic Welding Division in Erlangen/Germany are mainly used by the automotive industry, the medical technology market, and the consumer goods sector. Using laser plastic welding to join components together is gaining in importance around the world.

For more information, contact: [email protected]