Lasers for medical device technology

Aachen, Germany – The Fraunhofer Institute for Laser Technology (ILT) is presenting a laser-based process to manufacture tailor-made implants at COMPAMED, the international trade fair for high tech solutions for medical technology. In addition, the experts will be showing to the professional audience the processes to laser weld plastics for medical components without leaving welding seams as well as to laser polish metal.

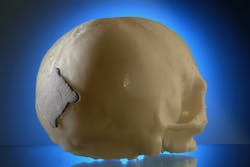

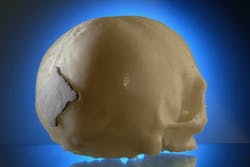

At COMPAMED (Dusseldorf, Nov. 17 to 19, 2010), Fraunhofer ILT is presenting tailor-made biodegradable implants that were produced using selective laser melting (SLM), an additive laser manufacturing process. Thanks to their interconnective pore system, these implants made of ß-tricalcium phosphate enhance stromal and vascular cells' ingrowth ability. In addition, porous implants made of a titanium alloy, manufactured using SLM, will be shown.

Another area where lasers can be used in medical technology is the polishing of metal. In this case, the laser beam melts the material surface to a depth of about 5 microns. The surface tension ensures that the fluid metal flows evenly and dries smoothed. This process developed by Fraunhofer ILT is interesting for all medical-technical components with metallic surfaces that need to have an extremely low roughness. Manufacturers can see examples of such components at the stand.

For medical-technical products made out of plastics, the Fraunhofer ILT will be presenting an efficient welding process. The TransTWIST process (transmission welding by an incremental scanning technique) allows two transparent joining partners to be connected together in an overlap by means of laser radiation without the need for additional absorbers. In contrast to conventional laser welding, expensive pretreatment steps can be omitted. The end user thus saves time and money. With the laser welding machine TransTWIST, extremely high-quality welding seams can be made, which fulfill all established requirements upon the end result as to invisible welding seams and expansion in the heat affected zone. A main area of application is in medical technology, especially microfluidics.

Contact: For microjoining - [email protected], for polishing - [email protected], for ablating and joining - [email protected]