Research team to develop laser processing methods for multifunctional composites

A team of researchers at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; Aachen, Germany) is studying and developing laser processing methods for economical joining, cutting, ablation, and drilling of composite materials, especially in the context of their integration into existing process chains.

"Mechanical processes in separation technology such as milling, sawing, or water-jet cutting as well as bonding—when materials are joined—can be replaced by laser processes, which significantly increase the efficiency and quality of overall construction processes," explains Alexander Olowinsky, Group Leader of Micro Joining at Fraunhofer ILT.

Plastics and metals each have specific properties, such as malleability, strength, or thermal conductivity, all of which can be combined in hybrid components. However, making these hybrid compounds requires that metal surfaces first have to be prepared. This can be accomplished, for example, by microstructuring with a continuous-wave (CW) laser or micro- or nanostructuring with ultrashort-pulsed (USP) lasers and different machine concepts.

The lightest metallic construction material, magnesium, is characterized by a particularly high thermal conductivity. Together with the Institute for Plastics Processing (IKV) at RWTH Aachen University, Fraunhofer ILT is developing laser processes to microstructure magnesium, which will subsequently enable very stable and form-fitting connections with various thermoplastics in hybrid injection molding processes.

A microstructured hybrid beam made of magnesium and short glass-fiber reinforced plastic (PP-GF30) is shown. (Copyright: Fraunhofer ILT, Aachen, Germany)

For such processes, a single-mode fiber laser (at 1064 nm) produces precise undercuts in the magnesium surface at area rates of up to 1000 mm2 per second—these undercuts can be filled with plastic in the subsequent hybrid injection molding process. "For short glass fiber-reinforced plastic, we have developed hybrid connections with high tensile shear strengths up to 22.4 MPa—the components are not only extremely light, but also at the same time extremely durable," explains Christoph Engelmann, team leader of Plastics Processing at Fraunhofer ILT. Moreover, since no adhesives are needed, aging processes also take place more slowly than with conventionally bonded joints.

In principle, all thermoplastic materials used in injection molding are suitable. They open up a wide range of possibilities for connecting components together and integrating functions, which the manufactured hybrid components later offer and which cannot be produced in pure metal construction.

When lasers are used to cut thermoplastic composite materials, in particular carbon-fiber reinforced plastics, the process design generally aims to generate the smallest possible heat-affected zone. At the same time, it should maintain a productive and short processing time: Repeated, fast scanning of the laser beam along the cutting path successively removes material and goes easy on the material. "By continuously tracking the scanning field, we are able to use this procedure for large components," explains Dr. Frank Schneider, project manager for Macro Joining and Cutting at Fraunhofer ILT.

Trimming of a hybrid car roof bow made of glass and carbon-fiber reinforced plastic is shown. (Copyright: Fraunhofer ILT, Aachen, Germany)

Laser power, scanning speed, and the cooling time between the scans influence the heat-affected zone and the processing time. The scientists are optimizing these parameters and, thus, determining the best-possible settings for the material, which can also be adapted within a component in the case of hybrid parts made of a material mix. Even if materials as diverse as glass fiber- and carbon fiber-reinforced plastics (CFRPs) should be separated but are stacked on top of each other, cutting can be done in one step--precisely, efficiently, and without tool wear, thanks to the availability of CW high-power lasers with excellent beam quality.

In the lightweight sector, the integration of functional elements in CFRP structural components is often carried out via threaded inserts—for example, in preforms for components in the automotive and aircraft industries. For this purpose, the inserts are placed in a form-fitting manner into mechanically drilled components and are then glued. The quality and strength of the joint depend largely on the accuracy of the drilled laminate and the bonded joint.

Related: Fraunhofer ILT develops laser-based process for constructing lightweight battery packs

Particularly durable and high-quality compounds are formed when the unimpregnated carbon-fiber textile is drilled by means of USP laser radiation, into which functional elements are subsequently inserted in a form-fitting manner. Laser scanners also make it possible to form demanding drilling contours such as star-shaped holes and, thus, the integration of load-adapted inserts. In the later infusion process, the matrix acts as an adhesive between the carbon fibers and the insert, eliminating the need for additional adhesives.

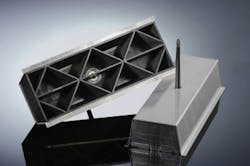

A USP laser beam-drilled carbon-fiber preform with a star-shaped hole and positive-fit metal insert is shown. (Copyright: Fraunhofer ILT, Aachen, Germany)

Thanks to USP laser beam machining, both preforms and consolidated CFRP components can be drilled at high quality. "The primary evaporation of the material can prevent thermal or materialographic damage in the laminate or fibers," explains Stefan Janssen, team leader of Laser Drilling and Precision Cutting at Fraunhofer ILT. The process times from typically a few seconds to one minute and the high level of automation also support productive use of this process in CFRP component production.

Experts from Fraunhofer ILT will be presenting details and new developments in their work at the joint AZL booth in Hall 5A/D17 at the JEC World event to take place March 12-14, 2019, in Paris, France.

For more information, please visit ilt.fraunhofer.de.